This page contains a photograph which is one of several belonging to the photo gallery pages which are part of several history pages relating to the invention of the world's first automatic totalizator in 1913 and Automatic Totalisators Limited, the company founded to develop, manufacture and export these systems.

Counter Tote Brochure Courtesy Chris Robertson

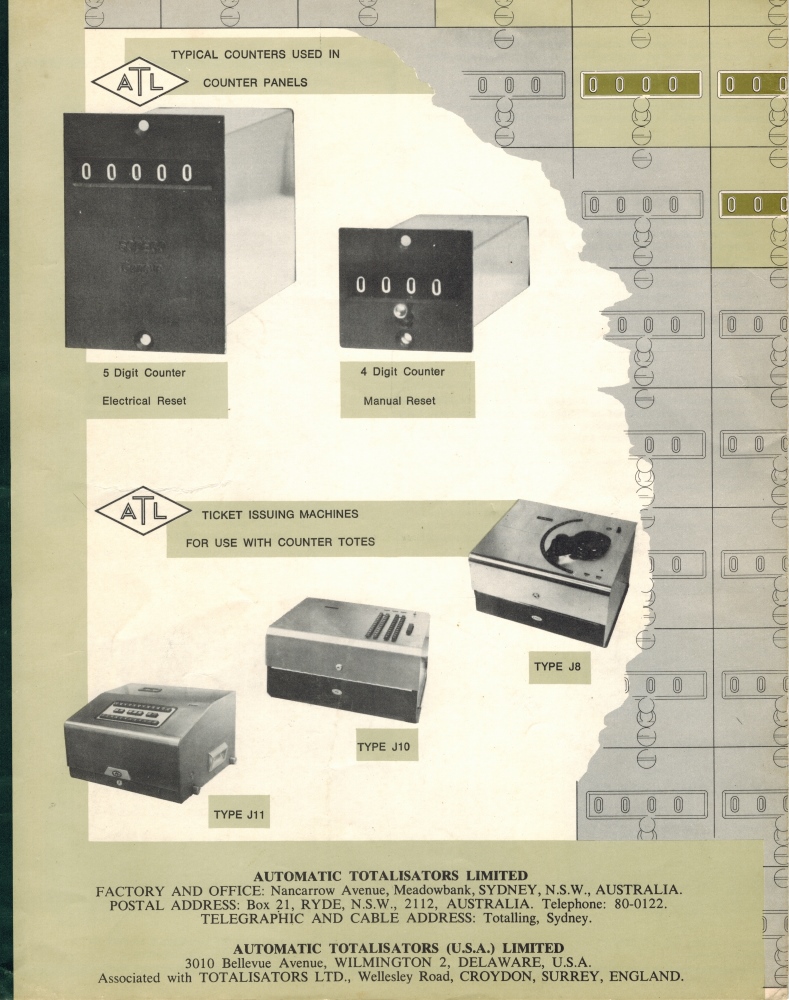

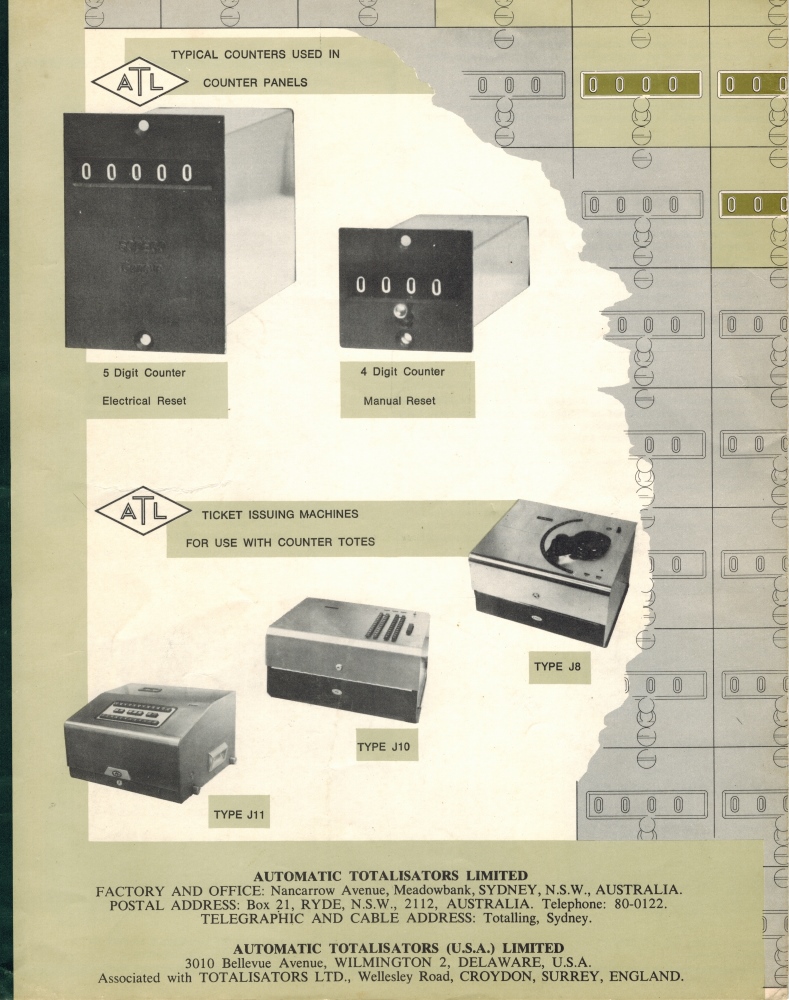

These images show the front and back of a Counter based Totalisator, ATL Product brochure in the form of an A4 size card. This and other cards like it on this website were provided by Chris Robertson, an ex customer of the company and an expert on its products and installations around the world. This brochure was probably produced in the 1960s. More after the images...

Click on the image to go back to the photo gallery

This is the front of an Automatic Totalisators product promotion card

Click on the image to go back to the photo gallery

This is the back of an Automatic Totalisators product promotion card

The Counter Totes are an example of the company keeping abreast with new technologies. The Julius Totes quickly went from being purely mechanical to electromechanical. Here we see a much later adoption of relay logic which was made popular by the telephone exchange industry. We are seeing the beginning of a transition of increasing levels of electronics which finally led to the adoption of digital computers as the basis of totalisator design.

Don McKenzie wrote the following about the ATL counter totes on his website relating to Automatic Totalisators Limited in Victoria:

We had two portable Counter Totes. Basically one for the city interstate tracks, and one for the country. These were very slow systems, possibly 250ms a bet, or four bets a second. Each bet represented a 50 cent transaction. Relay logic was used to allow each TIM access to the counters for the time required to place each bet. Say we had a $10 TIM (20 counts on the counter), 2 by $2 Tims, and 8 by 50 cent TIMs. A total of thirty six 50-cent bets. During heavy betting periods, this would represent a 9 second delay, before the next machine could issue a ticket.

I had a reasonable amount of relay logic experience from my days in P.M.G telephone exchanges, and I came up with a new relay access box, and two additional counter boxes, that allowed the $10 bets to go through as a single bet. It meant that instead of a single pair of counters, one for win, and one for place, we had two sets. One set that counted $10 bets, and the other set counted 50-cent bets. The dividend and odds calculator staff then had to adjust their figures correctly to suit. Made this baby counter tote really scream along. The $10 TIM could now bet at $40 a second, instead of $10 every 9 seconds. That is close to 40 times the speed of the original $10 TIM. Never missed a beat.

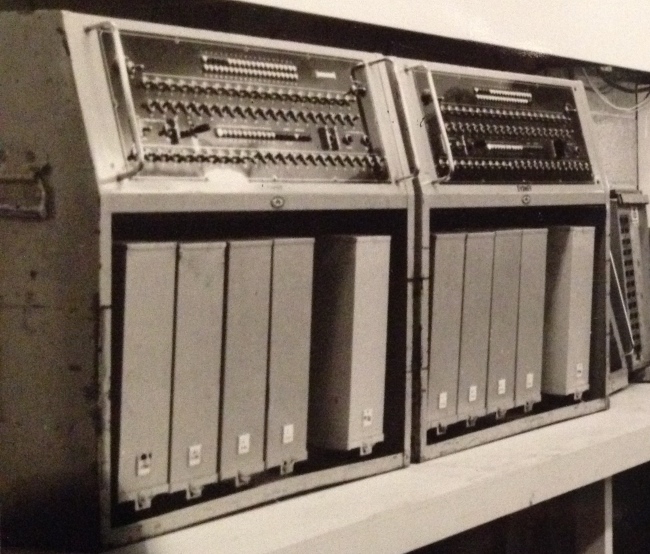

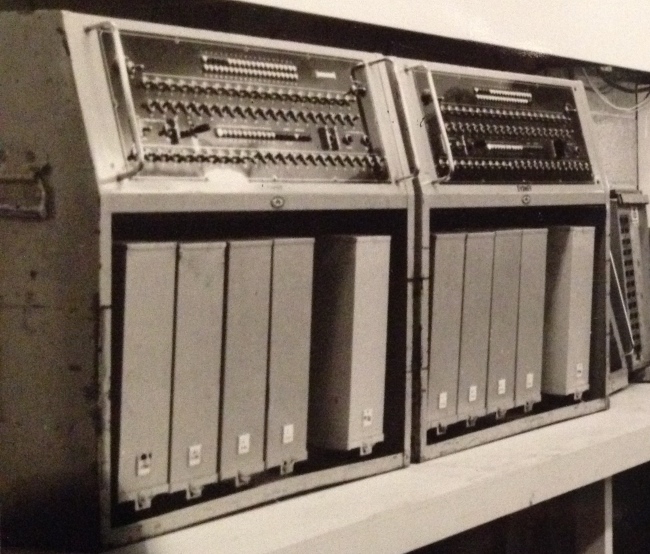

A Counter Tote at The Gabba Greyhounds Brisbane

The image above shows two counter totes at the Gabba Greyhound Racing Club at Woolloongabba Brisbane when the Cricket Ground shared the facility with the Greyhound Club. This system was in operation prior to 1979 when it was replaced with a computer totalisator system, a project I worked on. The boxes inside the frames are relay logic counter boxes and relay access boxes. There are two frames, presumably one for the Win Pool and the other for the Place Pool. These are portable units and as can be seen from the near end with the carry handle, they have done a lot of miles. Apart from the scratches, the left hand unit was probably dropped as it has sustained a dent in the casing at the bottom near the centre. The display panel for this counter tote is to the right of the counter totes seen in the image above, on top of the bench.

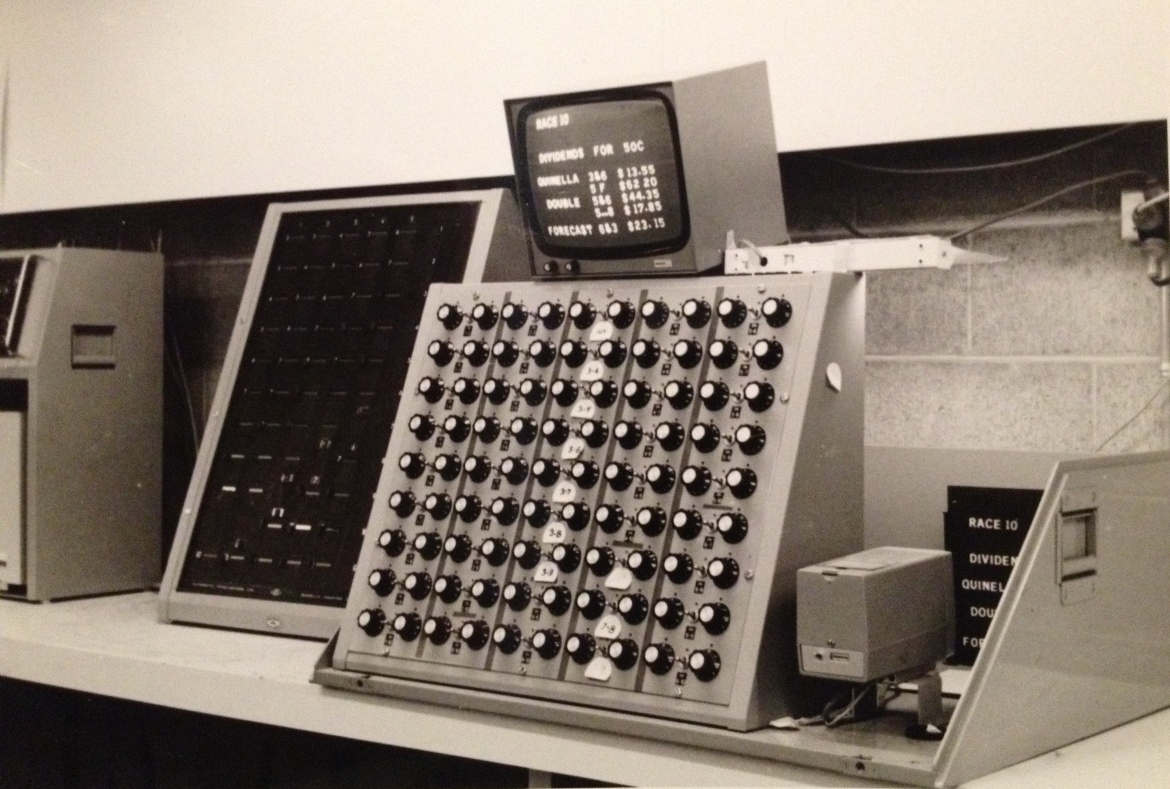

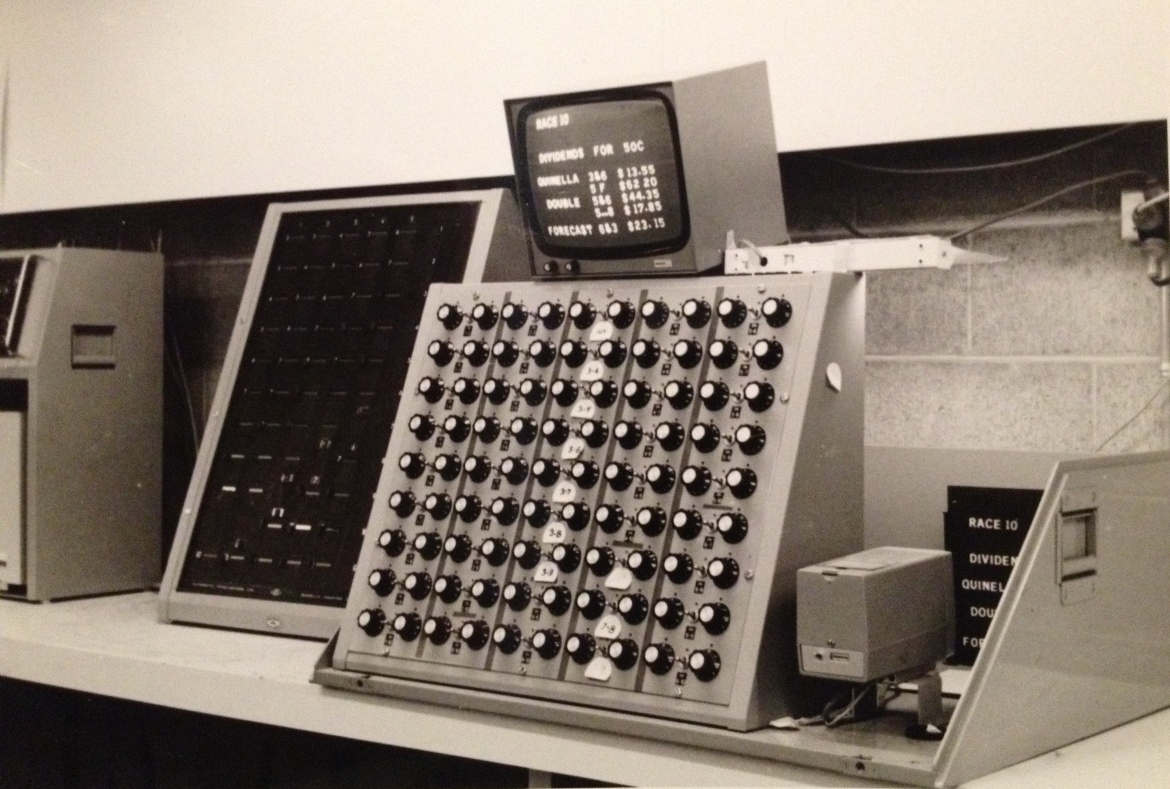

In the image below, display equipment can be seen on the right hand side of a similar Counter Tote at the Gabba to the one shown in the image above. The right hand end of the right hand counter tote can be seen on the bench on the left hand edge of the image below. To the right of this is a dark tall rectangle shaped panel leaning backwards. This is the Counter Tote Display Panel, which Neville Mitchell calls the W/P Counter Console, W/P specifying the Win and Place pools. Neville was a long serving ATL (Automatic Totalisators Limited) engineer and manager and is the best company historian I know. To the right of this is the television display generating system for odds and dividends. This old display generating system is described in another page of this website. To read this, click on the image at the top of this page to return to the Photo Gallery. Scroll up in the Photo Gallery index to the thumbnail showing the image above, which has the associated text starting with A bygone dividends and odds TV display method... and click on that thumbnail. Neville calls the panel with all the knobs on it in the image below the Odds Display Manual Control Console.

Equipment right hand side of a second Gabba Counter Tote

I got the impression from what I could make out of the fuzzy permanent markings and notes on the equipment in the image above, that the W/P Counter Console and the Odds Display Manual Control Console may have been for a Doubles or Quinella Pool. When I suggested this to Neville Mitchell, he wrote the following in response. Neville's reference to this photo refers to the second image above:

There was both Doubles and Quinella counter totes in the mid 1970s. All worked on the Julius series circuit, with the counter taking the place of a adder, and access relay system operating as a distributor. This photo is a 24 starter W/P counter tote. The spare relay box connectors were for the Access relay system. In later models a Routiner was available for automatic testing of the counter panel.

I wrote to Neville to get some idea how the W/P Counter Console and the Odds Display Manual Control Console were used. I also asked if the Odds Display Manual Control Console drove a Nixie Tube based display panel. A few Nixie Tube devices based on Nixie Tubes that provided the digits 0 through 9 in a single neon filled tube, were still around when I started in electronics engineering in 1970. Neville's reply follows:

This control panel was manually operated using the knobs to enter data supplied by the odds calculator person, who read the counters on the counter console and using a Julius odds calculator determined the odds, to be set up on the control console which was then displayed on a Videoed 7 segment Nixie tube odds display panel. The MOVITEX display panel in the photo is for results and dividends for W/P only.

There was no automatic odds generation that was done manually reading the horse total and GT to set the odds via the knobs on the control console.

The Movitex display panel Neville refers to is the black board with white characters on it that the video camera is pointed at in the bottom right hand corner of the image above.

An image of a much larger Doubles Counter Tote display panel can be seen in the image below titled Counter Tote for Daily Double.

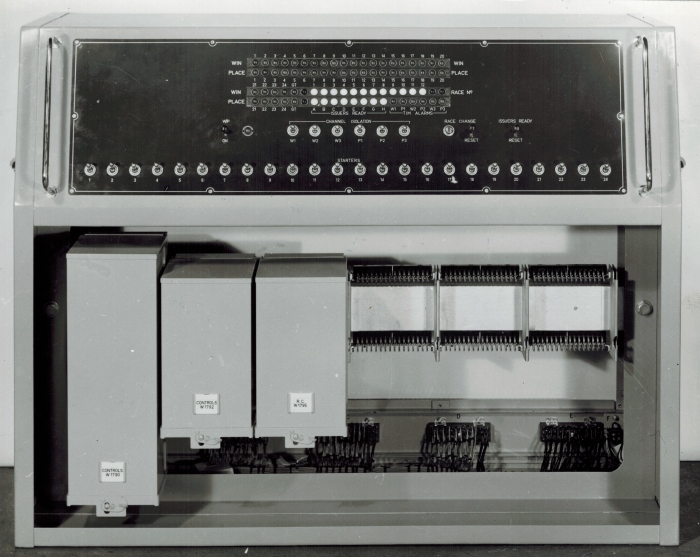

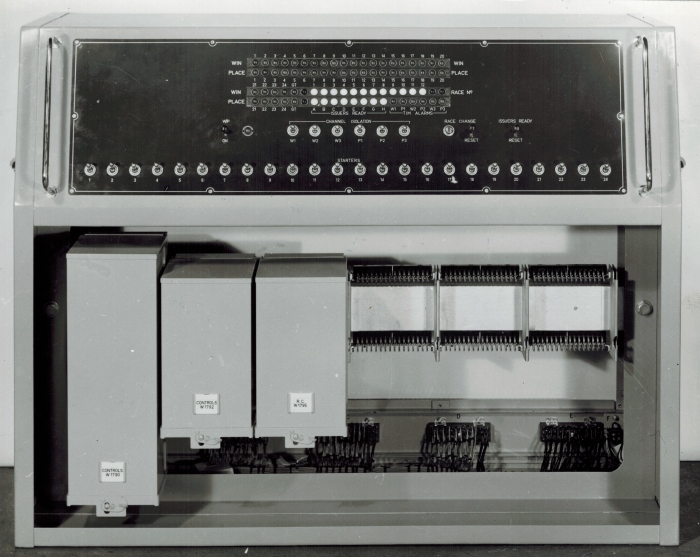

A Brand New Counter Tote

In contrast to the image of The Gabba Counter Totes which are well worn, this is a brand new one. It also seems to be a more modern design as the ones at the Gabba seem to handle a single pool each and the new one seems to handle both Win and Place pools. This image has only three relay logic units plugged into its module bay and the three available slots can be seen to the right of the populated ones giving a good view of the connectors into which the modules are plugged. The writing on the three modules present is from left CONTROLS W1790, CONTROLS W1792 and R.C. W1795. The W numbers are probably drawing numbers of drawings that define the contents of each module.

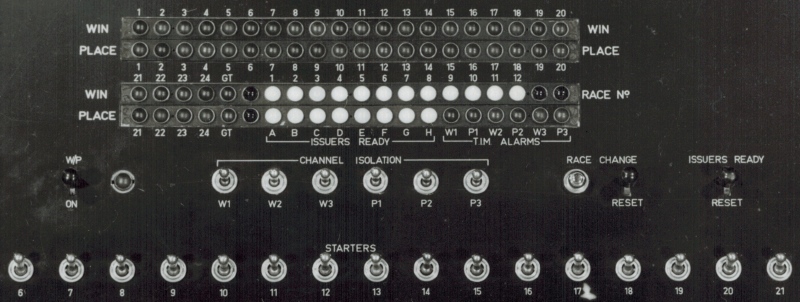

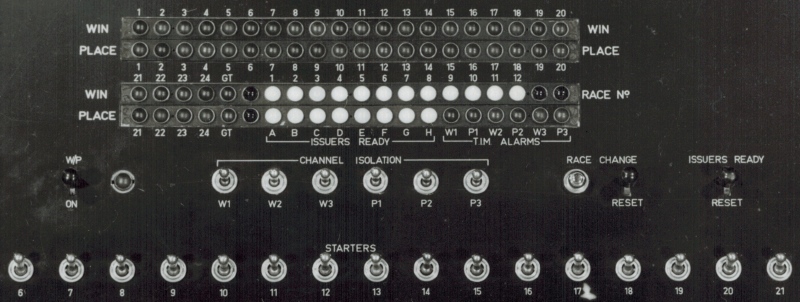

Expanded view section of Control Panel

To save you from squinting at the top of the previous image, the above image is a close-up of part of the control panel of the Brand New Counter Tote. The only parts that are missing are the STARTERS switches for runners 1 to 5 and 22 23 24.

I did not understand why all twelve race numbers are illuminated at once as I was certain that this equipment would only operate on one race at a time in sequence. Additionally, it seemed odd that all the ISSUERS, alternatively known as TIMs (Ticket Issuing Machines), which seem to be grouped into banks A through H are all in the ready state, as the module bay at the bottom of the rack is not fully populated. I rightly or wrongly concluded that all TIM groups would not be fully supported in this configuration due to the missing modules as it was not required to support that amount of TIMs. Neville Mitchell wrote about this: The Race Number lamps that seem to be on were white frosted glass lenses thus the on appearance. In other words the unit is probably not powered up.

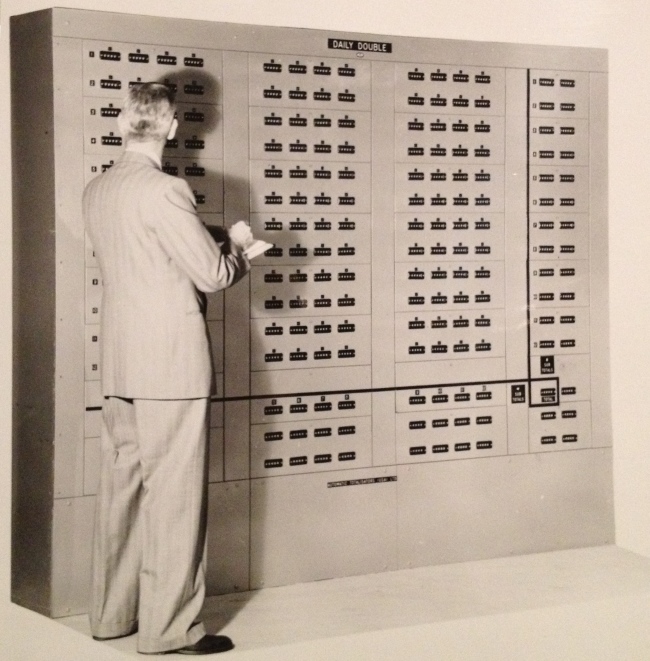

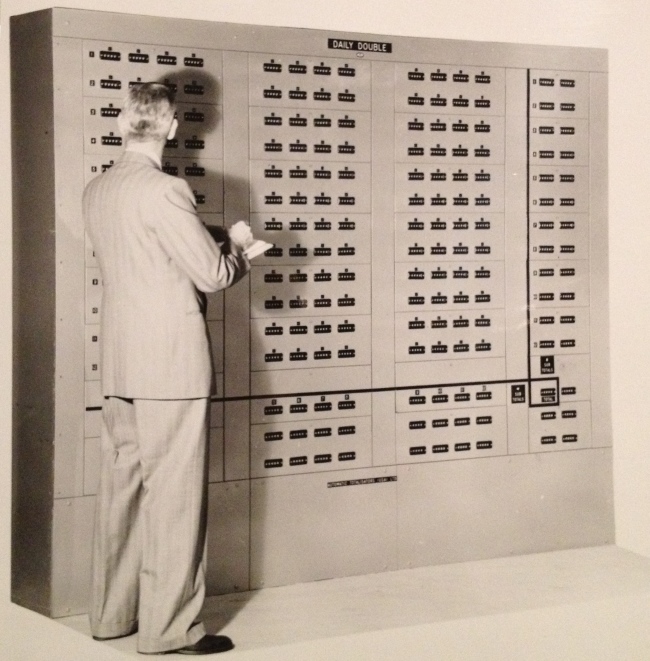

Counter Tote for Daily Double

Neville Mitchell wrote about the above photo: This photo is of Don Hardy and the RHJC Daily Double Counter Tote. The system used J10 issuers and typical counter tote relay control units i.e., Access, Multi impulse Routiner. Other counter totes were made for RHJC as the demand for "exotic" betting grew. In 1969 I installed a ex RHJC counter tote in Sabah. RHJC mentioned by Neville is the Royal Hong Kong Jockey Club as it was known when Hong Kong was a British Colony. The issuer Neville Refers to is a TIM (Ticket Issuing Machine)

The writing on the top of this rack clearly reads DAILY DOUBLE. The writing on the bottom of the rack reads AUTOMATIC TOTALISATORS IUSA LTD. Neville Mitchell wrote about the text on the bottom: The Automatic Totalisator IUSA name plate is a bit of a mystery. I can only suggest that at that time, late 1950's, AUTUSA was being established, and it could mean INCORPORATED? There was a lot of legal problems with setting up in USA due to what was called the "Sherman Act" which prevented monopolies existing or being formed. Neville mentions ATUSA which is the original name of Automatic Totalisators' subsidiary company in the United States and was an acronym for Automatic Totalisators United States of America. The company had a later name change to Autotote.

Don McKenzie wrote the following about the above image: It certainly looks like a counter tote recording system, meaning a system of small electronic counters as opposed to mechanical counters, but the only counter tote I worked on was a Win/Place system, one which I redesigned to speed it up by a factor of nearly 40. Don's modification of a counter tote is recorded above.

Neville Mitchell provided the following information on relays in the Julius Totes and the later telephone exchange era technology that was predominant in the Counter Totes:

ATL used many relay devices in the early tote machines the OVERLAP relays in the distributors were made to a Julius design, a very basic relay that would never falter in a long life as a integral part of the Julius electro mechanical totalizator.

In the 1960.s ATL began to use standard telephone equipment relays and stepping switches made to BPO standards and manufactured in Australia.

The ATL counter tote system for instance included 3000 type relays and TEI stepping switches, housed in "relay boxes" made by TEI.

Two types of general relays were in use the standard 3000 type and smaller 600 type. ATL would make a "E" sheet which described the construction of the relay, coils specification, contact pack assembly order and any other variation {i.e. slow to operate, quick release two windings etc.} then order the total requirement from TEI.

TEI uniselector's were used in many electromechanical tote systems. ATL would alter the standard TEI uniselector to perform functions such as count to 100 using two contact wipers in series on a 50 contact bank. Programmed uniselector's were used in devices that did routine checking of working counter tote systems.

ATL used American made relays made by CLARE they were crudely designed but robust in function the early DOUBLES totalisators used them in the control system as well as in the J10 doubles Ticket issuing machine.

Other companies also supplied relays to ATL, STC, AWA, Relays Pty Ltd, ES Rubin, Clare.

The demise of the BPO relay design began with the introduction of the German made mini pluggable relays in small plastic housings in only few forms, 2 , 4 or 6 change over contacts, one or two coils in voltages from 5 VDC to 250 VAC, one amp contacts were standard. This made the design of relay circuits much simpler as these economical relays allowed flexibility in design. These small relays were generally maintenance free, no cleaning of contaminated contacts, dust and corrosion free due to the sealed plastic housing.

{ A bit of history: The European made relays were never a quality problem, But they then decided to have them made in Mexico. This was a disaster, ATL delivered an infield lamp box indicator to the Royal Hong Kong Jockey complete with hundreds of the "Mexican" relays. Within weeks they started to fail mainly because the insulating material in the contact packs compressed thus loosening the spring contacts preventing any switching function. ATL had to replace all of these relays. All future orders s from RHKJC included a statement "No Mexican Relays"}!!

As Neville has mentioned TEI multiple times above, I will add TEI is a mnemonic for Telephone and Electrical Industries and had a large factory that stood near to the ATL factory in Meadowbank. ATL and TEI had a close relationship and there were people at ATL who had worked at TEI. Neville wrote the following about what he calls the ATL and TEI Association.

The ATL Tool Room was for a long time a prime supplier of machine tooling, jigs and fixtures to TEI. This included press tools, injection moulds. There was a period where TEI was tooling up to make the then new telephone exchange system using CROSS BAR Technology. These intricate switching devices transformed the old 600 type exchanges into much more efficient telephony, i.e subscriber trunk dialling.

ATL produced many dies and jigs for this TEI project. In 1965 ATL incorporated cross bars technology into two win and place tote mobiles that were used on the Melbourne Metropolitan tracks for many years.

In the late 1970's ATL was manufacturing dot matrix printers used in the J22 ticket machine. The small electro magnets that drove the dot print had to have a very strong magnetic force in a very small configuration. TEI had the only available magnetic iron suitable for the printer stator, problem was that this magnetic iron was not really machinable. The TEI stock was 12 mm round and ATL needed 6 mm round, the only way to do the reduction was by centre less grinding a slow and expensive process. Over the production life of the J22 terminal TEI, now Plessey provided the reduced material.

I recall the Redfern Mail Exchange project but I had nothing to do with it although I think ATL did make some components for TEI?

Howard Miller's reference to machining screws, reminded me of an incident involving TEI relays and the screws used to secure the armature onto the body of 3000 type relay. An airfreight shipment of Access relay sets to a race track in Canada arrived with all or the relay armatures floating free, the screws had all snapped of at the end of the thread that secured it to the relay body. Investigation revealed that the resonant vibration in the freight plane was enough to fracture the screw where there was a neatly scribed tool mark at the butt of the screw. Sort of provided a "tear across the dotted line" so to speak. Our staff had a lot of work to extract the broken thread out of the relay bodies.

As Neville has mentioned Howard Miller, Howard worked for TEI and remembers making parts for ATL. Following is an extract from the first email from Howard dated 30 March 2014, which is a good introduction:

I served my apprenticeship with Telephone and Electrical Industries at Meadowbank in the 1960's and left shortly after Plessey purchased T.E.I.. We also manufactured for Hoover and other small local firms. My brother also had an assembly job with this firm in 1965/66.

We manufactured parts for the Totalizer system as well as Redfern Mail Exchange mail sorting computers and for the military, back pack wireless sets. I worked in the Automatic lathe section, mostly making telephone relay armatures and screws in their hundreds of thousands.

Neville Also mentions secure the armature onto the body of 3000 type relay in his last quoted paragraph above. Following is Howard Miller's reply:

As it turns out one of my major machining tasks with TEI was the armature centre of those relays you mention. We made them in the tens of thousands on a Wickman 1 and 3/8 inch six spindle lathe.

TEI was perhaps the best employer of a forty year working life, although the wages were somewhat modest. Like ATL, TEI had its own lunch room and workers were not permitted off the premises during working hours.

Sadly little record of TEI exists at local council and on the Internet and it is a shame. I am very supportive of the effort made to record the existence of ATL and I do believe I have tooling made by the ATL toolroom in my possession. The challenge is finding it amongst the thousands of machine tools and parts I have collected. If I come across a marked item I will photograph the item and send you a copy.

Do you have any records of the many machines that were in the manufacturing section? My collection is automatic lathes, mainly BSA and Index Werke.

Since these initial contact exchanges in 2014, Neville Mitchell and his wife Nancy have become friends with Howard Miller and his wife Rosemary and Neville and Nancy have visited Howard and Rosemary in country NSW on two occasions and Neville wrote in April 2019 Howard and wife Rosemary are great friends with us including Liz.

Having mentioned ATL staff who had prior worked for TEI, the ex ATL Research Manager Phil White wrote the following, which is extracted from an email written on 31/1/19 in response to a Totalisator History website update notification relating newly included technical information on the old Julius Totalisators which were electromechanical: I love the old mechanical and electro mechanical. As I have said before I started in electronics at TEI just over the road from ATL (1966). It was uniselectors and crossbar equipment in the factory. I was working on the Redfern Mail Sorter and the first ever Timber Stress Machine. Loved going through the factory and hearing all the relays going clack clack.

Another very good friend of mine who worked for TEI prior to working for ATL is Bertha Schoder who Narelle and I see almost every time we visit Sydney.

In March 2019, Merv and Del Cathcart visited Narelle and I from Brisbane. Merv was the Assistant Chief Engineer of the Brisbane branch of Automatic Totalisators Limited during the Julius Tote era, the latter part thereof seeing the introduction of the Counter Totes. He also became the Assistant Chief Engineer of the branch during the computer based totalisator era and finally became Assistant Manager of the branch before retiring in 1997, after which he worked part time up until 2003. Merv remembers the Counter Totes at Woolloongabba seen in the image above titled A Counter Tote at The Gabba Greyhounds Brisbane. At the time of Merv and Del visiting us, it was just a couple of months more than forty years since these Counter Totes ceased operation. Merv informed me that there were only two counter totes used at the Gabba Greyhounds, the two shown in the image mentioned above, one for the Win Pool and the other for the Place Pool. He said these counter totes were mobile and were shared between the metropolitan tracks. He said there was an Automatic Totalisators Paper-tape Doubles Tote in operation at the Gabba and that there might have been a Paper-tape Quinella system as well. Merv thought the Odds Display Manual Control Console, the one with all the knobs on it underneath the TV monitor in the image above titled Equipment right hand side of a second Gabba Counter Tote, was for the Quinella Pool.