This is one of several pages relating to the history of the automatic totalisator, its invention in 1913, the inventor George Julius and the Australian company he founded in 1917 which became a monopoly ( later, part of an oligopoly ) in this field. This page relates the history of the Australian company, Automatic Totalisators Limited. This is a history only, non commercial page. If you wish to start from the beginning then go to the index .

Copyright © 1997 Email - totehis@hotmail.com

| Automatic Totalisators Limited - later ATL |

Automatic Totalisators Ltd., a public Company was formed in 1917 to manufacture, install and operate Totalizators throughout the world. By 1970 with few exceptions, every major racing centre in the world used these Australian Totalizators, which were in service in 29 countries. The Automatic Totalizator was invented by the late Mr. George Julius (later Sir George). In 1913 he installed his first totalizator on Ellerslie Racecourse in N.Z. and the second at Gloucester Park in Western Australia in 1916. The installation at Ellerslie was the first automatic totalizator in the world and although it looked like a giant tangle of piano wires, pulleys and cast iron boxes and many racing officials predicted that it would not work, it was a great success.

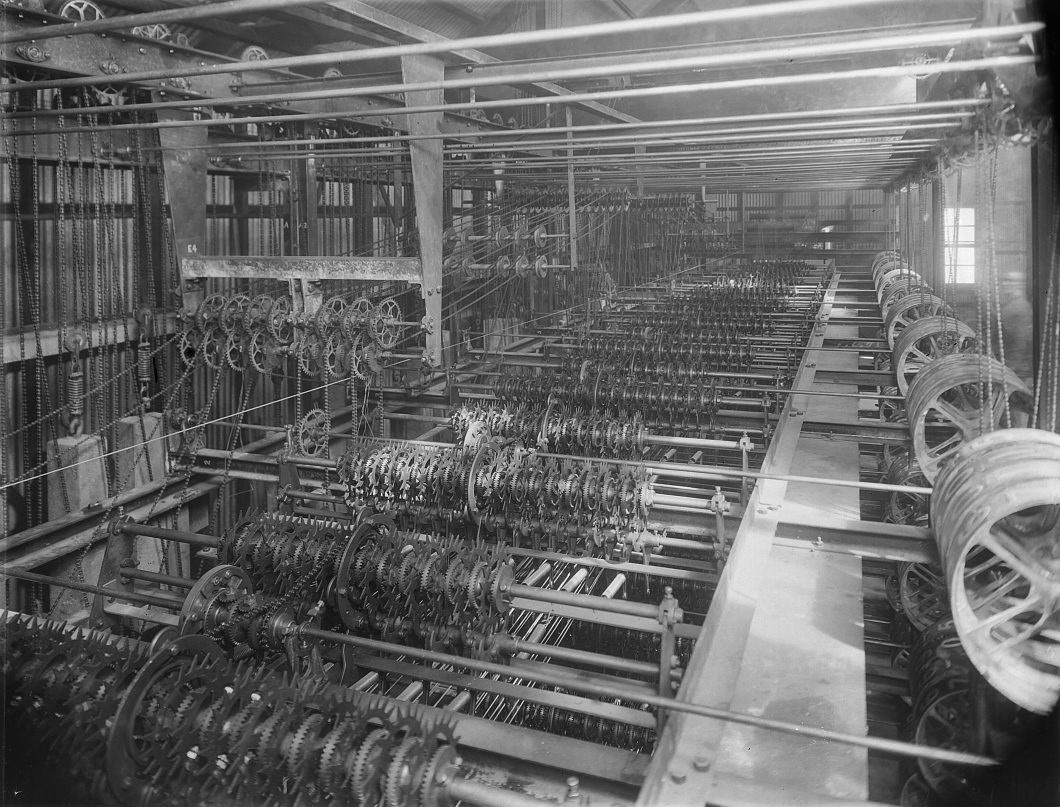

These early automatic totalizators were completely mechanical and consisted of Ticket Issuing Machines coupled to Drum Indicator Adder Units, all housed in the one building for one pool only. Miles of flexible wire cables connected the Ticket Issuing Machines to the Indicator/Adder Units. A considerable length of bicycle chain ran over sprockets and heavy cast iron weights were used for drive power.

In 1917, after the Company was formed further research led to the introduction of electrical power and the miles of flexible wire cable were replaced by simple electrical conductors which operated solenoids both in the Ticket Issuing Machine and the Indicator/Adders. This was a major development because now the Ticket Issuing Machines no longer had to be close to the Indicators.

By 1920 equipment was installed on a total of seven racetracks in Sydney, Brisbane and Newcastle in Australia, and Auckland in New Zealand. The equipment was very bulky , employing the principle of one Ticket Issuing Machine to one Escapement Wheel, which limited the number of Ticket Issuing Machines to the number of Escapement Wheels it was possible to build into the combined Adder Drum Indicator Unit. Invariably these installations were confined to one building and no attempt was made to connect buildings by underground cable. The Indicators provided for one Pool only, but the fields were large. For example, at Randwick, the equipment provided for 42 starters. At this stage all the equipment was manufactured at Mr. Julius' home in Darling Point, Sydney, or in a backyard garage nearby.

Until the early 1920s the equipment was made for one Pool only and when you went on a racetrack you bet on the "Tote". The net Pool was divided up into three parts giving the winner 60 % and each of the 2nd and 3rd horses 20 %. At this stage there was a separate tote in each enclosure, not connected in any way with each other, so that, where three enclosures existed, as at Randwick, three different sets of dividends were declared.

In 1922 the old single "Tote" was superseded when Win & Place pools were created and the same year the first Totalizator equipment for Win & Place betting was installed in Perth, Western Australia. From then on, with few exceptions, all racecourses installed Win & Place equipment. The Ticket Issuing Machines were divided so that some sold Win and others sold Place. The method of calculating the dividend for the Place pool was such that the total money invested on the placed horses was taken out of the net pool and the remainder was divided by the number of dividends to be declared and this figure was divided by the units bet on each placed horse. During the next ten years the Company installed equipment on 27 racecourses in India, Ceylon, Malaysia, Singapore, France, New Zealand and Canada. The biggest order during this period was equipment for Longchamp, Paris, in 1926, and this was the largest order undertaken by the Company until the order for Caracas, Venezuela in 1957, over 30 years later.

The French order meant considerable design work, as now, for the first time, the Adders were to be divorced from the Indicators. The Adders had to have a capacity of a minimum of 273 Ticket Issuing Machines through a Distributor connected to one Escapement Wheel, over 35 Escapement Wheels where needed on each Adder. The Adder design was a feat of mechanical engineering, all values and transfers being mechanically linked. The Ticket Issuing Machine design also was a remarkable piece of engineering and saw the introduction of a machine to sell both Win & Place tickets from the one machine. This was a big step forward and proved to be one of the main features for many years to come. The equipment for Longchamp was manufactured in the factory at Alice Street, Newtown, N.S.W. except for the Ticket Issuing Machines, which were made in Paris under supervision.

Up till this time, only pool figures were displayed to the public but, in 1927, Mr. Julius came to light with automatic odds, which was probably the biggest milestone in the Company's existence. Models of this type of equipment were taken to London and North and South America. In 1930, Automatic Odds Equipment was installed at Harringay Dog Track in London, and the following year Automatic Odds Barometer Indicators were installed at Flemington, Caulfield, Moonee Valley and at Williamstown Racecourses in Victoria, Australia. It is as well to point out here that at this stage legislation had only just been passed to permit totalizator betting in the State of Victoria and that these installations were done in the middle of the depression years and represented the largest single bulk order from a group of racecourses. During this period an associate company, Totalisators Ltd, was formed in London to manufacture, install and operate totalisators in the United Kingdom, Europe and Africa.

On the first installation at Harringay Dog Track, in London, odds were displayed on a Digital Indicator and a pointer, like the hands of a watch, indicating the odds on the particular starter. The mechanical analogue Odds Computer was an ingenious device which undoubtedly put the company in the forefront as Totalizator Engineers.

Immediately after the depression, Automatic Odds installations went to India, New Zealand and right throughout Australia. The first installation in the United States was made in 1932, when equipment was installed at Hialeah Racetrack in Miami, Florida. The second world war in the late 1930s put an end to totalizator manufacture and installation for almost 10 years. During the war years the factory, which had moved to Chalmers Street Sydney in 1933, went into full production for the Department of Defence and later the company expanded the munitions work to include tooling.

The knowledge gained in general manufacture and tooling during the war years was to serve the company in good stead immediately after the war, when it threw all its resources into tooling and manufacture of new totalizator equipment. In later years, when tote tooling work eased off, the toolroom turned to commercial work. This side of the business expanded rapidly until, the company had one of the largest commercial tool rooms in the southern hemisphere established on their premises at Meadowbank.

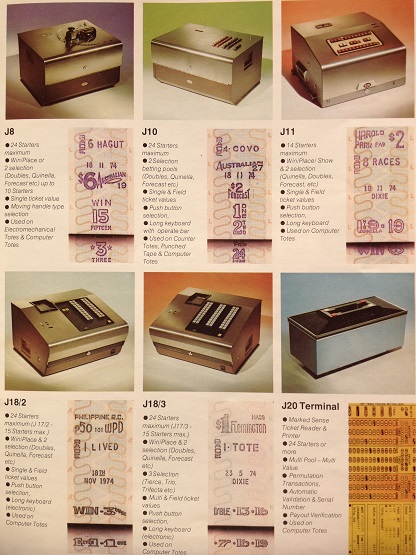

In late 1945, the company started in earnest to design totalizator equipment for post war use and, at this time, the J8 ticket issuing machine was born. The J8 proved to be a durable addition to the Automatic Totalisators terminal range. Up until October 1995, The Royal Turf Club of Thailand continued to use J8s as the on-course ticket issuing machine. Along with the ticket issuing machines, there was need for new designs in Mechanical Analogue Computers, Adders, Odds Relay Units and Indicators. The factory therefore, continued on at war time tempo for many years, in an attempt to fulfill the orders that kept rolling in. The company moved to the factory at Meadowbank in 1947.

A ticket printed on a J8 ( Animation above )

A ticket printed on a J8 ( Animation above )

The first batch of J8 Win, Place ticket issuing machines was installed on Randwick Race Course in 1948. The delivery of these ticket issuing machines to Randwick released a quantity of the existing J6 ticket issuing machines for despatch, along with some 2-shaft adding units, to the United States for use at Randall Park Racetrack. This was a stop gap move and in 1950 the company installed new equipment on this racetrack. That same year an associate company, Automatic Totalisators (U.S.A.) Ltd. was formed to purchase equipment from the parent company and lease it to racetrack operations in the U.S.A. This Company became a subsidiary and by 1967 the company had 23 operations in the United States and Canada.

In 1948 the first mobile tote was manufactured, and was used in the Sydney metropolitan and near country areas. In later years many more of these units were manufactured.

At this time the company entered the busiest period of manufacture and installation in its life. Simultaneously it was manufacturing and installing equipment for racetracks in India, South Africa, Australia, New Zealand, North and South America. In all, it installed equipment in 99 race tracks throughout the world between 1948 and 1955. The bulk of this equipment was for Win, Place pools only. At this stage, it catered for doubles and quinella pools with small fields only, but very soon after was confronted with the possibility of having to provide equipment for 24 starter fields.

The first real challenge came when all the Melbourne racetracks wanted combination pool equipment. In 1955 the company conceived the idea of using the principle of punched tape for recording investments on these pools and, in 1956 the company provided equipment in Melbourne using newly designed J10 24 starter ticket issuing machines, along with punched tape recorder and electronic readers. This equipment marked another milestone in the history of progress and within several years, this punched tape combination betting equipment was installed in South Africa, Malaysia, Singapore, and every capital city in Australia.

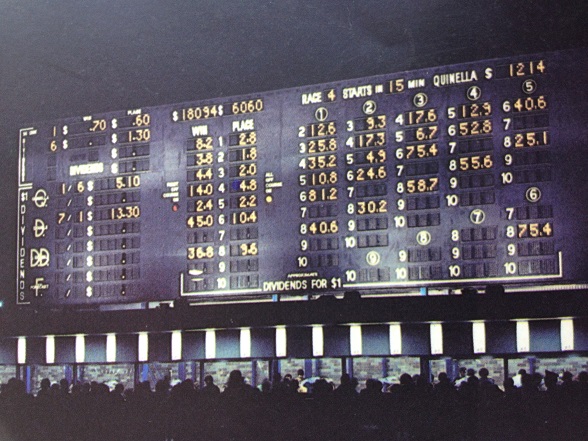

The company advanced into the sixties installing conventional equipment throughout the world, with the betting trend swinging more towards the combination betting pools than ever. Public indication of the state of betting in these pools had always been a problem. At Harold Park, the company installed a quinella indicator with 66 combinations, that is, quinella odds for 12 starters.

In 1964 the company took over Bell Punch New Zealand Ltd purchasing all their equipment in the field, taking over the operation of all their installations and this company was later known as New Zealand Totalisators Limited.

Webmaster's note:

Following is an extract from an email received in December 2014, from Chris Robertson, who I regard as an expert on totalisator companies and their products. I have placed it here as it relates to Bell Punch and ATL (Automatic Totalisators Limited):Automatic infield lamp box odds indicators were installed in 1965 on all the Melbourne metropolitan racecourses, including the new racecourse at Sandown Park. In some cases the barometer indicators were retained, and the company designed the equipment to allow these indicators to work in parallel with the lamp box indicators. Here the company had a link of the old with the new, namely the 1931 barometer indicators and the 1965 odds lamp boxes.I actually saw Bell Punch machines and ATL J8 and J11 TIMs working together at the same race meeting in Greyville, Durban in September 1983. It appears Bell Punch had quite a presence in New Zealand as well. In Victoria they were machine of choice of both Control Systems and Greyhound Totalisators. The Ballarat Greyhound Club bought Greyhound Totalisators Bell Punch machines in 1975 when ATL's mobile computer tote became favoured by the Melbourne greyhound tracks.

New control, access and aggregating equipment was also supplied to Melbourne and installed in an air conditioned van which moved from track to track. At the race track, the equipment was plugged into the racetrack facilities, plus an off-course console which allowed the off-course investments to be stored in the van so that, for odds and dividend calculations, the off-course investments could be added to the on-course investments.

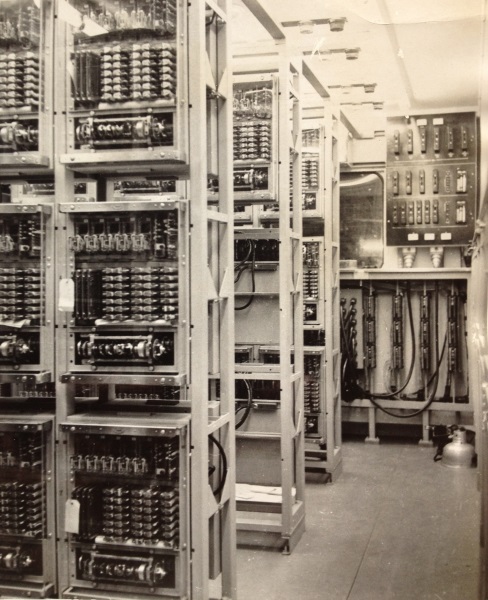

In 1966 Automatic Totalisators Ltd took the racing industry into the electronic era with the development of the World's First Computer Totalizator System, for the New York Racing Association, which handled a totalizator turnover each season of over $700 million. This system had 550 type J11 Ticket Issuing Machines, two Infield Lamp Box type Indicators and twenty Auxiliary Odds Lamp Box Indicators. This installation was the culmination of many years of research and development. The equipment was portable and was moved from Aqueduct to Belmont Park and Saratoga, the northern tip of New York State, where a smaller operation was conducted making a total of 234 race day operations per year. Premier Equipment Pty Ltd, a subsidiary maintained and operated the equipment for all 234 race meetings.

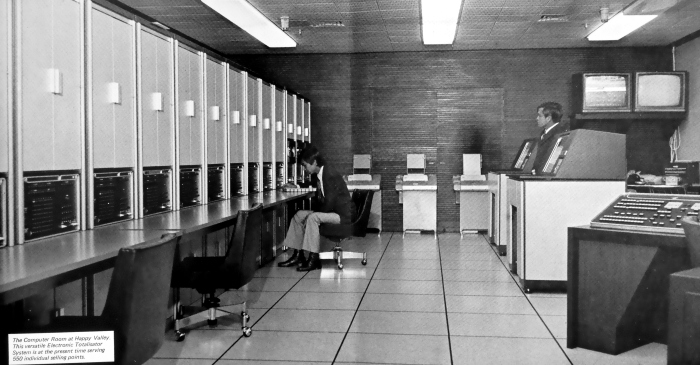

Inspired by the success at Aqueduct, further research and development led to a more compact and economical Electronic Totalizator System using small General Purpose Computers with all the features of the Aqueduct system. This new electronic totalizator made its debut in November,1968 at a harness track in Georgetown, Delaware, U.S.A., and at Happy Valley racecourse, Hong Kong.

The last Julius Totalizator ceased operation at Harringay London in 1987.

Postscript - It is now June 2005 and I have just received mail from Caracas. I was informed that the Julius tote there is still in operation. After 48 years of operation I have been asked if I have any information on how to make adjustments to the system to bring it up-to-date!

ATL makes Electronic Totalisators, Electro-mechanical Totalisators, Portable Counter Totalisators, Punched Tape Combination Betting Equipment, Odds and Dividend Computers, Totemobiles, Ticket issuing Machines, Display Indicators, Coded Ticket Paper, Photo-finish and Race Timing Equipment, Consoles, Totalisator Power Supply Equipment, Turnstiles, Tools and provides specialised services.

It has more than 200 installations on racecourses in 30 countries ...

Philippines, South Africa, United States, New Zealand, Hong Kong, Venezuela, Singapore, Indonesia, Australia, Scotland, Thailand, Columbia, Malaysia, Rhodesia, Trinidad, England, Pakistan, Jamaica, Nigeria, Canada, France, Ceylon, Burma, Brazil, Spain, Iraq, Eire (Ireland), Ghana, Sweden and India.

But for all this, ATL has a lot to learn ... about dissatisfied customers.

It has never had one yet!

| The Toolmaking Division Of Automatic Totalisators Limited |

Following is an article from Tote Topics magazine number 18 dated June 1968

The name Automatic Totalisators Limited, quite naturally, sells to the majority of the general public the fact that we are a company whose interests revolve around the racing world, thus embracing our four legged friends, racetracks and the human elements of gambling. But, how many, with the exception of those who are engaged in or have been associated with, the business of volume production, would associate this name with something seemingly as foreign as the manufacture of precision tools and gauges for commercial use.

The fact is, we are commercial toolmakers and to explain this somewhat surprising set of circumstances, let us look back into the history of A.T.L., in particular, the period during and after the last war.

During the war, the toolroom was employed in the manufacture of tooling for Munitions, a factor which proved of considerable value in post war years, when the accrued knowledge and machinery we used to considerable advantage in the manufacture of Totalisator Tooling. At this period, it was also found that the production requirements of industry were increasing and it was this factor which prompted the move into an additional field to the Totalisator Market and Automatic Totalisators Limited this became toolmakers to the trade.

To the uninitiated, a toolroom is a place where hammers, spanners etc., are manufactured. This obviously is not the case, for while these items could be made quite adequately in the toolroom the individual cost would be astronomical as these items are basically volume production. However, the tools from which these items are produced, could be, and are made quite successfully and economically in our toolroom.

To describe our facilities and function in detail, would be both lengthy and boring, but as a starter, let us say we are specialists in the manufacture of high class tooling such as Press Tools, Mould, Jigs, Fixtures and Gauges. Those who are familiar with tooling will readily see that this modest statement virtually covers the entire range of tooling requirements anyway.

The tooling from which everyday items are produced is employed by the manufacturer in the production of items whether they be from plastic or metal. Items such as body panels for cars are produced from a press tool. The telephone handset is produced from a plastic mould and high precision gauges are used to ensure the intricate dial mechanisms, incorporated in the phone, comply with specifications laid down by the P.M.G.

To facilitate the efficient manufacture of this type of high class tooling, good quality machine tools are a necessity. These fall into two basic classes, namely:

(a) The conventional or basic machine, such as lathes, milling machines, surface and cylindrical grinding machines and drilling machines etc.

(b) The more sophisticated machine tool which is used for the specialised operation, so necessary to enable compliance with today's requirements. Our range of this type of equipment includes machines such as Jig Borers, Jig Grinders, 3 Dimensional Pantographs, Electrical Discharge Machines and Optical Profile Grinders.

The need for this type of specialised equipment has increased dramatically over the past ten years, a condition which can be more readily appreciated if we look at the everyday items such as the modern motor car and its associated fitting, lawnmowers, T.V. sets, the telephone with its associated switchgear. All these items, and many more too numerous to mention, have been accepted as part of our way of life, but very few people, quite naturally, would appreciate the problems associated in producing these items, or to be more exact, give any thought as to how they are produced.

To ensure we produce the desired result in the manufacture of all types of quality tooling we have a Metrology Section,k through which all work must pass and be certified as correct to drawing dimension. This section is approved by the National Association of Testing Authorities and Department of Civil Aviation, to certify that work performed in the tool-room or for that matter, work performed by anyone is acceptable at the standards laid down by these various departments.

All inspection work is carried out in air conditioned surroundings, utilising the most modern metrology equipment available. The Commonwealth Government would be our largest customer in this field, and constantly request our certification of various types of gauges, whether we have made them originally or not.

The combination of skill, high precision equipment, and the reputation of being able to produce a quality tool, whether it be press tool, mould, jig and fixture or gauge, has given us the right to add the bi-line of Tool-craftsmen to Modern Industry to the name of Automatic Totalisators Limited.

| Display Equipment |

A.T.L's Computer Totalisator System is built around the concept of total service to the betting public. It fulfils this concept with the ultimate in speed, accuracy and reliability. A.T.L.'s Totalisator Systems reach out to the racecourse public through a superb range of display equipment. A.T.L Odds Indication equipment provides up to the minute betting information instantaneously, clearly and with the complete precision necessary to build up the billion dollar turnover which the combined A.T.L computer systems around the world handle each racing season.

Automatic Totalisators Limited has developed three main types of Odds Indicators:

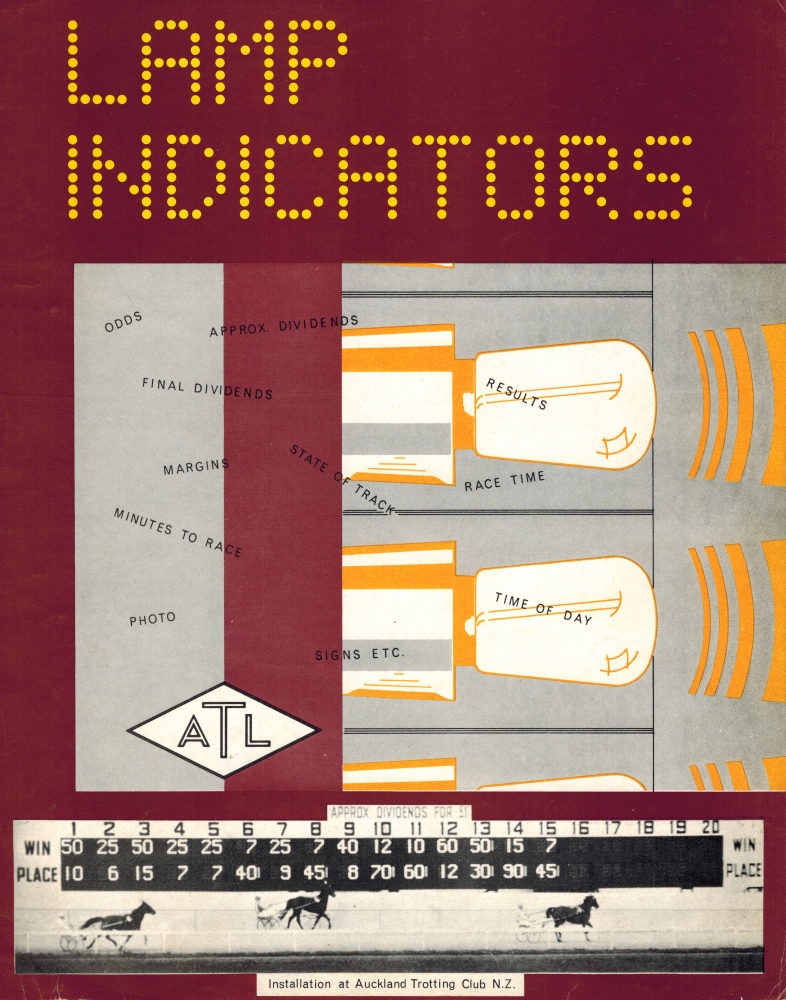

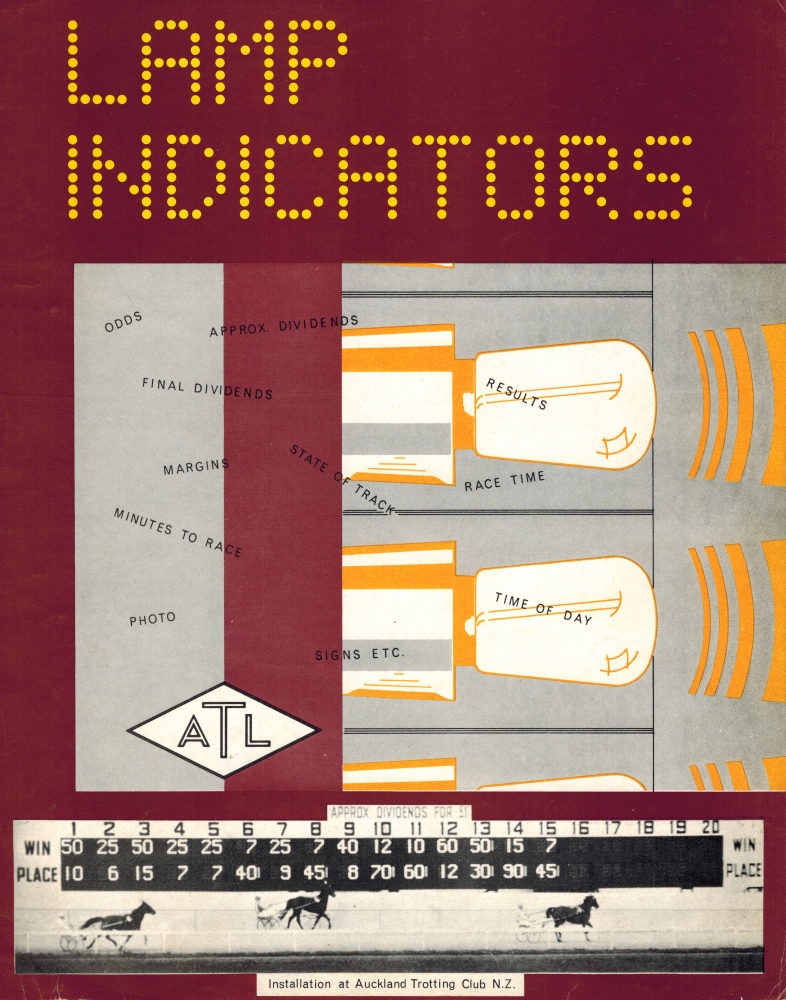

A.T.L Lamp Box Indicators, the most suitable form of indication for mass public viewing are attractive landmarks among the top racecourses of the world.

ATL Lamp Box or Panel Indicator Brochure Cover

Intensive racecourse surveys by A.T.L technical staff ensure they are strategically situated for the maximum convenience of the public and where they will blend most effectively into the course surroundings and traffic pattern.

Lamp Panel Indicator at Wentworth Park Greyhound track Sydney

A.T.L Seven Segment and Closed Circuit TV indicators provide an efficient and economical display in confined areas such as betting halls, and restaurants.

A.T.L's Computer Totalisator Systems demand the most speedy, reliable and accurate indication possible to meet the greatly increased turnovers they can handle.

That is why the Company developed its own display equipment.

After 58 years of indicator design and production it continues to have the best.

Experience has shown that only the best is good enough.

| Totalisator Indicators - Tote Topics number 27 - March 1969 |

Since racing began indicators have been used on racecourses and, in the early days prior to the introduction of the totalisator, indicators were used mainly for the display of horse and jockey information. The requirements then were entirely different because information had to be changed only once each race, whereas a totalisator display is changing throughout the whole of the betting period.

The first totalisator betting system was invented in 1872 by a Frenchman, Monsieur Oller, and it was known then as the Pari-Mutuel. His system was completely manual without any form of indication of the betting trend and even to-day similar manual operations are still in use.

Eight years later, in 1880, the first totalisator indicator was introduced in Christchurch, New Zealand. This was the first mechanism introduced to the Pari-Mutuel System of betting and the equipment included an indicator which was operated by hand and displayed information on the progress of sales of tickets on various horses. The main disadvantage with this system was that it was very slow and was always much behind the actual betting. It was not uncommon to see the horses delayed at the start for 10 minutes or longer to allow all tickets to be displayed on the indicator. This delay presented many problems to the Race Clubs and while many attempts were made to overcome these difficulties it was not until 1912 that Mr. Julius (later Sir George) invented a machine that was the answer to this and many other problems. His machine revolutionised totalisator betting. Not only could it automatically and instantaneously record and display the number of tickets sold on each horse right throughout the progress of betting; it could also aggregate the number of tickets sold. This was the first successful form of indication and was known as the Drum Type Indicator and till about 1930 this form of indication was installed on most of the leading racecourses in Australia, New Zealand, the East and in Europe, notably at Longchamps, Paris.

Contemporary note: regarding the 10 minute delay posting dividends, in the 1980s, well into the computer era, I recall attending a meeting where we discussed a proposed solution to reduce the too often occurring problem of delays being incurred with calculating dividends due to the TAB's transaction processors having to wait for final collations to be received from the multiple on course totalisator systems supplied by different tote companies. Some problems persist!

Displaying the number of tickets or units sold on each horse and the grand total allowed the public to follow the trend of betting, and some alert punters could even calculate the approximate dividend. It was not easy to calculate this dividend, particularly with the first totalisators, because not only was it necessary to take into consideration the Government Tax and Club deduction but the pool had to be divided into three lots, 60% for the winner and 20% for each second and third.

The equipment still did not display the most vital information to the better - how much will I collect if my horse wins? Further research led to the development of the clock dial type indicator and the big breakthrough came in 1927 with the introduction of the automatic odds equipment and the barometer type indicator. For the first time the public could see the expected dividend or odds without having to make any calculations. The final dividend could not be calculated until the betting had stopped but, this is a feature inseparable from the Pari-Mutuel or Totalisator System. In practice this does not cause any real inconvenience because years of experience have shown that, after the betting has settled down, the odds on each horse change very little during the betting period and the final order of popularity becomes obvious very early.

Examples of Clock Dial indicators are visible in the image below. They are the Win and Place grand totals visible at the top of this building. The Clock Face indicator could be used for displaying odds as well.

An example of a barometer style indicator

Webmaster's note:

The Win and Place barometer odds indication for each runner is visible below each runner number 1 to 24 in the image above. Neville Mitchell, the best Automatic Totalisators Limited historian I know, informs me that the indicator shown in the image above was in the paddock at Rosehill Racecourse in Sydney. This building that was the main tote building with the machine room in the upstairs area, no longer exists.Following is an extract from an email Neville Mitchell sent in March 2019, over two decades after this page was first established, which relates to Rosehill Racecourse. In this extract Neville refers to a time in excess of another three decades prior to the existence of this webpage:

Amazing turn out at Rosehill races yesterday largest crowd in 20 years to see the wonder horse Winks win again. Rosehill is a huge enterprise now very much bigger than when I worked there circa 1963 there was several ex Sydney trams converted into tote houses and the main tote machine room with a Barometer indicator was infested with possums.So ends the note.At one the time the oncourse engineers were having problems with the Punch Tape Doubles Recorders I was called in to investigate, The system was powered by alkaline battery's with a charger supplied by the battery’s maker I found that the charger did not fully charge the battery. I redesign the chargers adding a extra 2.4 volts solved the race day problems.

I was also involved with Norman Noble and The Rosehill Members entrance and Railway Station turnstile installation. A strange problem came up that annoyed Norm and the race club management, the 4 Exit turnstiles would slow up when hundreds of people were leaving the track. I was assigned to find the solution back at Meadowbank. The fitters in the turnstile division were given a new oil to be used in the hydraulic Dash Pot that controlled the rotation speed of the tri arms, the oil was the latest thing Viscostatic. At ambient temperatures it was very thin and as the temperature {in Car engines} rose the oil thickened, the theory being that thin oil made for easier engine starting and thickened when warmer, less oil was used by the engine. In the turnstile’s hydraulic Dash Pot, rapid usage caused the oil to thicken thus the slow Tri Arms rotation. Changing the oil back to SAE10 solved the problem.

I went to the races several times with Norm, he knew everyone who came through the Members Owners Trainers & Jockeys Turnstile, often asking for a Hot tip!!

The design of the barometer indicator was such that it could be mechanically or electrically driven from the aggregating equipment. It was usual to have one indicator mechanically coupled to the aggregating equipment and the others electrically coupled by Selsyn control for remote operation. This feature was also possible in the later model drum indicators.

The barometer indicator was installed extensively around the world until about 1950, when the shutter type indicator was introduced. The name of this indicator, unlike its predecessors, does not give a graphic picture of its method of operation. It is, in fact, similar to the printed cloth destination blind used in buses. The shutter refers to a metal plate which is used to cover the aperture and hide the blind during setup and between races. This type of indicator was electrically coupled to the aggregating equipment. It held the field for a comparatively short time until 1955 when the lamp box indicator was introduced.

The indicator at Wentworth Park, shown in the second image above is an example of a lamp box indicator.

During the period when the shutter indicator held sway another type, the projector, was introduced for indoor use. These projected the numbers onto a ground glass screen from a photographically prepared plate. Like the shutter indicator it was superseded by the lamp box.

Webmaster's note:

A Projector Indicator in the Lady Members RandwickThe indicator shown below is an example of a projector indicator mentioned in the above text. This is not part of the Tote Topics article however it is a description by Neville Mitchell of the indicator in the image below:

I dismantled this indicator in 1968 during the construction of the QE2 Grandstand I rescued the two large power transformers which Ron Hood sent to his friends at the Eveleigh Railway Work Shops to be turned into stick welders one for each of us. I also removed some of the projector focusing lenses as they made great magnifying glasses. The indicator was replaced by the 3 1/4 inch 6 x 4 lamp panel indicator that was used to display Win and Place Odds via the AWA/ATL CCTV system.That's the end of the note.Working in the Lady Members on race day, was an experience. You had to be properly dressed reefer jacket, tie Members pass Tag. The overhead projector was very hot. When working each projector lamp was 100 watts. The projector device used the Wheatstone balance principal to rotate the projectors positive glass disc which had the odds printed on them. A set of glass lenses were used to focus the image onto the back of the frosted glass screens at the front of the indicator housing. The devices made a interesting noise as they searched for new odds postings. Some would oscillate between two settings before settling down. The heat from the unit was felt by the girls working the J8 terminals. As the heat built up in the display units the projectors became more erratic in operation, so we would open the back doors to allow some cooling, thus even more heat blew onto the already complaining girls. This was OK until there was a gust of cool wind that would cool down the Resistor fans in the bridge circuit causing a flurry of oscillations. One of the senior technicians told me he would turn off the system and then watch the infield Blind Indicator, noting when there was an odds change then re-enable the projectors to read the same as the Infield then disable the system again. I was afraid of doing this as I had seen some pretty awful scenes involving mink clad ladies when the Odds were wrong at payout time.

The first A.T.L. lamp box indicator was installed at Randall Park, U.S.A., in 1955, and since then lamp boxes have gradually replaced all previous types of indicator. They are flexible, reliable and virtually maintenance free and can be manufactured to display any information such as odds, approximate dividends, results, final dividends, margins, state of track, race time, minutes to race, time of day, signs, photo, etc.

A great deal of research has gone into the design of lamp-boxes and the operating relay set, and indeed the whole lamp box, can be made to plug in for ease of maintenance or portability. A recent design change has been the introduction of a printed circuit card with cradle type relays to replace the conventional telephone type relays.

Lamp Boxes can be made in any size to suit the viewing distance and, as the brilliance of the lamps can be adjusted for the prevailing light conditions, they can truly be described as the most versatile of all the types of indicator available. With this is coupled the high speed of change of information, up to 25 figures a second, which makes them the most suitable and economic display device for use with electronic totalisators.

J.F.P.

So ends the Tote Topics extract. It is signed J.F.P. identifying it as being written by John Pickering who was the Marketing Manager of Automatic Totalisators Limited. The Tote Topics company magazine was one of his responsibilites.

The image below is an example of an ATL Lamp Box indicator. The right hand side of the indicator is not in view, obscured by a pillar. It is at The Gabba Greyhounds in Brisbane. The PDP11 based totalisator, which I worked on the development of and worked on for the lifetime of this system commenced operation here in 1979. This image is particularly interesting as this dog track at the Gabba no longer exists. The track ran around the outside of the Gabba Cricket Ground. This all disappeared as a result of the construction of a new Sporting Stadium complex, a project that began in 1993. The TIMs in operation here were initially all J22s which can be seen in operation at the near windows with their shiny lids, later the number of machines were increased with the addition of J25s and a couple can be seen in the far selling windows with their blue sides. The opening of the ATL computer tote here in 1979 was a big day for me as it was the first live tote operation of a system that I had worked on. I had no first hand experience with tote operations and only had a brief observation of the company's operation at Harold Park.

Neville Mitchell remembers the following about this indicator:

The Indicator is one I did a lot of design work with Phil White. The packaged lamp sockets and the driver board was an idea I had. I found the MBC lamp sockets in a UTILUX Automotive catalogue. I was able to get them to modify a socket with pins that could be directly soldered to a PCB. An extended Bakelite lamp shroud and the 5 watt tail light lamp in the 6X4 matrix, made for a excellent lamp panel digit readout. The coloured Runner Numbers were also my Idea, some of the colours when back lit did not work well especially runner number 7 the black and white.A Lamp Box Indicator in the Main Tote at The GabbaA young recently graduated engineer Tony Park, was working for Phil White on the design of the Gabba Greyhound Track's main tote odds and a running message board. My engineers and draftsmen were designing the 6 x 4 matrix lamp panel and the indicator housing, cabling , power supply. The small group included myself, Ted Kendrick - mechanicals, Alex Chitoff - PCB design, all working to Phil White's and Tony Park's design concept. The final assemblies and initial testing was not at all difficult it all worked very well. There was a minor timing problem and Tony was working on a solution.

One afternoon Phil White came to our office and asked if we had seen Tony, as he had not returned from his usual lunch time jog along the Parramatta River bank. Phil was alarmed as there was an ambulance and police gathered on the road by the river. Shortly police came and asked if anyone was missing. Phil accompanied them back and he was devastated to find Tony deceased from heart failure. A cloud gathered over the ATL staff, women and men in tears, finding it hard to believe that such a nice young man had passed away. It took days to recover and get the Gabba indicator packed and despatched.

In my 32 years at ATL this was the second unexpected death, Peter Rolls and much later Tony Park, both occasions set the company and its people back, taking a long time to fully recover.

In 2011, we were still maintaining an ATL Lamp Box indicator at Eagle Farm racecourse. It was much larger than the one above, displayed a lot more information like up to 24 runner win place odds, dividends and placings for all pools, judges information, race run time information and free format text messages. It was at least twice as high as the Gabba indicator and over four times as long. It was contained in a specially designed building in the infield near the finishing post and clearly visible from the Members and Public stands. Ironically, this indicator is the most photographed part of any totalisator equipment on any of the racetracks that I worked on and yet I do not have a photo of it myself. This is despite my having spent many occasions and a lot of time inside this indicator, involved with identifying the failed component or components, of difficult to isolate faults that it developed. The reason that this indicator is so well photographed and filmed in comparison to the rest of the tote, is that the tote machinery apart from that which is for public display or interaction, is hidden away in computer rooms and this infield is at a location where horses running to the finishing line are filmed and photographed and the resulting video and stills, always showed the indicator in the background. Another interesting thing to note, is that this Eagle Farm indicator over its lifetime, operated with four different generations of totalisator systems. First the ATL PDP11 system, then the ATL VAX tote system, then the AWA DLT tote system and finally the TAB Limited/Tabcorp OCTS system. It had been operating for approximately 30 years in a very hostile environment for electronic equipment. The only significant problem, which was signalling the end of the indicator's life, was the waning source of replacement bulbs for the lamp panels. Following is an image of the Caracas infield indicator, which is a lampbox type and is reminiscent of the Eagle Farm infield indicator. The Eagle Farm infield however was installed about a quarter of a century after the Caracas one.

The Caracas Infield Indicator

In December 2012 I visited my eldest son in Perth. I visited the Cannington Greyhound track as it is mentioned in the Tote Topics chapter of this website. As a result, I met with Graeme Collins who I remembered from the ATL years. We did some serious reminiscing. I learnt that, like us, he was still maintaining an ATL Lamp Box indicator, his at Cannington ours at Eagle Farm. It was interesting to find that, despite the fact that we had not worked for the same organisation for over a quarter of a century, our opinions regarding the industry were so perfectly aligned.

One more observation of ATL Lamp Box indicators. In 2008 I went to Hong Kong for a holiday. Of course I could not resist visiting the racetracks at Happy Valley and Sha Tin. The Hong Kong Jockey club technologists pride themselves on being technological leaders. I recall reading much about their large screen display. At the time it was regarded as the largest television in the world. It is located in the infield and is watched by punters in the stand and on the ground in the outfield. When I saw it I was amazed to find that this large indicator sized television display was right next to their ATL Lamp Box indicator which they had maintained in perfect working condition. The latest and the oldest working well together!

Neville Mitchell recalls the following regarding the Lamp Box Indicators:

When I did the calculations for indicator power transformers, my calculations of the power loading always annoyed the older engineers, as I allowed for an all-lamps-on test at full voltage. They were used to loads of maximum lamps on per numeral/character, which is great for the budget but hell for the maintenance personnel. The Melbourne Metro Racing Clubs was where I found that standing in front of an indicator, while it cycled the lamps, you were supposed to note the dud lamps! This was a great waste of time. My scheme with all lamps on made it easy to detect the duds for repair.I can attest to Neville's observation above. As indicated above, we had one of these lamp box indicators at Eagle Farm. I have personally wasted a lot of time, waiting for diagnostics to cycle through all the lamp boxes in the indicator and it has wasted much more time of my staff who had to work on it over the decades. One observation I will make is that the lamp boxes were great heaters. Even in normal operation, with the required number of lamps illuminated to represent the required alphanumerics on the indicator, they would raise the temperature inside the indicator building well above the ambient temperature and during summer this made the inside of this building uncomfortable to say the least.

Go back to the index

Go back to the index

Go to the bottom of the page

Go to the bottom of the page

On the subject of ATL indicators, following is an interesting description from Neville Mitchell of a novel pup up indicator installation at Randwick Racecourse.

| Randwick Results Indicator by Neville Mitchell |

Automatic Totalisators had the operational contract which dated back to the early days of oncourse totalisators and was invited to offer an upgrade of the facilities, to provide new modern open fronted tote selling lines. The offer was accepted

Included in the upgrade was the first oncourse CCTV system using cameras to display the odds and dividends on multiple television receivers installed in the new stand and other areas. A three inch lamp box, win and place odds indicator for the Lady Members was to be the source for the display. Also in the upgrade was a new infield Results indicator it was to be built in the Flat area of the race track directly in front of the members viewing area. {The Flat was the cheapest entry area for race goers and located on the inside of the racetrack.}

The design of the results indicator was by ATL's executive engineers and oncourse staff with agreement with the AJC. The main concept was devised by ATL executive engineers Don Hardy and Talis Bachmanis, involving a six metre by four metre box housing one metre thick and mounted atop a building with hydraulic rams to raise and lower the structure. This allowed the members to observe the race start from the seven furlong barrier position on the far side of the race track.

My office staff did all the mechanical detail for the housing including glazing and service access. The design of the supporting building was by the AJC's architects. The hydraulics design and construction was by Joseph Lucas Engineering a well established British company.

It fell to me to design all of the electrics for the lamp panel digital and alpha numerical displays, including the Judges and Stewards control Consoles. All the electrics were contained in a standard ATL six foot cubicle. This included all the switching for the hydraulic lifting rams and each of the lamp panels had long flexible connecting leads that moved with the indicator. Each lead terminated in a 104 way connector so that installation time would be reduced.

At this stage ATL was very busy with computer tote installations running at a rate of three a year. When the AJC results indicator designs were complete and production was to start there was no capacity to do the task in house. At that time I was doing contract work at home, employing women to assemble printed circuit boards and general electronic work. I was asked to quote for the assembly and wiring of the AJC control rack, some 200 hours of work. I was awarded the job and as the control rack was too large for my workshop I upgraded the garage lighting and began work each evening until midnight. As I had designed the rack I knew it backwards so it was easy to set the work for the wirers. We completed the rack and I ran a complete inspection and, where possible, live testing of each lamp panel's relay drivers.

With a staff of four, I began the work on the tote upgrade first, while overseeing the CCTV installation. AWA provided the CCTV equipment. The oncourse electricians did the hard wiring of power and co-axial cabling. This work proceeded without too many problems.

Working oncourse with factory provided staff meant a very short working day. We would leave Meadowbank at eight o'clock for the one hour drive to Randwick, start work at nine, knock off for morning tea at ten, then work through to noon, then stop for lunch, at two o'clock afternoon tea, leave Randwick at three thirty and drive back to Meadowbank. So, not a real lot was achieved on each day. Already the bean counters (Accountants) were alarmed at the overrun on track labour costs.

My onsite crew consisted of three women and a man. Wilfred and Janet were a married middle aged couple who migrated to Australia from England. They were good workers except for their dread of anything that crawled, notably cockroaches. Racecourses are a favourite haunt of cockroaches, and it was not too long before Wilfred encountered a large nest hidden behind a Terminal frame cubicle. As he removed the cover the roaches changed sides getting away from the sudden light. They crawled up his arms to the accompaniment of loud screams and much jumping around trying to wipe the beasties off. He would not return to work until he had showered and Janet had rinsed his shirt clean of "The filthy things". Randwick cockroaches were unusual as they were white, maybe this was because they lived in dark cable ducting both above and below ground level.

Another event while we were working on the upgrade of the J8 ticket machine selling line occurred when "Skippy The Bush Kangaroo" TV film crew turned up to shoot a episode named of course "Skippy goes to the races". We watched the production as we were where the "action was". The film producer asked if a scene could be arranged where Skippy bought a betting ticket. I agreed as long as it was done during our lunch break. A J8 machine with one of my staff playing the part of the race day tote ticket seller was set up and we all stood around to look like racegoers while a pair of kangaroo paws on long sticks bought a ticket from a smiling ticket seller. A later scene involved a kangaroo hopping to the finishing post. Several kangaroos were emptied out of Hessian bags and all manner of methods tried all afternoon, to get just one of them to hop rapidly down the track, much to our amusement.

The upgrade of the J8 win and place tote selling lines was completed, the new Lady Members odds indicator installed and the infield results indicator built and ready for the hydraulics and my lamp panel installation. Joseph Lucas's engineers arrived on site and connected the hydraulic rams to the indicator housing completing the work about lunch time. They operated the system and the housing rose to its upright position. Job well done! So it was off to the pub they went, leaving the housing in the raised position. A sudden gust of wind from the easterly direction struck the back of the housing smashing the hinges that held the hydraulic arms allowing the housing to topple forward smashing into the face of the supporting building. Luckily no one was nearby; two utility trucks missed being squashed by inches. This incident started a drawn out row as to who was to blame and who would pay for the damage. Eventually Joseph Lucas admitted responsibility and rectified the faults, and then we could start to install our equipment.

It was late spring and the morning sun would heat the black painted housing to a level where it was not possible to work inside. ATL had not foreseen this, so large Vent Axia fans had to be installed to exhaust the super heated air before my men could get inside and secure the lamp panels and lay the cabling. The cabling to the Judges Tower and the Stewards room was completed and their control consoles were installed. Initial testing was excellent as my pre testing proved that there were no design faults or wiring errors.

After the indicator housing was raised and lowered a few times we noticed that the safety glass glazing was cracking, because the housing was being twisted by the uneven thrust of the rams. The northern ram had a 10 metre flexible hose from the hydraulic pump where the south ram had only 4 metres of flexible hose, thus there was considerable loss of pressure in the longer hose. Joseph Lucas replaced the long hose with high pressure steel pipe leaving the 4 metre flexible hose. Now the housing rose and fell evenly. The broken glass panels were replaced. Not long after I noticed further cracking of the glass panels. Close examination showed that the cracks took the shape of a digit. The heat from the lamp panel lamps was causing the cracking. This was ATL's problem and it was decided to ignore the cracking as the wire mesh embedded in the safety glass would hold the panel and not drop broken glass on the public. However water did seep through the cracked glass windows. Now that the housing was not totally waterproof more modifications had to be made to drain the seepage water. Final testing was carried out and a check of all functions of the indicator was now completed.

As mentioned before, the CCTV system not only displayed the win / place odds, it also showed the race results. This was achieved by situating a TV camera high up in the members grandstand focused on the above indicator. To get a good picture a long focus lens was required. It was critical that the focal distance was measured and the details sent to Bausch & Lomb in London so the CCTV camera lens could be manufactured. To ensure that the measure of focal distance was correct it was done twice by apprentices from the factory. In due course, the lens arrived in time for the impending trial of all the new facilities. I was issued with the lens, carefully enclosed in a special felt lined case and took it to Randwick to check the system. When the system came on line the infield results indicator was very out of focus. There was no adjustment facility provided. A witch hunt began to find who had screwed up the focal length measurements. All concerned said there was no way they had erred. A new measure was ordered. Then the penny dropped. Each of the two measures had been taken using the ATL tool stores, 100 foot tape measure. On inspection it was discovered that the first 10 feet of the tape was missing so it was 10 feet short. Someone had damaged the tape and repaired it by cutting off a 10 foot section and carefully replacing the tape's end clip. An urgent Telex to Bausch and Lomb requested a correction lens to be despatched immediately. In a week we had the correction adaptor and the system then worked very well.

More problems arose. All of the existing tote and power underground cables that went to the now demolished Members stand had been drawn back away from the new works and located in a large concrete pit about three metres square and two metres deep. The carefully coiled cables were secured in the pit by a heavy checker plate cover screwed in place then while the building progressed the area was used as a bulk sand and gravel dump right on top of the pit. When we were ready to re install our cables to a connection frame in the new grand stand the pit site was cleared and the cover removed to reveal no cables! Every one had been severed at its entry point to the pit. We estimated that one ton of copper cables had been stolen, despite all the precautions taken to secure them. It was impossible to rejoin the cables, so new cables were then installed between the paddock's terminal frame and the new grandstand. The police never traced the stolen copper. ATL had to bear the cost of the new cabling, the budgets for the whole project were woefully under estimated anyway!

Tragedy struck the project when one of the race club's contract electricians was fatally injured when a power pole he was working on collapsed. The electrician was a good friend of mine as we had worked together at the Wentworth Park greyhound track. He was a Dutchman who had survived WW2. He was also an accomplished artist delighting in drawing fighter aircraft in battle.

On a Sunday the AJC ran a phantom race meeting with the public allowed free entry. About ten thousand people turned up and all the new systems were being tested. Faults in the grandstand design became apparent with sewage spillages and many faults in the equipment rooms and the kitchens. The results indicator developed a problem that had not appeared during testing, when the judge entered the results and pressed "Display Results", the results would come up in the lamp panels then after a few minutes drop out. This was a real let down for me. On the following Monday we tested and checked every component of the Lights-on circuits with no apparent fault. Then I noticed that all of the lights-on contactors were slow to operate, and when operated were magnetically weak, you could easily pry the armatures apart. I peeled the maker's 50 volt DC label off one of the contactor's coil assemblies revealing the original coil specification as 240 volts AC, thus the weak magnets. The drop out occurred when the power load of the operating track caused a voltage drop to the results indicator. No further electrical problems appeared during the next 7 years of service.

The design of the support building had to be altered. When it rained the indicator housing collected water on its face and when raised to the display position it dumped gallons of the water on the punters who were sheltering under the front of the support building. An awning built across the front solved that problem.

Randwick Results Dividends and Judges Indicator

The above photo shows the results indicator in the old Ledger infield area. At one stage in its long life the indicator was used as the foundation for a podium built for the Pope's visit and the Mass that was held on the racecourse for 90,000 people watching from the grandstands and grassed areas in front of the podium..

The then ATL oncourse race day Deputy Manager was Ross Jenkinson, a very staid gentleman who insisted that I attend. At this time we were having extensions done to our home so at least the extra money came in handy. The drawback was the loss of family time especially on Saturdays and public holidays. Easter time was usually an intensive racing period. I did manage to get to the Royal Easter Show with the family, but only late on a Saturday afternoon after the last race at Randwick.

During this time I had opportunity to watch the Julius Totalisator system in operation. There was never a breakdown or anything that needed engineering intervention. Usually two senior engineers were on duty in the Totalisator room. Apart from checking the race day input settings they had an easy time. The very rare adder faults were attended to immediately or after the last race so I did not get to learn very much about how to handle emergency situations.

Observing the tote selling lines was also a learning curve, I got to know the faults that occurred in the J8 ticket machines and the strict procedures used to make on line repairs without causing any stray bets to occur. And of course deal with the sellers to ensure there was no discrepancy in the tickets sold counters.

I returned to the Drawing office as Assistant Chief Draftsman and then Design Office manager. I was often called on to travel to overseas tracks to do initial surveys and later I went to the USA to assist in the design of the J22 terminals fibre optic bar code scanning device. Lastly I accompanied the sales engineers to Hong Kong prior to the awarding of the new Shatin Race Track's computer system, and that is another story.

Randwick Judges and Stewards Consoles

The above photo shows the Judges & Stewards consoles. There was also a stewards console in the Stewards Room so result changes, Protest, Dismissed, Upheld ,Weight etc., signage could be declared. I spent some time up in the judges box over a one year period as I was required to attend Randwick meetings, just in case anything went wrong - never did though. They were interesting people and I was amazed at their methods of remembering horses and jockeys. Some judges called the race under their breath.

After long service, some time after AWA won the AJC contract and the flip vane infield indicator was installed, the Results Indicator was dismantled and sent to SA where it is installed at Morphettville race track in Adelaide.

So ends the Randwick Results Indicator segment.

I must give a credit here: Thanks to Chris Robertson for having pointed out a second evasive error on this website, the first being the location of Blue Bonnets Racetrack in Canada. The original year, erroneously specified for the construction of the Queen Elizabeth stand at Randwick, under the subheading The saga of an interesting construction above was 1978, which now correctly reads 1968. Many proof readings by multiple people took place prior to this section being placed on the Internet. Despite the fact that the year specified was a decade too late, it evaded detection. Chris is the most informed punter I have had the pleasure to know and has more knowledge of ATL's product line and its deployment around the planet than most who worked for the company. He has perceptions of tote operations that gives the impression that he spent many years as a tote manager rather than a punter. I mention this as I consider Chris an outstanding source of pertinent information relating to the subject of this website and I find it impressive that these corrections come from someone outside of the company Automatic Totalisators Limited and not from someone who was within. Thanks again Chris, keep up the good work!

As Neville has mentioned AWA winning the AJC contract above, I think it is pertinent to present Chris' observation of this takeover:

In April 1977 I attended a race meeting at Randwick to experience the unique opportunity to bet with three different tote companies at the one racecourse on the one day. Universal Totalisators operated the Extra Double, the Daily Double and Quinella pools on Sydney races; ATL operated all other pools on Sydney races; and AWA ran the interstate tote pools (on Melbourne and Brisbane). The AWA tote was phased in so as to identify issues before it took over sole totalisator operation of all pools on all meetings. Obviously a few kinks slipped through this phasing in period because there were some major breakdowns when they took over full operation. ATL officials could be forgiven if they felt any schadenfreude at AWA's expense, although they probably had too much dignity to do so.

As the events in this segment took place in 1968 I have included one more memory from Neville Mitchell, relating to that year:

1968 was an eventful year for me, I was being promoted on all fronts. Sandy Richardson was luring me to go to South Africa. I decided not to go. I was still involved with the MMRC Melbourne project and meanwhile worked as a detail draftsman in between doing a 5 day a week project at Randwick. Then if I was still awake I worked on Saturday afternoon as a "mechanic" at the races. Sandy Richardson was successful in getting Keith Tomlinson, my work mate, to go to Johannesburg. Keith worked there for many years. I've lost touch with Keith. He was British born raised in NZ, trained with PMG and at an early age was a "Super Tech" on crossbar exchanges before joining ATL. Working together we were nicknamed Abbot & Costello as Keith was tall and well built and I was short and skinny!For those not familiar with engineering, a Super Tech is a contraction of Supervising Technician.

| Backing Organisation |

Automatic Totalisators Limited is responsible for the efficient performance of the hundreds of Totalisator Systems it has installed at racing venues around the world. Because of the Totalisator Systems each Club using them can in the future, as in the past, bank on continued efficient and uninterrupted betting operations. This is not only because of good design. It is also because of the smooth and instantaneous after-sales service and maintenance which the Company offers along with its product. A.T.L recognises its responsibility to see there is no hold up to the multi-billion dollar world racing industry its systems serve. It ensures having spares and spare parts available to every Club using its equipment. Those parts and specialist Totalisator Engineers are available immediately when and where required.

Components for all A.T.L installations are held at the Company's Research and Main Manufacturing Division at its Sydney headquarters where the plans of over 200 local and overseas Totalisator Systems are held and can be used to pinpoint a technical problem anywhere in a system, anywhere in the world.

There is another unique after sales service offered by A.T.L. It trains Totalisator management and , in many places, A.T.L staff handle the entire race-day Totalisator operation.

A.T.L service and maintenance experts have learnt a lot by operating their own equipment. In so doing the Company's policy is reflected: "It is only good enough for our customers if it's good enough for us to use ourselves."

A.T.L's staff involvement with racecourse Totalisator operations has also stood it in good stead in keeping pace with pari-mutuel betting trends.

The skilled technology and in depth A.T.L research are behind every one of its many installations. They have kept services and maintenance to a remarkable minimum.

One of the most graphic examples of this is the 46 year old A.T.L Totalisator System at the French Longchamps Racecourse...still going strong and never one serious mechanical interruption on a race-day.

| Ticket Issuing Machines |

This is an extract from a company booklet titled The Computer Tote

Automatic Totalisators Limited is an international pioneer in the design and production of ticket issuing machines for betting systems of every kind.

Since the Copany gave the world its first Totalisators, it has developed over 100 types and models of ticket issuing machines.

Some old ATL Ticket Issuing Machines

Above is an image from The Computer Tote booklet, which illustrates a small sample of the over 100 types and models mentioned above. These represent the era when the computer tote has been established and the first TIM in the image, the J8 is rooted in the electromechanical era whilst the following machines are transitioning to predominantly electronic machines. The image also shows the tickets produced by each model except in the case of the last one in the image, the J20 where the mark sense card it uses is shown.

Today there are over 15,000 A.T.L designed ticket issuing machines in use throughout the world's racecourses, paceways racetracks and jaialai frontons. And practically every ticket issuing machine made by A.T.L is still in service. Their service record highlights the two main characteristics of the A.T.L ticket issuing machine - reliability and efficiency. Automatic Totalisators Limited firstly developed for use with computer totalisators, the J11 ticket issuing machine and, since then, the J17, the J18 and the J20. The latest styles incorporating up to the minute electronic techniques, like their predecessors, maintain the company tradition of reliability and accuracy.

The versatility of A.T.L's ticket issuing machines is underlined by the fact that those currently in use with an electromechanical system can be integrated into a computer Totalisator System without modification.

Research, meticulous care in design and long experience are not the only qualities behind the A.T.L ticket issuing machine. Another is thorough product-testing. Every ticket issuing machine undergoes an exhaustive test for operational reliability and is then tested in the field by A.T.L staff.

The reliability of A.T.L's ticket issuing machines is enhanced by the overall security of the Company's ticket issuing system which protects against forgery. A.T.L supplies ticket paper to race clubs throughout the world which use its equipment. A.T.L's ingenious pattern of ticket markings and the use of special inks for printing ticket backgrounds protect the Totalisator System against the counterfeiter.

A.T.L has over five decades of experience behind it in providing complete security for the multi-billion dollar turnover of its customer clubs.

I am pleased to inform you that your company's Wagering Terminal J33 and Mark Sense reader J40 have been granted an Australian Design Award.

Your Australian Design Award Certificate is being prepared. If you so desire, Mr Molnar will be pleased to arrange a public presentation of this certificate to your company.

Congratulations on these fine products. I hope that Council's recognition of their high standard will prove beneficial to your company.

Note: Wagering Terminal is a later term for Ticket Issuing Machine that was introduced to specify the type of machine from the plethora of other ticket issuing machines that came on the market after the advent of the electronic era.

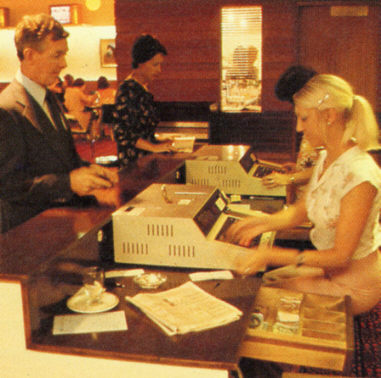

| ATL Sell/Pay system - Tote Topics Summer 76/77 |

I have included this article as it relates one of the many terminals designed and manufactured by ATL. I have selected the J22 as it is the first ATL terminal I worked with after joining the company. As Chief Engineer of the Brisbane Branch the most challenging objective was keeping the transaction processors functional and this demanded the most time. I had staff who did the J22 maintenance and I helped them with the more difficult problems. My association with the J22 lasted almost a decade. Our customers in Brisbane later purchased more terminals which were J25s and J36s. After AWA took over ATL we used TIM91 terminals and when TAB Limited took over we used PCTims.

Development work on new products was increased during the year resulting in the release of a ticket issuing machine known as the J22, which incorporates some new and advanced technology. This terminal has created considerable interest amongst racing clubs, being more flexible than competitive products, and designed to achieve significant labour savings in the operation of the totalisator. Development work is continuing at a high priority on other advanced terminals for both on track and off track use as well as low cost computer systems to cater for the needs of smaller racing clubs.

The J22 terminal was the major reason for our success in winning the highly competitive contract with the Royal Hong Kong Jockey Club for a computerised totalisator system, which will be installed at their new Shatin race-track. This system will be the most advanced in the world, and will incorporate many innovative ideas for admission and crowd control, cash management, display boards, and other business information for racecourse operations. A central complex of computers are included in the contract together with the ticket issuing machines, turnstiles, display boards etc.

The A.T.L. Model J22 Sell/Pay Terminal is a high performance transaction terminal designed to meet the demanding criteria essential to an on-course totalisator incorporating the flexibility required by modern operations.

The J22 is capable of selling and paying simultaneously on all pools and values operating at the course. It is this feature which allows a comprehensive totalisator service to be provided throughout the course either by single terminals, operating in restricted areas such as bars and restaurants or by terminals dedicated to specific functions in the main public betting areas.

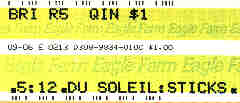

Reproductions of J22 type tickets are shown on the opposite page. A separate ticket is issued for each pool however this ticket may be of any value and can accommodate up to six runner selections. Further a single ticket is available for an 'each way' bet. A ticket may therefore accommodate equal investments on up to six runners for Win, Place and Each-Way or up to six runner selections for the combination pools, i.e. Quinella, Forecast, Double, Trio or Trifecta. There is no restriction in the number of selections in each leg of the combination pool providing the total does not exceed six. For example, a typical doubles ticket may have 6 & 9 selected in the first leg and 1,8,10 &14 selected in the second leg, which is a total of 8 combinations in the same ticket.

The major components of the J22 are:

Printer

Reader

Keyboard

Operator Display

Customer Display

The Printer is a 7 x 5 dot matrix printer which simultaneously prints 2 lines of 9 mm characters, 1 line of 3mm characters and 2 lines of bar code. The time required to print and issue a ticket is less than 0.4 seconds.

A ticket printed on a J22 Terminal

Note: The bar code printed on the ticket had no checksum or CRC. The way errors in reading the ticket were detected was by the use of two bar codes written on each side of the ticket. One bar code is the one's complement of the other. During a read operation the bar code on one side is complemented and the result compared with the bar code read from the other side and if they do not match an error has occurred.

The Reader automatically reads the serial number and date recorded in bar code on the two edges of the ticket. A Ticket presented for payment is fed into the reader slot where it is read, the information is transmitted to the computer system and if a dividend is payable the ticket is mutilated by two punches and returned to the operator and the amount payable is displayed to both the operator and the customer. If for any reason the reader is unable to read the code, the serial number, which is also printed on the ticket in alpha numeric characters may be manually entered by the operator.

The Keyboard is conveniently arranged to encourage operator speed and provides a discreet button for each function. Thus avoiding the possibility of mistakes in entering coded information.

The Operator Display consists of 32 alpha numeric characters to display all information as it is entered through the keyboard. The operator may visually check the details of the transaction before it is transmitted to the computer system. Further information such as customer total and amounts payable are also automatically displayed to the operator.

A Cumulative Total for each series of customer transactions is automatically calculated and displayed to both the customer and the operator. The total is cleared before commencing with a new customer, then the value of each ticket sold is added and amounts payable are subtracted from the cumulative total.

The J22 incorporates the speed and reliability of the earlier ATL Ticket issuing Machines together with the all purpose capability necessary to the modern on-course totalisator operation.

While the J22 is capable of selling and paying on all pools simultaneously, certain terminals would be dedicated to specific pools and value to provide fast service windows in the larger betting areas. These terminals would be programme dedicated to reduce the amount of information entered for each transaction.

To sell a ticket the operator first clears the customer total then enters, the value, the pool and then the runner selections. The information may then be visually checked on the display and if correct it is then transmitted to the central computer. If it is incorrect the operator can clear the entry.

The central computer on receiving the details of the bet will check that no errors have occurred in transmission and then check that the bet is valid e.g. that the pools is operating, that betting is 'on', that the selected runners are not scratched. If the bet is invalid the computer will transmit a message to the terminal which is then displayed to the operator.

If the bet is valid the computer will assign it a unique serial number and record the details in core memory for odds and dividend calculation, on disc memory for payout, and on the daily history tape as a permanent record. The terminal cash status record is also updated. This full record of every bet is kept by both computers.

When the bet is recorded the information is then transmitted to the terminal together with the serial number and the ticket is printed. The details printed on the ticket are theretofore identical to those recorded by the central computer. The value of the ticket is added to the customer total on both the operator and customer displays.

A ticket presented for payment is inserted into the reader slot by the operator where it is then transported through the reader and the bar code on the edge of the ticket, containing the serial number and date is read and the information is transmitted to the central computer.

The computer checks that no errors have occurred in transmission and then locates the serial number on its disc files. The full details of the bet recorded with the serial number are then checked and the computer determines whether a dividend is payable, and the amount, if a dividend is due the computer records that it is paid and updates the terminal cash status file. Further, the terminal cash status is compared with the amount payable to ensure that the operator has the cash to make the payment.

The dividend is then transmitted to the terminal where it is displayed to the operator, and is subtracted from the customer total. The ticket is cancelled by mutilating the bar code with two holes and the ticket is returned to the operator. If the operator does not have the cash to pay the dividend, the nearest cashier is automatically notified so that the cash can be quickly provided.

If the reader is unable to read the ticket the operator may then manually key in the serial number to initiate the transaction.

| ATL Research |

When electronic data processing was in its infancy back in the early 1950s, ATL was researching ways and means of bringing electronics into its totalizator systems. ATL anticipated the day of the computerised, fully electronic totalizator System years ahead of any other Company and its planning engineers intensified their research in the dynamic new field of automatic data processing. When the racing world decided to use the computer for racecourse operations, ATL was ready. The most spectacular evidence of depth of ATL research is that it was called upon to design its very first Electronic totalizator System not for one average size racecourse - which would have been in itself a challenge - but for a circuit of three racecourses with the biggest combined totalizator turnover in the world ... Aqueduct, Saratoga and Belmont Park which are controlled by the New York Racing Association. An enormous amount of research and planning, long before being invited to submit its Electronic totalizator proposal to New York Racing Association, enabled ATL to take on this massive task and complete it so successfully. ATL Research never stops. Having now attained what some years ago would have been regarded as impossible levels of accuracy, reliability and operational speed, ATL research engineers are constantly searching the world market for the latest electronic equipment, improving methods of design and manufacture whether the equipment be electro-mechanical, partially or fully electronic.

ATL's equipment testing program is incredibly painstaking. A newly- designed ticket issuing machine, for example, will issue a million consecutive tickets without one fault as a minimum requirement of its accuracy and durability.

ATL designed and manufactured the first Electronic Odds Computer, the first Electro-mechanical " Totemobile", the first Mobile Computer Unit for Electronic totalizator operation and the first Electronic Ticket Issuing Machine. Intensive research enabled the Company to give the racing world these innovations.

By no means the least important facet of ATL research is that which it carries out on a racecourse where its equipment is to be installed. If there is one thing unique about ATL's approach it is that every one of its totalizator installations has been specially designed for the racecourse it serves.

ATL makes a complete survey of the layout of each race course prior to the signing of the contract and its planning engineers take every aspect into consideration - the location of selling and payout windows, indicator boards, intercom systems and the totalizator Control Room Complex- so that the racing public will be served speedily, efficiently and reliably.

Over half a century of research and experience is built into every piece of equipment ATL supplies to racing clubs around the world.

| ATL Notes on the company |

From small beginnings over 60 years ago Automatic Totalisators Ltd now produce the most sophisticated equipment for the control of betting on racecourses throughout the world, trotting tracks and greyhound events not to mention such events as lotteries, jai-alai and the numbers game.

Today our factories in Australia are manufacturing products that are unique from computer operated totalisators, hardware componentry and software for the typesetting, printing and newspaper industries to nurses call and communication devices to number plates and pressed metal signs.

Our tool-room is one of the best equipped factories capable of the finest procedures and qualified as a testing body for standards and performance in the most demanding industries.

Around the world there are over 60 race courses that are served by ATL Computer Tote Systems and the Mobile Computer Tote is operating at racecourses, paceways and racetracks in Australia and overseas.

ATL's years of experience in pioneering and innovation have allowed it to maintain its leadership throughout the world in the supply of equipment for betting, turnstiles, ticket printing and production and the failsafe design of procedures for the principal clubs in the world's leading cities.

One has only to take a look at the lamp-box computer controlled indicator boards which show up to the second odds results and dividends to realise the efficiency of resulting research by ATL.

Ticket issuing machines have been pioneered by ATL and are capable of handling all betting systems of every kind.