This page contains a photograph which is one of several belonging to the photo gallery pages which are part of several pages relating to the invention of the world's first automatic totalizator in 1913 and Automatic Totalisators Limited, the company founded by the inventor George Julius to develop, manufacture and export these systems.

Copyright © 1998 Email - totehis@hotmail.com

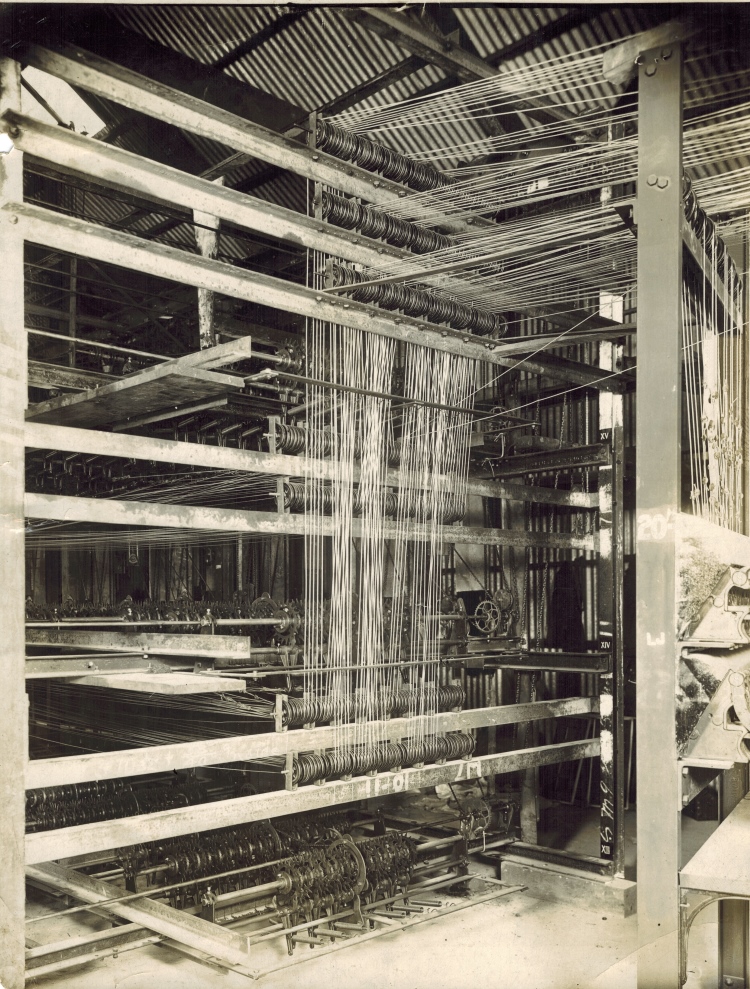

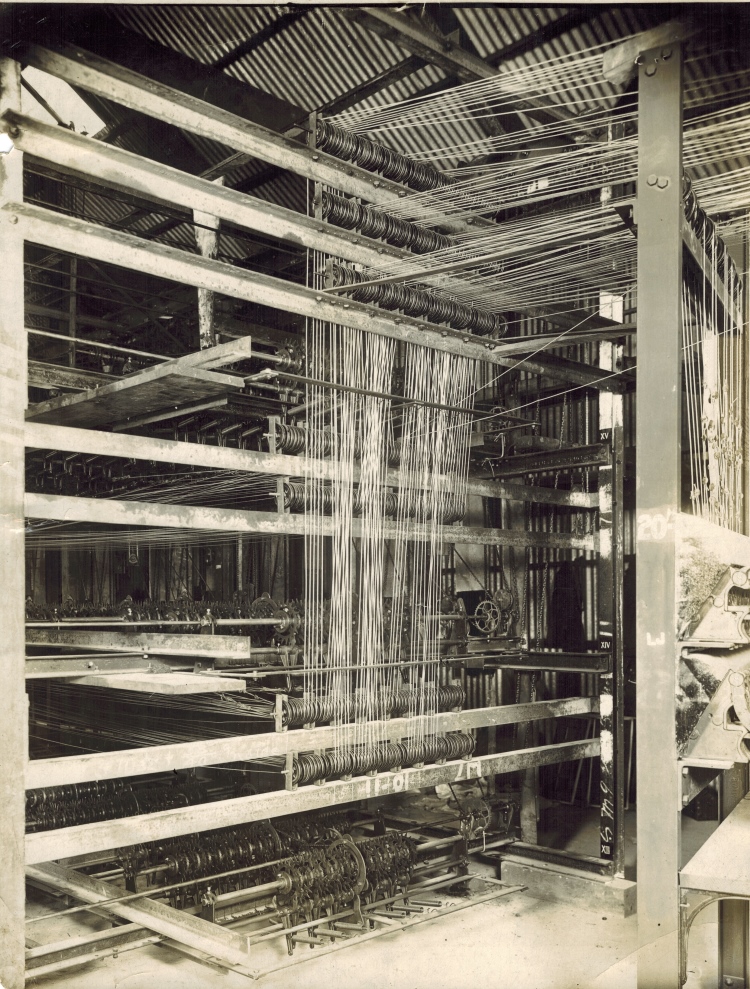

Wiring of the World's First Online Real-time Multi-user System and Automatic Totalisator

This is an image of some of the wiring of the world's first automatic Totalisator being assembled in the factory. This system was later installed at Ellerslie racecourse in Auckland New Zealand in 1913. This system is also significant from a history of computing perspective as it is the first online real-time multi-user system. The installation at Ellerslie was the first automatic totalizator in the world and although it looked like a giant tangle of piano wires, pulleys and cast iron boxes and many racing officials predicted that it would not work, it was a great success.

More after the image...

Click on the image to go back to the Photo Gallery

If you arrived from navigating the website, use the navigation bar at the bottom of this page.

This photograph is over a century old and was 100 years old in 2016--an online real time multi user computing system over a century ago!

The back of the photograph shown in the image above only has two things written on it M1 and Early Purely Mechanical Tote. As this does not identify which installation the equipment in this image relates to, some deduction is required to determine this. The photo M1 is part of a group of photos M1 through M6, four of which have an Auckland Photographers stamp indicating they are of the Ellerslie Julius Tote which suggests M1 also shows the Ellerslie system. Proof positive that this is the Ellerslie system lies in the fact that the Ellerslie system was the only Julius tote that had Ticket Issuing Machines (TIMs), which were fixed and hard wired to the totalisator mainframe machinery. All following TIMs were self contained and transportable. A small section of one of these TIMs, or Selling stations, can be seen on the far right hand side of the image above. On the right hand edge of the image is a pillar, with 20/- and 3 written on it, which has two similar looking bracket like attachments to its right hand side. These bracket like attachments are the left hand end of one of those selling stations which were only used at Ellerslie. Cables can be seen rising up from the selling station over rollers at the top and into the mainframe which is part of the hard wiring I mentioned.

Note the cogs and shafts on the trays of equipment on the left hand side of the image above, inside the mainframe. This is the aggregating machinery. The aggregating equipment consists of shaft adders which have escapement wheels that look like bicycle sprockets which are activated by escapement mechanisms. The wiring in the image above connects the escapement mechanisms to the the beer tap levers, used for runner selection in the selling stations. A few of the many springs in this installation can be seen attached to the right hand end part of the frame of the bottom level equipment near the ground. These springs are attached to the escapement mechanisms and return the escapement lever to its starting position, once it has been activated by a cable from its associated lever in one of the selling booths and allowed the escapement wheel to rotate a tooth.

The image above certainly completes the picture regarding the miles of flexible wire cables mentioned in the following Automatic Totalisators Limited document extract despite the fact that it was taken in the factory and is not yet complete. This can be seen by the many cable rollers on the change of direction shafts without cables. It is possible that the whole machine was not assembled in the factory, just sufficient to demonstrate and prove that the design worked:

These early automatic totalizators were completely mechanical and consisted of Ticket Issuing Machines coupled to Drum Indicator Adder Units, all housed in the one building for one pool only. Miles of flexible wire cables connected the Ticket Issuing Machines to the Indicator/Adder Units. A considerable length of bicycle chain ran over sprockets and heavy cast iron weights were used for drive power.

The wire in the image above is part of the miles of flexible wire cables connecting the Ticket Issuing Machines to the Indicator/Adder Units mentioned. These Indicator/Adder Units are best seen in the above image inside the mainframe near floor level. The drum counter wheel displays which are driven by the Indicator/Adder Units are not visible in the image above as they are off the left hand end of the photograph, they can be seen however in the image below. The man standing in that image has his right hand close to one of the drum indicators which reads 0070. Each drum consists of four counter wheels allowing display of investment up to 9,999 units.

Ticket Issuing Machines (TIMs) are mentioned in the company document extract above. This is a term applied to all of the self contained transportable point of sale terminals attached to Julius Totes after this installation starting with the following installation at Gloucester Park in Perth. The Ellerslie system had TIMs which were fixed and hard wired becoming an integral part of the system so I have called them selling stations to distinguish between the two. Selling Booths are often mentioned in descriptions of the time.

The image above is looking at the right hand end of the totalisator mainframe shown in the image below. A corner of the mainframe is at the post seen running up the left hand edge of the image above. That is the same post as the one on the right hand near side corner of the mainframe in the image below. There are three groups of horizontal beams attached to the left hand post in the image above which are attached at the opposite end to another mainframe corner post on the right hand side of the image, near the corrugated iron wall. This is the right hand rear corner of the frame in the image below. The lowest group of beams in the image above has two beams as does the next group up and the top group consists of three beams.

Back to the Indicator/Adder Units which were identified as being easiest seen in the above image inside the mainframe near floor level. The shaft adders consist of equipment mounted on shafts which are parallel to the beams in the frame. There is a pair of these shafts for every runner in a race. This bottom level equipment caters for ten runners and the equipment continues deeper into the mainframe off the left hand end of the photograph. The width of the mainframe can be seen in the image below. As there is a maximum of thirty runners in a race there are two more layers of similar equipment above the ground layer. The next layer of equipment can be seen between the first pair of beams and the second pair of beams from the bottom in the image above. The third layer is not so easy to see but it starts between the second pair of beams and the top group of three beams. The side of the mainframe that is parallel to the corrugated iron back wall in the image above, is the rear of the mainframe where some of the concrete blocks which are motivating weights suspended on chains can be seen. The corrugated iron back wall mentioned is the same wall that can be seen through the mainframe in the image below. The concrete block weights can also be seen through the frame in the image below, however they blend in with the rear wall and are easier to see when zoomed in. The three layers of equipment can clearly be seen in the image below identified by the three rows of drum display counter wheels with the aggregating and display drive equipment behind them.

Ellerslie mainframe in factory

Thanks to Tony Shellshear, George Julius' great grandson, for providing me with a mass of images and documents related to George and totalisator history to which the above image belongs.

The image above shows the Ellerslie totalisator mainframe in the factory and gives an idea of the size of the machine. When the system was installed inside the Ellerslie tote house it was on the first floor as can be seen in the two images below. At Ellerslie the thirty selling stations exist underneath this mainframe and extend out on the ground floor level with twelve selling stations to the left of the frame and another twelve selling stations to the right of the frame. This can clearly be seen in the image below titled The Ellerslie tote house. The mainframe in the image above is inside the central high section of the tote house in the image below, sitting above the selling windows below with three of their shutters open. This central part of the tote house has an indicator board. The three rows of ten drum display counter wheels seen in the mainframe image above, sit behind the three rows of ten slot like windows seen in the central section of the image below. Also in the image below, under the apex of the roof in the central section, above the main section of runner totals, is the Grand Total drum display which can be seen at the very top centre of the mainframe in the image above. The selling booths with six large open shutters on both sides of the central part of the tote house in the image below, each house two selling stations.

Three of the selling stations can be made out at the bottom centre of the image below titled Tote mainframe after installation at Ellerslie, to the right and below the right hand corner of the landing. The selling stations had beer tap like handles and a few of these handles can be made out in the image mentioned. Looking carefully, the ends of them can be seen extending from the far side of the right hand two selling stations up and to the left in the direction of the top left corner of the image below titled Tote mainframe after installation at Ellerslie. Three handles from the middle selling station are visible and four from the right hand selling station is all that is visible of that selling station. Only the knob at the end of the handle can be seen of the right hand most handles in both stations with the rest of the thirty handles in both stations being hidden by panelling. The three selling stations just described are below the central section of the tote house in the image below titled The Ellerslie tote house.

Go back to the index

Go back to the index

Go to the bottom of the page

Go to the bottom of the page

As the totalisator mainframe above seemed to have random numbers on the first two rows it looked like the system was being tested. It is not possible to ascertain what the runner investment counters should read from this photograph however the Grand Total counter at the top of the frame should be the sum of all the individual runner counters below. The bottom row counters are all zero. The first row counters read 291 448 239 155 158 1357 1207 2129 1189 1008 and the second row counters read 102 13 38 67 70 56 13 73 4 257. Adding them all up we get 8874 as shown on the Grand Total counter confirming that this part of the system is working.

It is interesting that the man in the image above is holding a rather ornate looking wheel in his left hand which probably has some significance. It looks like the wheels that are on the shafts running through the display drums. There is one on the shaft running through the display drum indicating 0070 above his right hand. Similarly, in vertical alignment with the one by his hand, the level above has one on the shaft running through the display drum indicating 158 and the level below has one on the shaft running through the display drum below the other two. They are not the wheels in the vicinity behind the display drums which appear circular but the wheels on the shafts which presents an end on view making them appear as straight lines perpendicular to the shafts. I can perceive you asking the inevitable question how do you know what those wheels look like from an end view? A very good question! The camera lens is producing a fish eye effect so as we move away from the centre of the image you get more of a side on view of everything where you see more and more of these wheels as you look further towards the edges of the image. I do not know what the purpose of these wheels are, perhaps some sort of adjuster wheel. On the bottom row of drum displays these wheels are the clearest. They exist between every pair of drum displays. Next to each of these wheels there is a drive chain descending from above that connects to the shaft that the wheels are attached to.

Something caught my attention whilst zooming in to examine parts of the image above more closely. On the beam supporting the top layer of equipment under the drum display in the column to the left of the man standing displaying the number 0158, there is a drawing of what I would call a very sleek sports car. I presume this is someone's doodling, possibly a statement that the Julius tote is a fast machine. It is an interesting modern streamline shape considering this is the era of the Austin 10 and the T Model Ford. It seems to have been done in chalk. The wheels of the car are bolts in the beam that have been left free of chalk.

The two photographs above raise an interesting question. As can be seen they were taken in quite a substantial building. This is not an Automatic Totalisators Limited factory building as that company was only founded by George Julius in 1917, four years after the Ellerslie system was installed. The company that preceded Automatic Totalisators Limited was Totalling Mechanisms Limited. The first factory of Automatic Totalisators Limited was in Alice Street Newtown in Sydney. The building housing the Ellerslie system as shown in the two images above seem to be in a better condition than the Newtown factory although they were both corrugated iron constructions. There is very little written indeed, that I have come across in the documentation of Automatic Totalisators Limited, about the Totalling Mechanisms Limited era and no one I know from Automatic Totalisators Limited who I have asked, even knew about Totalling Mechanisms Limited. However the little that exists does tell us that most work prior to Automatic Totalisators Limited was done at George Julius' residence or a local garage. The building in the first two images in this page do not look like a 1912/13 suburban garage to me! I have referred to these photos as being taken in the factory, however one thing that strikes me is that in the widest view inside this building I have seen, shown in the image above titled Ellerslie mainframe in factory, there is no sign of any plant, of which there must have been a significant amount to construct the parts for this totalisator.

There is a chapter in this website on the Alice street Newtown facotory. To view this select the Go to the index button in the navigation bar at the bottom of this page, then select The first factory Alice St Newtown chapter in the Thirdly section of the index.

The only lead I have regarding early manufacturing comes from a document I saw on the Internet near the end of the last millennium which relates to Frederick Wilkinson. The earliest prominent manager of Automatic Totalisators Limited was Frederick Augustus Wilkinson. George Julius and he designed an electromechanical ticket issuing machine together, to be used with Julius tote systems. Frederick worked for Automatic Totalisators Limited for three decades and became the State Tote Manager. He worked closely with George and travelled widely for the company. Rudolph Wilkinson, Frederick's son, wrote the following:

Frederick Wilkinson was a salesman with the National Cash Register Company and suggested that he and George Julius could make a Ticket Issuer especially for the Automatic Totalisator. FW and GJ worked every weekend at GJ's home at Darling Point on this and invented the Premier Ticket Issuer.

Eventually, the workshop was in Willmont Street, Sydney at the back of the Liverpool Police Station, Liverpool Street, Sydney.

I am not sure of the chronology of this information. As George and Frederick are working on an electromechanical ticket issuing machine this seems to postdate the purely mechanical Julius totalisators, of which Ellerslie was the first. On the other hand this workshop seems to follow the work done at George Julius' home so that might be where the Ellerslie system was manufactured. I have never heard or read anything else about this workshop in Wilmont Street and consequently have nothing more to add.

Full sized versions of the two images below are in the Photo Gallery of this website. To view them, click on the image at the top of this page and scroll up to and select the first thumbnail in the photo gallery index to view the second image below or the second thumbnail to view the image below.

The Ellerslie tote house

There is a small part of one of the selling stations visible in the image photographed in the factory at the top of this page. There is a pillar visible near the right hand edge of the image which has a shelf on its right hand side near the bottom. Above this shelf can be seen the left hand end of a selling station. There are two mounting brackets one above the other which contain the fulcrums for the leftmost upper and lower beer tap like handles of the selling station which has a total of thirty handles, one for each possible runner in a race. As this image shows the frame in the factory and the frame is sitting on the ground temporary selling stations have been set up on the same level to the left and right of the mainframe. Cables can be seen descending to the activating levers associated with the handles in this dummy selling station. In a high resolution version of this image it appears that there are only fifteen cables descending to the handles in this image. As the handles are arranged in two rows of fifteen perhaps only one row has been wired. Either the assembly in the factory is not complete or full assembly was not required to perform the necessary testing keeping in mind that the system has to be disassembled for transportation to Ellerslie. This view of the cabling to the beer tap handles is a good view of the Ticket Issuing Machines coupled to Drum Indicator Adder Units mentioned in the company document extract, below the image at the top of this page. The wires run up from the selling station, around the change of direction pulleys towards the mainframe then around another set of change of direction pulleys and head down to even more change of direction pulleys where they head into the mainframe for connection to the Drum Indicator Adder Units. There is an image of the selling stations in the Photo Gallery of this website. To view this click on the image at the top of this page and scroll up and select the thumbnail of the image prior to the one for the image at the top of this page.

Tote mainframe after installation at Ellerslie

Comparing the image above of the Julius Tote mainframe installed at Ellerslie with the two images at the top of this page which are from photographs taken of the same system in the factory, there is a lot more wiring particularly inside the mainframe in this image than is visible in the images of this system being assembled in the factory. Additionally, it is quite clear that the mainframe image above is not in the same building as where it is shown in the two images at the top of this page. The walls in the image above inside the Ellerslie tote house are wood and in the two images at the top of the page the walls inside the factory are corrugated iron.

The photo that is shown in the image above was taken from the left hand rear of the Ellerslie mainframe and the image at the top of this page was taken from the right hand front. Consequently, you can see some of the concrete block weights on the rear side of the frame near the corrugated iron wall in the image at the top of the page and those weights can be seen at the rear of the frame which we are facing in the image above.

I have been interested in Henry Setright's time as Works Manager of the ATL (Automatic Totalisators Limited) factory at Alice Street Newtown in Sydney and his relationship with George Julius. I knew that Henry was involved in Ticket Issuing Machine (TIM) design. I thought he had designed a TIM that operated with the Julius Totalisator. Ian Waugh, an ex Automatic Totalisators Limited engineer in New Zealand informed me that a Setright TIM was used in New Zealand however he designed it after he left Automatic Totalisators Limited and moved to the UK where he became famous for his bus and tram ticket machines. As the following information provided by Ian relates to New Zealand, it seems to be appropriate to present it here as this page relates to the first automatic totalisator and Ellerslie in New Zealand and Ian's information provides some later history of the totalisator there.

Before beginning, I will mention that I have a minor connection with Henry. I have a letter of commendation from Automatic Totalisators Limited that my wife's auntie gave me. It was given to her father when he left the company in 1921. I worked for the company starting in 1977 which is why I found the letter interesting. The head office address is 10 Castlereagh Street Sydney and the factory address is Alice Street Newtown and it was signed by the Works Manager. The works manager's surname was clear, Setright. The initial of the signature was not so clear and looked like it could be two or three superimposed letters in an ornate fashion, however one of the letters could well be a H. I have seen other evidence since that Henry Setright was the works manager for Automatic Totalisators Limited.

Following is Ian's clarification regarding the Setright TIMs in New Zealand:

Hello Brian, You seem to have an incorrect understanding of the Setright TIM and where it fitted into NZ Totalisator operations. So the following is as I understand it.

A company called Taranaki Electric Totalisators was registered in 1954 to operate at New Plymouth, Stratford, Hawera and Waverley race courses. The machinery used was STC and I understand that it was first operated at Waverley and was claimed to be the "First Portable Totalisator in the world". I recall seeing a framed ticket on the wall of the Secretary's office at Waverley claimed to be the first ticket sold from the equipment.

When it was decided to upgrade the STC tote a Hawera engineer Mr Noel Laird was engaged to locate and oversee the purchase of a suitable replacement. I'm not aware when this happened but it seems that the J8 / totemobile electromechanical ATL systems must have been available at that time. Mr Laird appears to have searched further afield and ended up with what I call a real bitsa of a Totalisator. Could only be called 'Portable' because it COULD be moved - definitely not 'simply moved'. It had a relay based control system similar in type to the English Bell Punch machine. I can't recall the detail of the aggregators, but I think they were based on Telephone type uniselectors.

The control equipment was housed in three large cabinets , one containing the control relays, switches, diagnostic lamps etc and the other two the 25 aggregators for both Win and Place. The 3 cabinets were mounted each on a 4 wheel chassis which were rolled out to a gantry at each track, lifted with a chain block and tackle and lowered onto a flat bed truck for moving to the next track.

Power supply was a 2 or 3 phase 50v rectifier floating across a large bank of batteries, all on a single axle trailer.

The TIMs were the Setright units which we've been talking of - Large, Heavy, Noisy and seemingly old fashioned compared with the ATL J8s. These Setright TIMs did not operate with ATL equipment.

None of this equipment including the TIMs had any identification names or marks. It seemed to us that much of it had been purchased second hand and that the control circuitry had been modified to cater for 24 starters (possibly from English Greyhound operations).

When ATL took over the Taranaki circuit in 1963 we mothballed the old equipment and converted the tracks to J8 / Totemobile operations. That's when I started with ATL.

After 2 or 3 years and an increasing number of "Clash" racemeetings when we needed to temporarily obtain equipment from out of our area, we decided to try using the old TET equipment. ATL engineers in Sydney examined sample units of the equipment which we sent over and drew related circuit diagrams for us - none had been provided by TET - and from then on we operated that equipment at Hawera with an ATL Counter Tote and J8s for Doubles betting.

As Ian mentions Bell Punch, it is interesting to note that in 1964 Automatic Totalisators Limited took over Bell Punch New Zealand Ltd purchasing all their equipment in the field, taking over the operation of all their installations and this company was later known as New Zealand Totalisators Limited.

Additionally, Ian mentions the weight of another company's equipment. ATL has been criticised from within, for sometimes having a rather obtuse view on what is portable long before Occupational Health and Safety was in vogue. Graeme Twycross, an ATL engineer in Melbourne wrote the following about ATL equipment being regularly moved in Melbourne with examples of the moves involving double shifts:

The other ongoing joke amongst the new starters was everything was portable, everything had to move from racetrack to racetrack, therefore nearly everything had handles on it, it did not matter how much it weighed. I can still vividly remember doing double header race meetings between Flemington or Moonee Valley or Caulfield and the showgrounds or worst still from Sandown to the Showgrounds, where we had to pack up all sorts of gear after the races, throw it into the back of an old Austin truck that looked a lot like a horse float with a flip down ramp at the back and drive to the other track and set it up before the first race, trying to throw down some food and drink at the same time. A Saturday double header delivered something like 21.5 hours after starting work at 8:30am and working through to 12:30-1am Sunday morning, mind you, you were stuffed on Sunday.

When Ian and I were contemplating a possible get together on Australia's side of the ditch and I suggested Roger and Sandy Penwarden may be able to join us, Ian wrote:

I must say it would be good to meet with you and with Roger and Sandy again. Roger was involved with commissioning of the PDP8 computer tote which ATL sold to Portable Electric Totalisators who operated in the Hawkes Bay and Wairarapa areas. Thats when I learned how some programmers operate - Dick Sterndale Smith seemed to work all night, and in fact did so to sort out a problem on the eve of first operation Hastings.

Comments and suggestions welcome to

totehis@hotmail.com

The "Next page" button below presents Gloucester Park where the second automatic totalisator in the world was installed in 1916.

Go back to the index

Go back to the index