This history page contains a photograph which is one of several belonging to the photo gallery pages, which are part of several technology history pages, relating to the invention of the world's first automatic totalizator in 1913 and Automatic Totalisators Limited, the company founded to develop, manufacture and export these systems.

Copyright © 2015 Email - totehis@hotmail.com

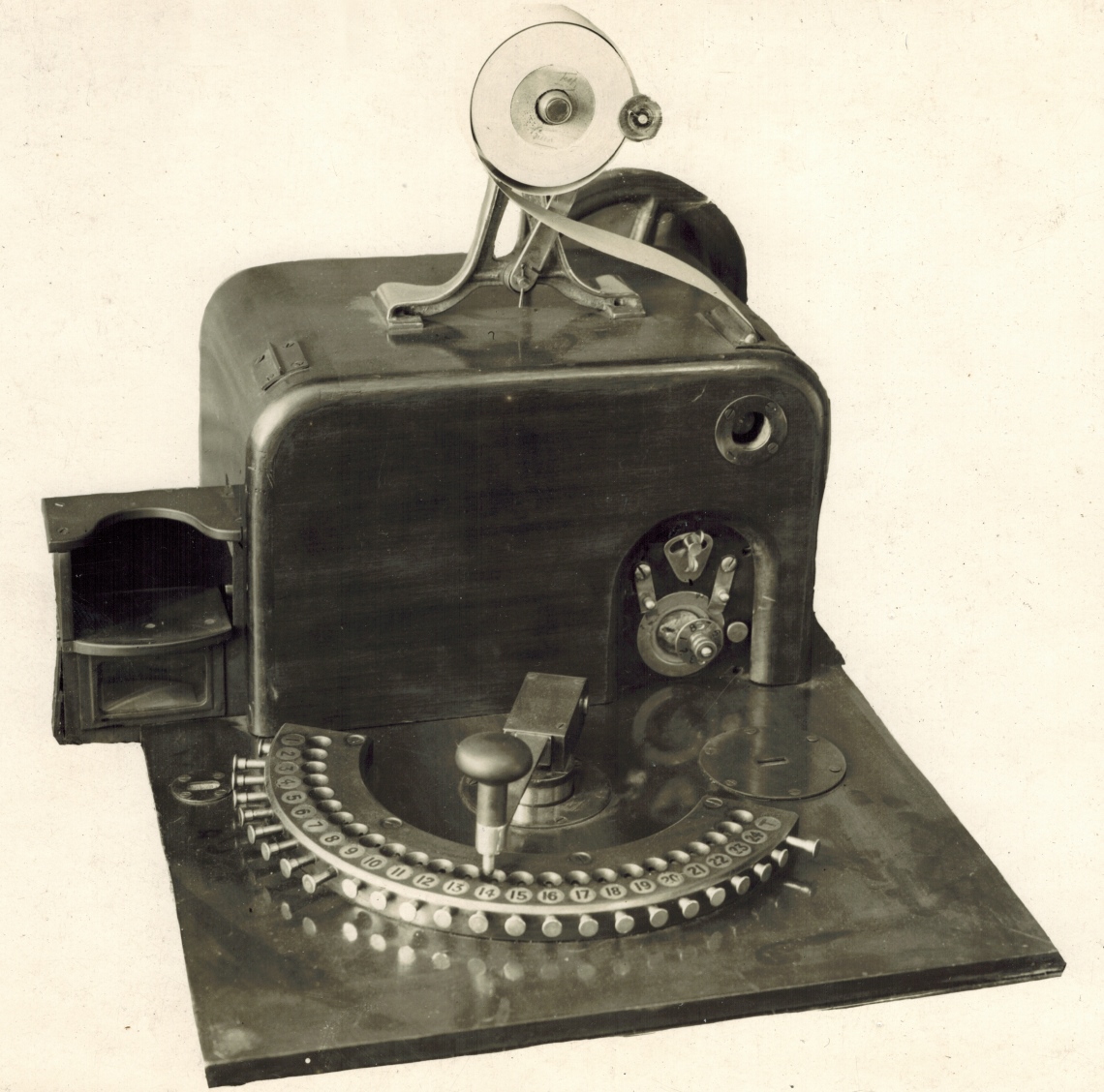

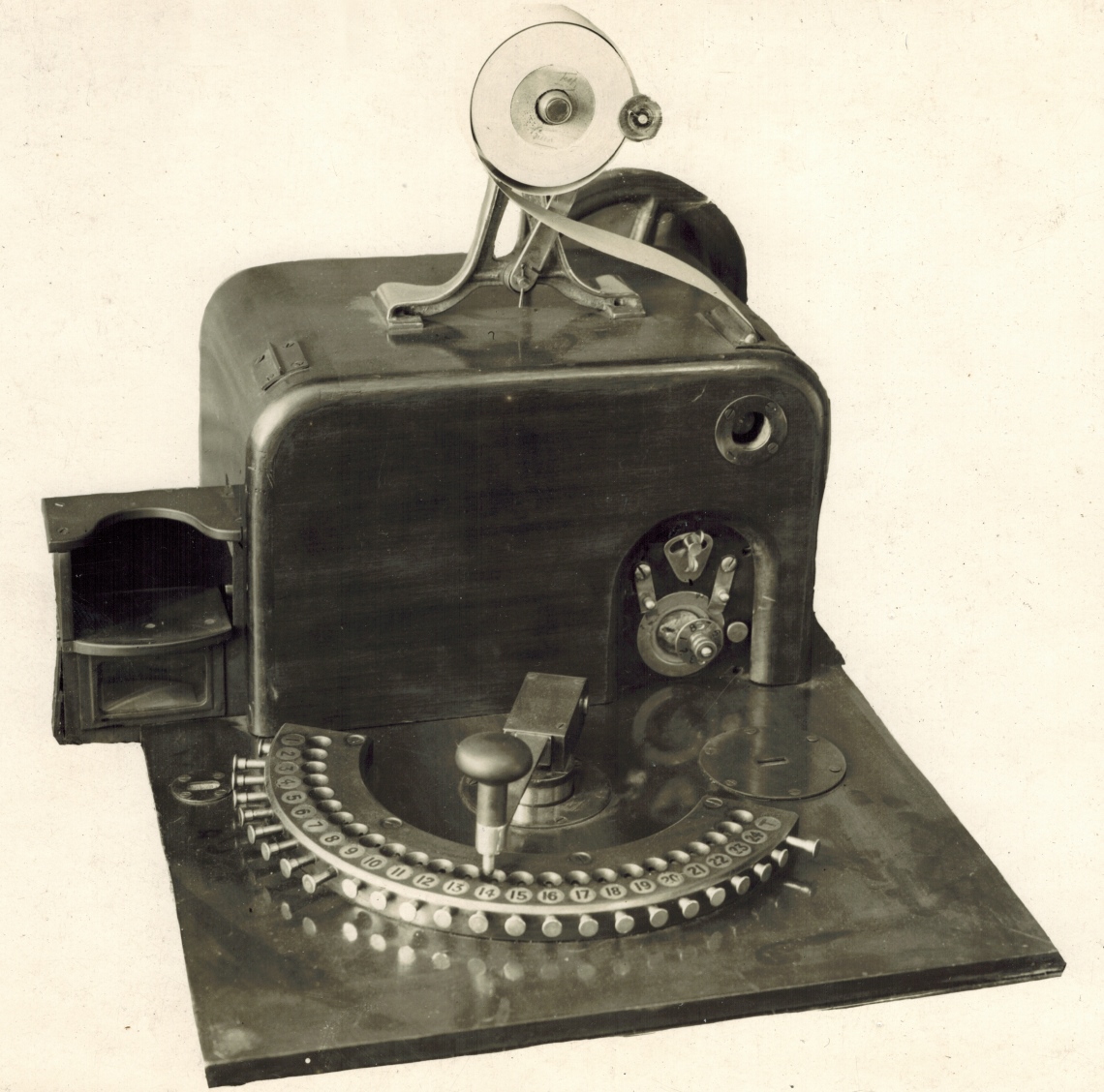

Premier TIM type used at Randwick Racecourse

The image below shows the type of TIM (Ticket Issuing Machine) that was used with the Julius Totalisator that was installed at Randwick Racecourse in 1917. Although it is the same design as the ones at Randwick, the TIM shown would not have been one of the 150 terminals installed at Randwick in the 1917 system as it only caters for 24 runners and that system supported 42 runners. Ironically this TIM would have been usable on the later generation Julius Totalisator which was installed at Randwick in 1935, as that system had a maximum field size of 24. As page two of a company document titled Straight Betting, shown in the image below titled Page 2 Straight Betting, which relates to the 1917 Randwick system, shows a copy of the first image shown below and this document was written in 1922 or soon after, the TIM shown in it and below, will not have belonged to the second Julius Tote at Randwick installed in 1935.

It is additionally interesting to note that, although the bottom left image in Page 2 Straight Betting shown below, shows a TIM that would not have been used in the 1917 Julius Tote installation, the very same page contradicts the implication that this is a 1917 Randwick TIM, by stating in the top right text box, that this system provides for 42 starters. In conclusion, as there are several other sources confirming the 1917 Julius Tote supported 42 starters, the TIM shown did not belong to the 1917 Julius Tote, although the same model of TIM, which looks the same except for supporting 42 starters did.

More after the image...

Click on the image to go back to the photo gallery

There are no photographer's markings on this print

I thought for some time that the image above, as with the bottom left picture in the image below titled Page 2 Straight Betting, contained a blemish, which I mistook to be a drawing pin mark, on the right hand perimeter of the paper roll on top of the machine. Closer examination revealed that, what appears to be a blemish, actually is a well worn washer, secured to its supporting shaft by a split pin. This assembly presumably acts as a paper guide and a paper roll unravelling preventer! It seems to be supported by the bracket rising at about 30 degrees right of vertical, from the centre of the lower arch of the paper holder. This bracket is pivoted at its base which is also retained on its shaft by a split pin.

George Julius named his product the Premier Automatic Totalisator and he referred to the TIM shown above as the Premier Issuer. A video clip in a British Pathé webpage shows this "Premier Issuer" in use at a Sydney racetrack in 1927.

In the British Pathé video clip a seller is shown operating one of these machines. The drive pulley which can be seen at the right rear of this TIM below the paper holder is continually rotating, driven by overhead pulleys on drive shafts that supply every TIM in the tote house in which these machines were installed. The operator in the video clip operates the machine by rotating the handle to the required runners and pressing the knob on the handle down to initiate a sale. The TIM ejects the issued tickets into the box attached to the left hand side of the vertical cover where they are collected. There is one difference I have noticed between the image above and the TIM shown in the the British Pathé video clip. The assembly mentioned above which I presumed acts as a paper guide and a paper roll unravelling preventer, acts on the left hand side of the paper roll instead of the right hand side.

An indented archway rises up on the lower right section of the vertical case of the machine, from the rear of the horizontal surface containing the runner selection handle. Inside this archway, there is a circular metallic attachment to the case. Within the circular attachment to the case is the end of a shaft that rotates. A circular coin like metal disk is attached to this central shaft offset from centre and sits proud off and eccentric to the original circular attachment to the case. When the machine issues a ticket this disk orbits anticlockwise around the central shaft one revolution. Some of the numbers 1 through 8 can be seen on this disk in this image, around its perimeter. As 8 races per meeting is common and the Australian Jockey Club Instructions for Ticket Issuer Operators presented below refer to changing the race number, this disk might be the means of achieving the race change.

Also within this indented archway, above the circular attachment just discussed, there is another attachment that looks a little like a bottle opener. In the arched mouth section of the "bottle opener", there is a butterfly nut. This appears to be some form of adjustment, probably something to do with the paper transport system, print head or platen. Presumably the butterfly nut can be released and the nut and whatever else is attached to it can be moved along the arched opening to be secured again at the right location, tension or pressure. The two metal strips that rise up from the circular attachment to anchor points near the sides of the bottle opener like attachment are another mystery. I am not sure if they are electrical contacts or purely mechanical. I do not think it is possible to determine their function from a photograph and it would require a physical example of one of these machines for examination, to answer these questions. One final question remains in this indented archway section of this TIM. Starting at the top of the original circular attachment proceeding clockwise around to the 90 degree position, there is a small circular object that looks like a small knob or button. As the Australian Jockey Club Instructions for Ticket Issuer Operators presented below refers to turning the switch off if the machine gets out of order for any reason, this knob or button may control the switch being referred to.

It is interesting to note that the scratchings are implemented on the machine. The British Pathé website video clip has a caption Human error is eliminated - error is impossible. It is impossible to back a non runner. This is achieved by the operator entering the scratchings on the machine prior to operating. The TIM has an arc with holes on the top, graduated with runner numbers. To select a runner number the handle is moved to the desired number and the handle is depressed sending a locator into the associated hole in the arc and initiating a transaction cycle. Prior to operation, the operator makes sure the radial lockout buttons at the outside perimeter of the arc are pressed in for every runner that is a scratching or a runner number corresponding to a horse number in excess of the highest runner in the race. Every valid runner number should have its corresponding radial lockout button pulled out with every other lockout button pressed in. This will allow every valid runner to be selected and every invalid runner number will not allow the sell button on the handle to be depressed because of the corresponding pushed in lockout button. As can be seen from the image, runners 10 through 24 have been locked out suggesting that the highest numbered runner in the race is 9. Number one is also locked out indicating it is a scratching. T which is also enabled allows a Test Ticket to be printed if selected.

In the AJC (Australian Jockey Club) document below titled Totalisator Notice - Instructions for ticket issuer operators, the first item includes instructions on how to set these runner number radial lockout buttons. It refers to closing and opening up horse numbers, which refers to pushing in and pulling out these radial lockout buttons.

This must have been the first method of implementing scratchings. Later this was controlled in the machine room where every adder associated with a non runner would be disabled prohibiting a transaction cycle to be initiated from any TIM, on the adder associated with the non runner. In the end the scratchings were input into the system via a remote Raceday Control Console which disabled the selected adders at one centralised location rather than every operator entering the scratchings on their machine further minimising the possibility of error. There is an image of a Raceday Control Console later in the photo gallery in the Harold Park section.

I have presented the following commendation from the Secretary of the AJC as it refers to the TIMs and the selling staff operating them. The Secretary refers to these TIMs as Automatic Totalisator Machines, which are of the type shown in the image above. C.W.Cropper Secretary Australian Jockey Club wrote on 22 July 1922:

I have pleasure in stating that the "Premier" Automatic Totalisator Machines, which were installed at Randwick Racecourse and are operated by your Company on contract under the supervision of the Club, and which were first used at the Club's Spring Meeting, 1917, have, since their installation, given complete satisfaction. Their accuracy is unquestionable and the rapidity with which tickets are issued by the experienced operators leaves nothing to be desired.

You will remember that during the last twelve months the ticket issuers in the Saddling Paddock Totalisator have been replaced with the latest model, and the capacity of the machinery re-modelled to operate 100 machines --73 of which are now in operation, giving the most satisfactory results.

C.W.Cropper mentions the experienced operators. During my time in the totalisator industry which began in 1977 there was always competition amongst some of the operators to be regarded as the fastest and most accurate.

Regarding C.W.Cropper's testimonial above, initially I only provided the first paragraph of it on this website as the company document I extracted it from only had the first paragraph. Recently I found a second company document that contained this testimonial, which included the second paragraph. On the 22nd of July 2017 I added the second paragraph to the above quote. Whilst I was adding this paragraph, I happened to notice that it was 95 years prior to the day, that C.W.Cropper had written this testimonial on 22 July 1922!

The Old Main Tote at Randwick 1917

The above image shows the old Main Tote House at Randwick which was custom built to house part of the 1917 Julius Tote. At the ground level are tote windows. The narrow windows in the octagonal left and right wings of this building, house the selling windows, each of which has one of the TIMs like the one shown at the top of this page in it. There are nine such windows visible in each octagonal section, however these windows continue around these wings of the building. The paying out of dividends in the early to mid 20th century was done manually. Some of the windows in this Main Tote House will have been dedicated to payout. Some of the windows in this central section have the word Change on them. The selling windows have the window number and the bet value for the window on them. Usually the best operators are assigned to the highest value windows.

The following AJC notices would have been hanging in the tote house in the image above and the first notice titled INSTRUCTIONS FOR TICKET ISSUER OPERATORS, relate to the TIMs like the one shown at the top of this page:

Notes on the following 1917 notices:

- The underlined texts in the following paragraphs are not hypertext links they are replications of the original document.

- The Julius totes had manual payout requiring Payout Clerks.

- It is evident that these 1917 TIMs, were provided with two staff each to operate them, a Seller and an Issuer Operator. I do not think this was a requirement of the system to have two operators, but a legacy operational requirement. It is interesting that the Issuer Operator is instructed not to listen to the customer in this two person operation. I have read that when the Julius Tote at Longchamps started operations in 1928, the French race-club continued a two man operation, despite being advised that a single operator is all that is required. The two operator per selling window policy was continued to keep the customers happy.

- The manual effort required to achieve certainty in payment is interesting with the dividends being calculated up to ten times by each Paying Clerk then cross checked.

- It is also interesting to note that the technical staff maintaining these systems were called Mechanics. In the late 1970s, after implementing the first on course computer based totalisator systems in Brisbane, which superseded Julius totes, the technicians and engineers working on the computer systems were also called Mechanics by the operators. This continued for decades and still in 2008 you would have the odd call now and again for a Mechanic!

Australian Jockey Club

TOTALISATOR NOTICE

INSTRUCTIONS FOR TICKET ISSUER OPERATORS

First see that ticket paper is correctly placed in the machine. Try one or more test tickets, noting that race number is correct and that sufficient ink is on machine (reserve all test tickets for manager). Close up all horse numbers on machine when window is closed. Await the hoisting of board showing final scratchings, then open up horse numbers shown. Be ready to issue tickets immediately window is opened.

Do not issue any tickets until instructed to do so by the ticket seller. Pay no attention to numbers called for by investors, the ticket seller will ask you for tickets required.

Should a ticket be issued through any cause and not sold, it must be handed to the Telephone Operator immediately the window is closed, with an explanation showing why it was issued, or otherwise the Ticket Issuer Operator will be held responsible.

Immediately the window is closed, remove paper from issuer, leaving two partly printed tickets on roll, and put on new paper for next race. Change race number and proceed as before.

Should issuer get out of order from any cause, turn switch off at once; the window should be closed immediately and signal given for Mechanic. On no account try to rectify same yourself; do not try to issue any more tickets until Mechanic has left cubicle.

BY ORDER OF THE COMMITTEE

DECEMBER, 1917.

The following AJC notice provided instructions for the Paying Clerks. It may seem primitive that this 1917 totalisator had a manual payout system. This is an interesting point which demonstrates that totalisator systems did not rapidly arrive at the functionality that we are accustomed to nowadays. It was a process of development over many decades. Manual payout of dividends persisted long after the 1917 Julius Totalisator well into the computer era. I joined Auotmatic Totalisators Limited in the 1970s. I worked on the development of a computer based totalisator system which replaced the Julius Totalisators in the Brisbane Region. This Brisbane project was a milestone for Automatic Totalisators Limited, as it was the first Sell-Pay system developed by the company. Although the company had developed many computer based totalisator systems prior to the Brisbane Project they were all Sell-Only systems requiring manual payout!

Australian Jockey Club

TOTALISATOR NOTICE

INSTRUCTIONS FOR PAYING CLERKS

Get cash from bank before first race. Get cash afterwards from banker or selling clerk as directed, giving I.O.U. for same.

When dividend is posted, work out dividends up to ten times and check same with next paying clerk, getting him to initial sheet, you initialling his.

Open up window when signal to pay is given, and keep it open until it is clear; on no account close the window too soon. Fill in list of tickets paid, and return all notes (retaining silver), tickets paid and list to banker, who will give receipt for same. Each ticket must be cancelled as it is paid. Carefully scrutinise ticket and check same with sample ticket given you before paying same, so as to avoid paying out on wrong tickets; as paying clerks will be held responsible for any mistakes made.

Should a legitimate doubt exist about tickets, ask the person tendering same to go to commission room or manager's room.

Should any ticket be presented which appears to be forgery or has been altered (use great discretion in doing this), obtain posession of same and ring the bell under counter, which will immediately bring a detective; then hand ticket to the detective, pointing out person who tendered same.

Should paying clerks be running short of change, pull out the sign for runner. Do not wait until change is exhausted; signal in time to prevent any stoppage in paying out.

BY ORDER OF THE COMMITTEE

DECEMBER, 1917.

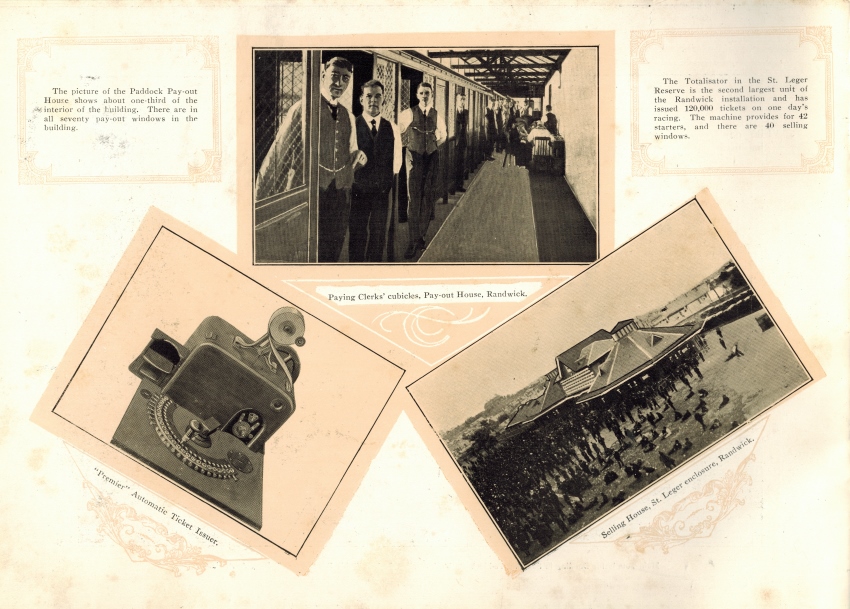

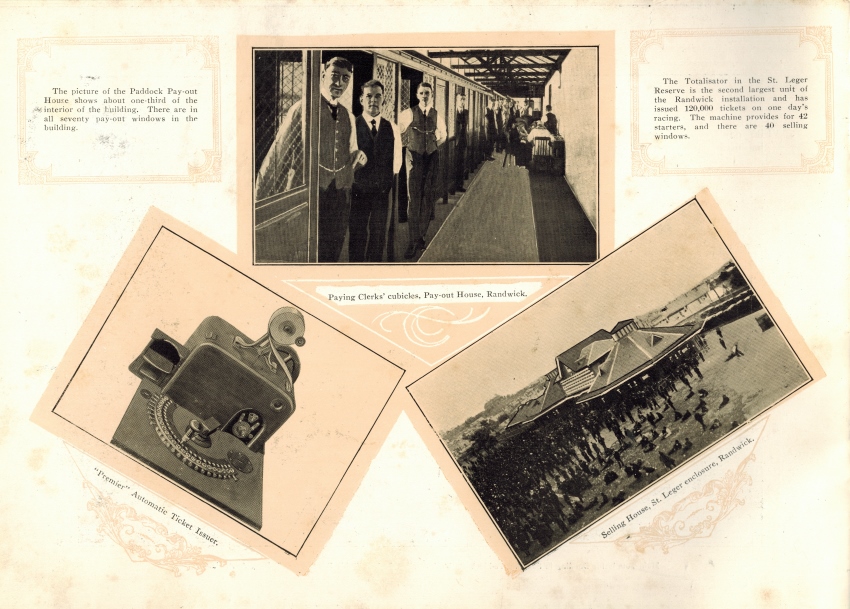

The image below shows page two of a company booklet titled Straight Betting. The top image of the page is annotated Paying Clerks' cubicles Pay-out House Randwick. This shows some of the Paying Clerks to whom the above instructions apply.

The text box in the top left corner of the image below reads:

The picture of the Paddock Pay-out House shows about one-third of the interior of the building. There are in all seventy Pay-out windows in the building.

Also in Page 2 of Straight Betting shown below, bottom left there is an image of a Tim titled "Premier" Automatic Ticket Issuer, like the one at the top of this page. This is proof that the image at the top of this page shows the type of TIM used in the 1917 Randwick System. The note in the text box, top right in the image below, demonstrates that the "Premier" Automatic Ticket Issuers shown bottom left, were busy in the St. Leger Reserve and reads:

The Totalisator in the St. Leger Reserve is the second largest unit of the Randwick installation and has issued 120,000 tickets on one day's racing. The machine provides for 42 starters, and there are 40 selling windows.

Page 2 Straight Betting

The image above, as well as the rest of the Straight Betting booklet, is a historic example of artistic company product promotion in the early 1920s. Low image resolution was probably normal back then.

Thanks to Bruce Rutter, who held multiple management positions with Automatic Totalisators Limited finally becoming General Manager, for giving me his copy of Straight Betting. Although this booklet is elegant with an ornate cover, it seems to be a pre release version of it. There is fountain pen writing on the front cover which reads Mr Raymonas with memos inside written below. The text has deletions and additions marked in it, some in pencil and others in fountain pen.

An original copy of a company document titled The Premier (Julius) Automatic Totalisator, contains a low resolution picture showing a man operating a Ticket Issuing Machine (TIM) with the following text beneath it: FIG 12. Interior of ticket selling cubicle on the Randwick, N.S.W., Racecourse, showing "one-man" operation. The ticket issuing machine this man is operating, looks identical to the one in the image at the top of this page. Again this is confirmation that the TIM at the top of this page is of the type in use with the 1917 Julius Tote at Randwick! Additionally the "one-man" operation mentioned in this document demonstrates that a single operator was normal for the Julius tote TIMs and the use of two operators per TIM, as initially existed with the 1917 Randwick system and with Longchamps Racecourse in France, was a continuation of the way it was done prior, to keep the customers satisfied.

The mentioned company document has the following text associated with the image of a man operating the TIM, or what was then known as the Premier Ticket Issuer. This extract is the sixth in a sequence of extracts from the company document contained in multiple Photo Gallery pages of this website. This extract immediately follows the previous extract. The previous extract can be read in the Photo Gallery page accessible by clicking on the image at the top of this page and scrolling down in the index table to the title that starts with the text Longchamps Paris 1928 - ... and selecting the image thumbnail below that, which has associated text starting with the words A close-up view of the Longchamps pavilion... :

"Ticket Issuers."

The Premier Ticket Issuer is a machine that has been perfected as a result of many years' experience, and, in its present form, is now in use on Racecourses in many different parts of the world. The fundamental consideration in the design of such a machine to be suitable for Racecourse betting is that each such machine should be capable of printing and issuing tickets on any horse in the race, and where two totalisators are installed, one for "win" and the second for "place" betting, the same issuing machine must also be capable of issuing tickets on either of these two machines. This is essential because many bettors not only require to invest on more than one horse in a race, but also frequently wish to invest some of their money on the "win" machine and the balance on some other horse on the "place" machine. If it were necessary to go to different windows, either to get tickets on one or other of the two machines, or to record bets on different horses, great congestion and inconvenience to the betting public would result.

The speed of the betting--that is to say, the speed at which the betting crowd can be handled--depends very largely upon the time required to take and count the money paid by the bettor, and as in most Racecourses the room available for the installation of selling booths is very limited, it is essential that the business should be handled adequately and comfortably by a minimum number of such booths, apart altogether form the increased first cost and the cost of operation of the selling machine with which each additional booth has to be equipped. It is most important, therefore, in view of these considerations, that the machine that is to print and issue the tickets should be capable of doing so at a high rate of speed, and in this connection the Premier Issuer is as fast as any ticket issuer at present available for the work, and very much faster than the majority of such machines.

Another very great advantage of the Premier machine is that it requires one hand only for its operation, to issue a ticket on any horse, and on either the "place" or the "win" machine. This leaves the operator's other hand free to take and count the money paid in by investors. In this way, tickets have in practice frequently been printed and issued at rates up to and sometimes even exceeding 40 per minute, the machine itself being capable of printing the tickets at a speed of over 100 per minute.

In the Pari Mutuel system of betting, and also in many forms of totalisator, pre-printed tickets are used, necessitating the preparation of an enormous number of tickets, consecutively numbered, and placed in suitable receptacles, in each selling booth. 80 per cent. of such tickets, on the average, remained unsold at the end of the betting on any race, this being due to the impossibility of making any accurate determination beforehand of the number of tickets that are likely to be required on any particular horse. The availability of these unsold tickets also introduces a serious risk of fraud, as such tickets could be presented for payment at a dividend paying window after the race, should such unsold tickets pass into the hands of an unscrupulous person.

In the Premier machine the paper used for the tickets, whilst of a special type to make imitation difficult, is absolutely blank, so far as any printing is concerned, until it passes through the issuing machine and the printing of each ticket is not done until the operator in charge of the machine has received the money representing the purchase of that ticket; and at the same time, also the registration of the sale of the particular ticket has been passed on to the adding machine and duly recorded on the Indicators. This arrangement not only eliminates the great loss involved in the printing of enormous numbers of surplus tickets, but also reduces the chance of the fraudulent presentation of unsold tickets.

A typical installation of Premier issuing machines in a small Racecourse equipment is shown in Fig. 9, and in Fig. 10 an outside view of the issuer with its operating handle, its paper feed, and its "number" dial is shown... Continued below.

Figure 9 in this document is titled Interior of Totalisator Building, showing "Premier" Ticket Issuing Machines installed in 1929 for the Galle Gymkhana Club. Ceylon. The image in this document is so low resolution that it is not worth reproducing here. There is an image in the photo album of this website that is similar however. To view this click on the image above and scroll down to the image thumbnail with associated text The Julius Tote J5 Ticket Issuing Machines in Singapore. I have included a reduced copy of this image next.

Singapore Turf Club J5 Ticket Issuing Machines

Figure 10 in the company document shows a J5 Ticket Issuing Machine (TIM). This is the same as the machines on the tote benches in the Singapore system image shown above, although in this tote house image, it is not possible to discern any details of these TIMs. The J5 is similar to the image at the top of this page although it is more modern than the Premier Ticket Issuer. A major difference between the two is that the selector knob on the J5 swinging arm, can be moved longitudinally to either a forward or backward position, which selects the Win Pool or the Place Pool respectively. Another difference, obvious from, these images, is that the J5 has the paper roll mounted separate to the machine and in the case of the Singapore Turf Club system, you can see the paper rolls hanging on the partition between each selling window rather than mounted on top of the machine. Finally, another short extract from the company document which follows directly on from the extract above and completes the paragraph:

"Ticket Issuers."

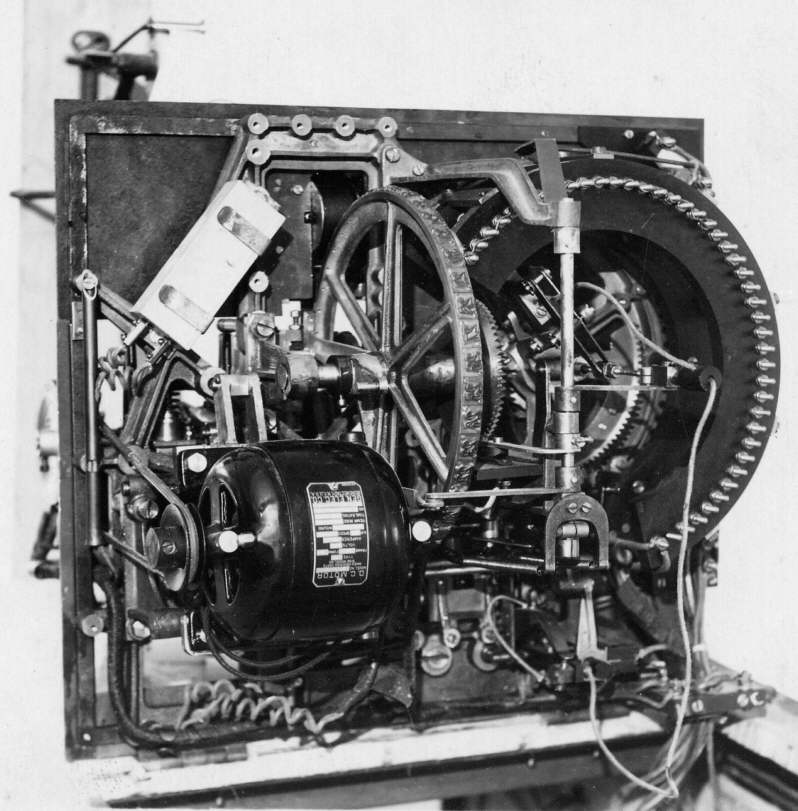

Each issuer is mounted in such a way as to make it accessible for ready inspection and each is driven by means of an independent electric motor, so that no shafting or belting of any kind is required, and an inside view of a Premier Issuer, raised for inspection, is shown in Fig 11.

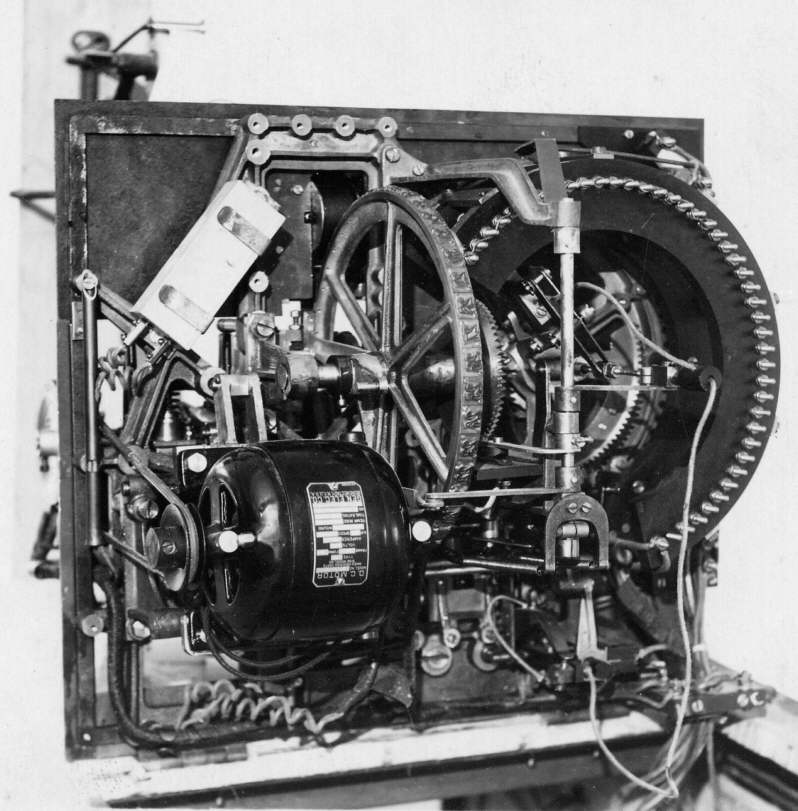

The above extract refers to an independent electric motor. The image below of a J6 workings which is similar to the J5 being described shows the electric motor in the bottom left hand corner. This highlights another difference to the machine shown at the top of this page, which has an external drive via a belt, which is not shown in the image, but would drive the pulley visible at the top right of the machine below the paper roll, if the machine was installed somewhere. This further confirms that the J5 is a more modern TIM than the one shown at the top of this page.

Figure 11 shows what is probably a J5 Ticket Issuing Machine in its raised position which is its maintenance position for access to its workings. There is an image in the second page of the Photo Gallery of this website that is similar however, it is of a J6 rather than a J5. To view this click on the image at the top of this page and scroll down to the bottom of the page and select the Next page option in the navigation bar. Next, scroll down in the image thumbnail directory to the Ticket Issuing Machines heading and select the image thumbnail with associated text starting "The inside of a J6 Ticket Issuing Machine 1935..." I have included a reduced copy of this image below:

The inside of a J6 Ticket Issuing Machine

The next extract from this company document titled The Premier (Julius) Automatic Totalisator, which immediately follows this extract, can be read by clicking on the image at the top of this page and scrolling down in the index table to and selecting the image thumbnail in the "Longchamps Paris 1928 - ..." section, with associated text starting An image of one of the 273 J5 Ticket Issuing Machines at Longchamps...