This is one of several pages relating to the history of the automatic totalisator, its invention in 1913, the inventor George Julius and the Australian company he founded in 1917 which became a monopoly and later part of an oligopoly, in this field. This page describes a shaft adder and provides information on the Julius Tote system at Ipswich in Queensland, to which it belonged. It ends with a glimpse at aviation, a subject of interest to Sir George Julius. This is a history only non commercial page. If you wish to start from the beginning then go to the index .

Copyright © 1997 Email - totehis@hotmail.com

| The Shaft Adder |

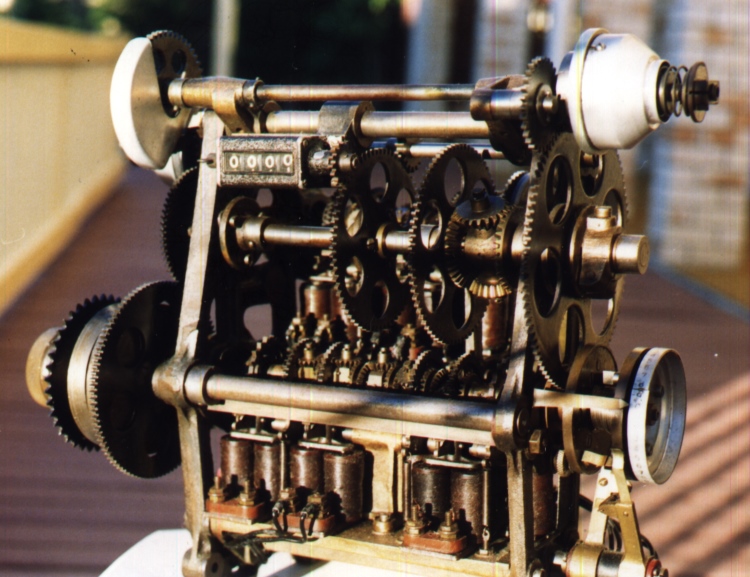

An Electro Mechanical Shaft Adder from Bundamba Racetrack

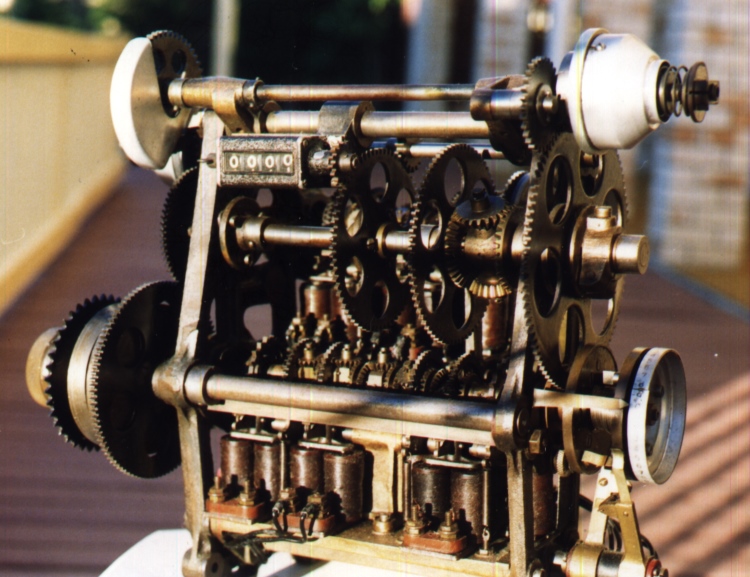

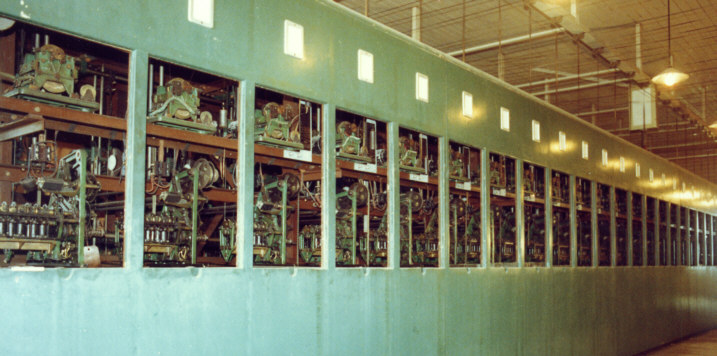

The shaft adder in the image above is one of many that have been restored and donated to museums and educational institutions. The adder weighs 26 Kg and was part of a win place totalisator system. There was one adder per runner in the race per pool. The complete system for a 24 runner field consisted of 50 adders 24 for the win pool 24 for the place pool and a grand total for win and place pools. The racks were constructed with 25 adders in a row for the win pool backing onto another row of 25 for the place pool. This made quite an impressive sight. The Place pool system shown below is two or three years older than the one at Ipswich, however as the Adders in the Ipswich system had been used in Mentone prior to being transferred to Ipswich, the adders are older than those seen in the image below. This image however gives a good impression of what the whole system looked like. There is a newer version of the shaft adder above in each of the windows in the Julius Totalisator Mainframe in the image below. Remember, the equipment visible in the image below is repeated on the far side of the frame for the Win pool.

These Julius Totalisators to which the shaft adders like the one above belonged, were behemoth machines. To put the adders into context, lets have a guick look at the system shown in the image below. The medium sized Julius Tote Mainframe shown below is taller than I am. Rather than looking at the size which is self evident, let's have a look at the mass involved. The shaft adder in the image above weighs 26Kg, and each adder in the mainframe below will have a similar weight. As mentioned above there are 50 adders in the sysem shown below and if each weighs approximately 26Kg we have a total of 1,300Kg. The most highly produced Julius Tote TIM was the J8 and these were the most common TIM attached to the mainframe below and were distributed around the track. Assuming the different models of TIMs attached to this system weighed approximately the same as the J8, which is 34Kg, then fully populated with the maximum number of TIMs the mainframe below could support that is 128, the TIMs would weigh approximately 4,352 Kg giving a total of 5,652 Kg. This does not include the fuse boards that are associated with each adder, the odds calculating and indicator drive systems that are also associated with each adder, the gear boxes, the indicators, the heavy main drive electric motors for each pool along with the associated drive shafts and pulleys, the reciprocating engine driven generator and its standby generator set that produced the 120V DC supply and other ancillary equipment as well as the miles of cable. Having mentioned the miles of cable, Jack Bell in his Miami Herald article describing the Hialeah Julius tote, wrote that the amount of cable in that Julius Tote system was calculated to be 195 miles! Jack's Miami Herald article can be read in the Automatic Totalisators In America chapter of this website under the subheading Hialeah Park's Australian totalizator, by selecting the Go to the index button in the Navigation Bar at the bottom of this page and then selecting the quoted chapter in the Secondly part of the Index. I well remember being very impressed by the large lead encased power grade cables, running up a wall inside the old Main Tote House at Eagle Farm Racecourse, rising high from ground level disappearing into the very high ceiling in excess of two normal stories to enter the Julius Tote Machine Room on the first floor, that connected the TIMs in all the Tote Houses on the track to the Distributors/Scanners in the front end system in the machine room. Another significant weight that is not included is the Julius Tote front end system, which is out of sight in the image below standing along the right hand wall, includes three tall racks containing the Distributors/Scanners with ancillary equipment which had its own drive motors, part of which can be seen in the image below titled A small section of the Distributor and Relay Switchboard at White City London. Also not included, standing with the three Distributor racks mentioned, are two additional racks of equipment containing what is collectively called the Machine Room Main Switchboard. As what has not been included in my weight calculation is assuredly heavier than what has, I feel confident to ask the question have you ever heard of a calculator/computer that weighs over 10 Megagrams? Well they used to be prolific around the planet, however they were also clandestine, hidden in machine rooms and tote houses, so it is no surprise if you haven't heard of them, but now you are on the road to find out.

Place Pool Julius Tote

A note about Charles Barton's dating of the shaft adder below. Charles was the last Chief Engineer to work with the Julius Tote at Bundamba racetrack near Ipswich from which these shaft adders were extracted. Charles maintained that these shaft adders were manufactured circa 1926. Charlie used to work in Victoria and knew the adders came from Mentone. Contradictory evidence indicates that these adders started operating in Mentone in 1936. Unfortunately, Charles is no longer living to discuss this further. The Julius tote at Mentone was preceded by a Lightning tote which used marbles to represent units of investment but this is not to be confused with the Hodsdon Marble Totes. If these adders were manufactured for the Mentone racetrack then it is logical to deduce that they were manufactured either in 1936 or just prior.

Circa 1947 (updated to 1950 by Rod Richards below) the adder was then used at the Ipswich Amateur Turf Club Queensland in conjunction with the custom made J6 and J7 model ticket issuing machines, until superseded in 1978 by a PDP11 digital computer based tote.

The adder registered either Win or Place bets on one horse only and could handle 4 units of different values on the rear shaft and 6 on the front shaft each controlled by a solenoid and an escapement wheel. e.g. 1 X 5 Pounds, 3 X 1 Pound, 2 X 10 shillings and 4 X 5 shillings.

The rate of sales, 72 per minute, was governed by variable speed rotary distributors, each with 16 TIMs ( Ticket Issuing Machines ) under its control and all on one particular value bank. Today these distributors would be called TDMs (Time Division Multiplexors).

A variable speed rotary distributor (scanner)

Selling on the 10 banks for the Win and 10 for the Place, or 20 bets registered at the same instant was no problem. Since there were 16 TIMs per scanner which sold Win or Place, this equates to 16 TIMs X 10 bets each X 72 RPM or 11,520 bets per minute per adder per pool.

Note - The computer staff are regularly reminded by the proponents of this technology that the computer totalisators cannot register multiple bets at the same instant. The computer systems record them sequentially albeit so fast that it appears to be instantaneous. The shaft adders could register multiple bets on a single horse at the same instant.

In the event of a drive failure such as a belt breaking, all adders were fitted with automatic cut outs to prevent loss of bet registrations. The configuration of the adders on a racetrack were back to back. One row of adders, one adder for each horse for the win pool, backing on to a similar row for the place pool. At the end of each row were the grand total adders with the associated winding gear for raising the vertical lift sliders on every horse adder.

The horizontal component was produced via the large chain sprocket wheel which let its slider out in accordance with the bets on that runner. This produced an angle between the vertical and the hypotenuse which was always related to perfect odds for that horse.

On this angle was a pulley arrangement which drove some cams operating a small motor which in turn powered the large barometer style odds ribbons situated on the face of the tote building.

An example of a barometer style indicator

Note - Neville Mitchell informs me that this indicator was in the paddock at Rosehill Sydney. The building is gone now, it was the main tote building with the machine room in the upstairs area.

For remote locations such as the centre of the racetrack or a loft, odds transmissions were achieved by the use of a variable resistance, mounted at the important angle mentioned and utilising the Wheatstone bridge principles. The remote receiver sensed any out of balance transmitted by the adder unit and drove itself and the odds display until the bridge centre leg potential was once again null and therefore equalling the transmitted odds.

Rising inflation and hence larger values being required, plus the need for exotic betting such as Doubles, Quinellas and Trifectas etc. made this machinery obsolete.

In addition to the shaft adder in the image, larger capacity adders, of 5 shafts for large racetracks, to single shaft adders for smaller applications, along with a highly developed modern miniature unit used in the mobile totalisators which serviced country racetracks for many years, were produced.

The basis of this revolutionary invention was the epicyclic bevel gear train designed by Sir George Julius. Such was the craftsmanship in manufacture that even after all those years of service 1926 - 1978, wear was minimal.

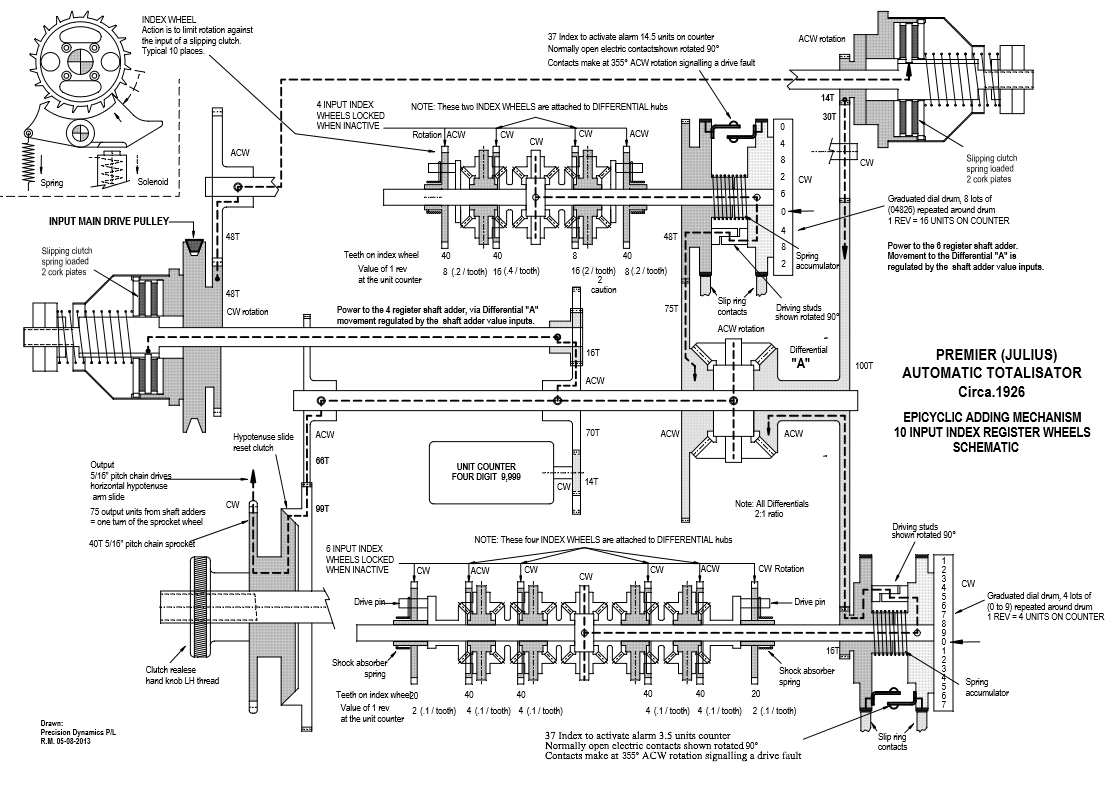

Bob Moran's Tote adder 10 register schematic

When I contemplate that I have a ridiculously obsessional interest in this subject, I look at work like this and other drawings like it that Bob has produced and I realise I am just a beginner.

Load a full screen image of a 3 Shaft Adder viewed from the escapement end. This adder had a capacity of up to 240 ticket issuing machines. The adder in the images above supported 128 ticket issuing machines. Groups of 16 ticket issuing machines were associated with each of the 8 solenoids in the adder. The 16 ticket issuing machines in each group were connected in suquence to its respective solenoid by an electromechanical time division multiplexer called a scanner.

The tote houses on display in the image above titled An example of a barometer style indicator and below titled The Old Main Tote at Randwick 1917, contained the machine rooms, which housed the frames, like the one in the second image on this page, which contained the shaft adders and other tote equipment, like the indicator display system. The ticket issuing machines were installed at the ground floor windows visible in these images and in other tote houses around the track. The two AJC notices that follow relate the operational procedures of 1917, being utilised on the newly installed Randwick Julius tote, inside the building shown in the image below. These procedures were in action and would have been on display inside this building at the time this photograph was taken. The system shown in the image below predates the invention of the odds calculating system used to drive the barometer indicators shown above titled An example of a barometer style indicator. Instead the system operating in the image below had the investments for each runner on display in the central section below the clock tower, in the three rows of fourteen counter windows spanning the width of the cnetral part of the building, as well as the pool grand total higher up on the tower below the clock.

The Old Main Tote at Randwick 1917

Part of the 1917 Julius Tote installation at Randwick is operating in the tote house in the image above. This system was the world's first electromechanical automatic totalisator system. It was the first of the large Julius tote systems and had 150 terminals. I think of it as the world's first large scale real time multi user system.

Notes on the following 1917 notices:

First see that ticket paper is correctly placed in the machine. Try one or more test tickets, noting that race number is correct and that sufficient ink is on machine (reserve all test tickets for manager). Close up all horse numbers on machine when window is closed. Await the hoisting of board showing final scratchings, then open up horse numbers shown. Be ready to issue tickets immediately window is opened.

Do not issue any tickets until instructed to do so by the ticket seller. Pay no attention to numbers called for by investors, the ticket seller will ask you for tickets required.

Should a ticket be issued through any cause and not sold, it must be handed to the Telephone Operator immediately the window is closed, with an explanation showing why it was issued, or otherwise the Ticket Issuer Operator will be held responsible.

Immediately the window is closed, remove paper from issuer, leaving two partly printed tickets on roll, and put on new paper for next race. Change race number and proceed as before.

Should issuer get out of order from any cause, turn switch off at once; the window should be closed immediately and signal given for Mechanic. On no account try to rectify same yourself; do not try to issue any more tickets until Mechanic has left cubicle.

DECEMBER, 1917.

Get cash from bank before first race. Get cash afterwards from banker or selling clerk as directed, giving I.O.U. for same.

When dividend is posted, work out dividends up to ten times and check same with next paying clerk, getting him to initial sheet, you initialling his.

Open up window when signal to pay is given, and keep it open until it is clear; on no account close the window too soon. Fill in list of tickets paid, and return all notes (retaining silver), tickets paid and list to banker, who will give receipt for same. Each ticket must be cancelled as it is paid. Carefully scrutinise ticket and check same with sample ticket given you before paying same, so as to avoid paying out on wrong tickets; as paying clerks will be held responsible for any mistakes made.

Should a legitimate doubt exist about tickets, ask the person tendering same to go to commission room or manager's room.

Should any ticket be presented which appears to be forgery or has been altered (use great discretion in doing this), obtain posession of same and ring the bell under counter, which will immediately bring a detective; then hand ticket to the detective, pointing out person who tendered same.

Should paying clerks be running short of change, pull out the sign for runner. Do not wait until change is exhausted; signal in time to prevent any stoppage in paying out.

DECEMBER, 1917.

Whilst on the subject of the 1917 Randwick Julius Totalisator, following is a Sydney Evening News article dated Saturday 15 September 1917 on Page 2, relating to the opening of this 1917 Julius Totalisator:

The Julius totalisator in the Saddling Paddock at Randwick will be in operation on September 19 (Derby Day), and should the wire needed for that in the St Leger Reserve arrive from America, as expected, the St Leger machine will also be working on that day. A trial of the paddock tote will be made at an early date to ensure proper working when ready for business.

It is interesting to note that the operation of the second machine was dependent on the delivery of wire from America. This 1917 Randwick Julius Tote installation consisted of three Julius tote systems.

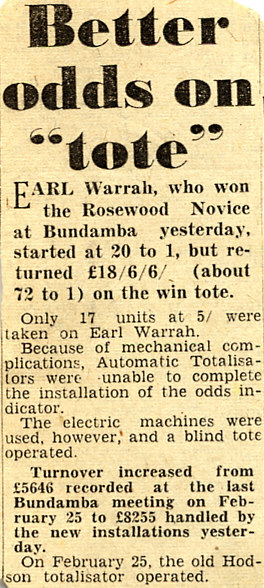

As mentioned above by Charles Barton, this adder moved to the Ipswich Turf Club at Bundamba, then known as the Ipswich Amateur Turf Club, after the operations at Mentone ceased. In November 2009 I was asked what year the Julius tote started operations at Bundamba. Charles Barton, last Chief Engineer of these systems suggests it was circa 1947. Shortly after this question I received an email from Rod Richards, an ex ATL engineer who had contacted me through this website regarding ATL. Although we previously engaged in significant email contact on this subject I did not realise until this, his latest email, that he had worked on the installation of the Julius tote at Bundamba. He knew exactly when the system opened in 1950 and even had a copy of the racebook from opening day. He sent me an image of the front cover of the racebook and a newspaper clipping relating to opening day. I have included Rod's images of the race book and article below. Rod had saved the racebook and newsclip for 60 years! Rod could not recall which paper the newsclip came from. I was two months old when this system opened!

The racebook image that Rod Richards sent me

The newsclip image that Rod Richards sent me

Note the problem with the display system. Some things never change! There always seems to be last minute hiccups with systems whether mechanical, electromechanical, electrical or electronic most of which are overcome by opening day and some slip through and are left for later rectification.

Additionally note the reference to "electric machines". I have heard the Julius tote at Eagle Farm racecourse referred to as the "electric tote".

Also note the mention of the Hodson Tote in the above article. This was a Marble Tote where marbles representing bets, were rolled down runner specific channels operating a counting gate at the bottom of the channel. I once read a brief description of this system, I think it was by Len Little who operated a manual Trifecta at the Brisbane Metropolitan racetracks when I started in Brisbane in 1978. As a result of this article I came to realise that computers are not the only machinery that has exception conditions and exception handlers. As part of this revelation I also realised that any real time system has events that inflict instant apprehension on the staff operating it. For the Marble Tote it was the bank up. Debris build up in the channels of the Marble Tote could cause a condition termed a bank up where marbles would be blocked from rolling all the way down the channel. When this occurred it fell upon the "Marble Boys" to scurry down the channels, identify the cause of the bankup and clear it to the best of their ability in a fashion that did not cause an avalanche of marbles. This was not always possible and there were times when an avalanche occurred causing a mass of marbles to arrive at the counting gate, a condition that would often result in marbles jumping out of the channel and rolling around the counting room floor with bewildered operators picking them up and scratching their heads wondering where they came from.

On the subject of any real time system having events that inflict instant apprehension on the staff operating it I had a favourite in the PDP11 period. This actually touches on another subject of the significance of sound with the Julius Tote, which the engineers working on them could use to determine the health of the systems and often identify a faulty part. A system crash with the PDP11s produced a crash dump with some of the information being sent to the console terminal. This included the contents of the general purpose registers, contents of other pertinent processor and peripheral registers and the contents of the stack. This resulted in many short lines with many carriage returns and line feeds on the hard copy Teletype making a staccato sound which you immediately recognised and had no need to go and read what was being typed announcing that your day had just taken a step for the worst.

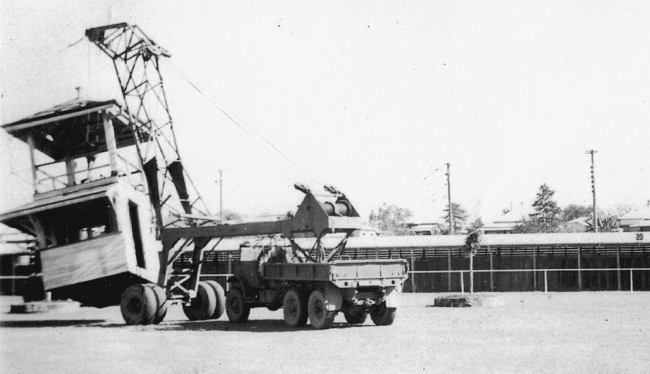

Rod has since sent other emails providing more information on the Ipswich Julius Tote installation. I have omitted the second of the images Rod refers to in this text. It shows the indicator being constructed and this indicator is clearly visible in the third photo, the indicator running at right angles to the tote building. The shaft adder in the image at the top of this page was operating as part of the Julius tote inside the tote building shown in the image below at the time this opening day photo was taken.

Rod's image of the Julius tote house being constructed at Ipswich reminds me of an observation of a possible relationship between George’s two companies. Since the advent of microprocessors and more compact computer hardware totalisators have been easily accommodated in existing buildings. In the Julius tote era, tote houses were custom built to house the tote machinery. Another probable reason for the construction of new tote houses is that in this distant past racetracks had less infrastructure to house the new machinery. The Old Main tote building at Randwick, displayed multiple images above, is another example of a custom built Julius tote house. Charles Norrie suggests in his talk to the Computer Conservation Society at the London Science Museum in 1993, that George Julius’ two companies, Automatic Totalisators Limited and Julius Poole and Gibson had a synergistic relationship with the former selling totalisator systems and the latter designing and overseeing the construction of the buildings to house them. An extract from an edited transcript of this talk follows:

Anecdotal evidence from Julius' son Audrey, who was the one son to go into Julius Poole & Gibson, suggests that though the totalisator was a separate venture from Julius' engineering consultancy, the latter benefited from the orders for buildings at racecourses. Julius' firm's order book suggests also that this was so.There is a link in the links section of this site to the complete edited transcript of Charles’ speech.

Go back to the index

Go back to the index

Go to the bottom of the page

Go to the bottom of the page

I still have some vivid memories of the Bundamba installations and of Ipswich as this was my first Totalisator installation and trip away from the Meadowbank factory.

With the Bundamba installation, I recall it was all stops out with a couple of all nighters thrown in to get to open on time, but the indicators had to suffer, does this sound familiar to you? The problem was mainly due to the various equipment arriving in time at Bundamba by road transport from Sydney, which in those days were ex WW2 semi's, which we thought would never get to us and put us way behind schedule.

It might be of interest to see the attached photo's, these are some that I took during the installation of the Totalisator in May/June 1950. I am sorry about the poor quality of the photo's as they are nearly 60 years old and I had to re photograph the originals so that I could email them.

In photo 1, it shows the Tote house under construction in May 1950, the chap in the foreground in shorts and singlet is Bob O'Leary, the Tote Engineer in charge of the Totalisator installation at Bundamba. Bob and I did much of the early ground work in installing the Totalisator right up to the start of operations and in the future running of the machine. Frank Ryan was the Chief Engineer for Queensland at the time; Bob reported to Frank Ryan during the installation.

Webmaster's Note:

As I recall, I met Frank Ryan briefly as he popped in to see what was happening at the racetracks a long time ago. I think Charlie Barton, mentioned previously, was still working with us at the time. Charlie Barton was Frank Ryan's successor. I inherited a manual that belonged to Frank, as I was regarded as a company historian at the time and historical items seemed to land on my desk. I think the manual contained technical information on an Automatic Totalisators Limited product called Visitel. It allowed writing on the top of a local machine to be transmitted to a remote one by mechanically sensing the movement of the pencil. ATL made these wonderful custom versions of manuals and this one was dedicated to Frank Ryan.

Photo 1 Julius Tote House under construction

Photo 2. The Indicator Enclosure under construction.

The Indicators were one of the problems with the installation as we were not able to have them completed in time for the opening.

Webmaster's note:

As mentioned I have omitted this photo, due to the low resolution. The completed indicator can be seen in Photo 3 below. It is perpendicular to the Main Tote House and extending from a position near the centre of the tote house. From Photo 3 it is possible to ascertain from the runner numbers and pool names painted on the indicator that this Julius Tote supported a maximum of 20 runners in a race as well as two pools, Win and Place.

Photo 3. The grand opening of the Automatic Totalisator on Race Day 3rd June 1950

Photos 4 and 5:

Just one other thing that you may have knowledge of, was the "Magic Eye" camera, or photo finish camera. This version was developed by ATL around 1949 and was used for the first time at Bundamba. The camera was located in a specially built enclosure above the Judges Box and operated by ATL staff; I did operate the camera at times. In operation each finish was taken and if the judges called for a photo, the image was taken from the camera, which had developed the film, and dropped down a chute to the judges.

Webmaster's Note:

Yes I do remember the photo finish cameras. When I started work on the Queensland racecourses in 1978, the Brisbane Branch of Automatic Totalisators Limited was still maintaining the Photo Finish systems.Photo 4. The Magic Eye enclosure and the Judges Box under construction.

Photos 4 and 5:

I remember the Magic Eye camera being developed at the factory by a serious dark haired chap and the rumour has it that he was a Spitfire pilot in WW2 and was developing the camera for ATL based on the gun camera in the aircraft, of course this caught my attention, but how much truth is in the story I do not know, but I still wonder what did happen to the Magic Eye camera at Bundamba and did it develop into other installations. Check out the fashions of the racegoers of the day!

Webmaster's Note:

I had heard the name Magic Eye Camera, however this system was commonly referred to as the Photo Finish Camera during my time. Rod's comment about the fashions refers to image 5 below.Photo 5. The Magic Eye enclosure and the Judges Box on race day.

Webmaster's Note continued:

I think photo 6 below is particularly interesting. Rod previously mentioned the ex WW2 (World War 2) Semis. This too looks like some ex WW2 rig, which the RAE would have put to good use if it was one of theirs. It is interesting how, what looks like a 20 ton truck has had a substantial crane attached to it. It looks like the crane might be detachable making it a very versatile arrangement. It is additionally interesting that the old Judges box has been removed in one piece rather than being dismantled providing the possibility of reusing some of the wood. I wonder what happened to this old Judges Box, whether it was relocated in one piece for use elsewhere, possibly for some other purpose, or just dismantled somewhere else.

Photo 6. The Old Judges Box being removed.

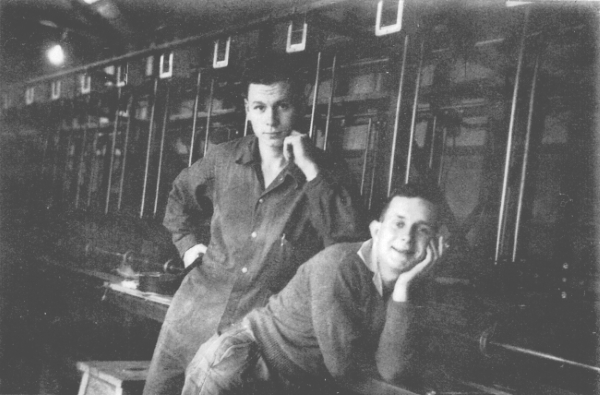

Photo 7:

Assembling the Totalisator inside the Totalisator building. On the left is Rodney Richards, an 18 year old apprentice and Bob O'Leary, engineer in charge.

Webmaster's Note:

The image below showing Rod and Bob, shows an early stage of installation of one of the Automatic Totalisators Limited Julius Tote mainframes at Ipswich/Bundamba. From memory, this was one of two mainframes at Ipswich. What I saw in 1978 is 28 years after this system was installed so changes could well have taken place in between. Have a look at the second image in this page to get an impression of what the system in the image below looked like when it was completed. Remember that the Ipswich system contained the adder shown in the first image of this page, so if you can, imagine the adder at the top of this page replacing all the adders actually in the frame in the second image in this page, you will have a good idea of what it looked like. To complete this mental picture, when I first saw the Julius tote at Bundamba, the mainframes had no cladding on them. This could have been the original state of this system as there have been Julius tote mainframe installations without the cladding. In other words it looked like the mainframe in photo 7 below, except it had all the equipment installed.From what I can see, none of the shaft adders have been installed in the frame yet. The tall white oblong rectangles along the top of the frame are the runner number windows. They look empty in the photo and these, on completion will contain illuminated runner numbers in them to identify which runner number the equipment at their respective locations is associated with. They also indicate which Adders and their associated odds calculators are participating in a race, as the equipment associated with a non runner will have its associated runner number light extinguished.

The pairs of parallel vertical rods, below the row of white rectangles, can easily be seen and are the transport mechanism for the vertical sliders, which represent the pool grand total in the odds calculation system. The darkness of this image makes it impossible to ascertain whether the horizontal transport rods are in place, which support the horizontal sliders, which represent the investment on each runner. To the right of Bob's hand he is resting his head on, are two arms forming what looks like a dark X. These are two of the many hypotenuse arms. These arms are independent of each other. There is a hypotenuse arm for every possible runner in a race, 20 in this case, which is duplicated 20 for the Win pool and another 20 for the Place pool. Having come to a total figure of 40, I will take this opportunity to mention that there are 40 adders yet to be installed, one for each odds calculating triangle with an additional two grand total adders, one each for the Win and Place pools. These grand total counters will control all the vertical sliders for their respective pools.

Back to the odds calculating triangles. These hypotenuse arms connect each of the vertical sliders with its respective horizontal slider forming right angled triangles, one for each runner in each pool giving the total of 40 in the case of this installation. Each horizontal slider is controlled by its associated runner specific adder. In the image below, the hypotenuse arm in the dark X shape previously mentioned, with a negative gradient forms an angle with the vertical slider on the near side of the frame, which represents the odd for its associated runner for one of the two pools. As it is not possible to determine from the photograph which pool is supported on which side of the frame, for the purpose of this description let's assume the near side equipment belongs to the Win pool. The arm with a positive gradient then represents the odd for its associated runner in the Place pool on the far side of the frame.

A drive shaft with drive pulleys on it can be seen running across the top of the bench that Bob O'Leary is leaning on. Each of the pulleys on this shaft will provide drive motion for each of the shaft adders which will sit above the shaft when they are installed. Between the vertical sliders seen on the near side of the frame, looking through the mainframe to the opposite side of it, the vertical sliders associated with the equipment on the opposite side of the frame, as mentioned in the previous paragraph, can be seen.

Photo 7. The Julius Tote Mainframe being installed.

Webmaster's Note continued:

Rod and Bob are presenting a rather relaxed look in the image above, which I can only think is for the benefit of the photograph, considering the amount of work left to do! Tote installations very very rarely accommodate any opportunity to relax. Having mentioned this, the following aviation segment has an example of a rather rebellious relaxing weekend during one of the most intense and gruelling installations.Neville Mitchell, the best Automatic Totalisators Limited historian I know, wrote the following comments about Rod's description of the Ipswich Julius Tote installation:Rod also has a photo of the Racehorse Hotel which he writes is near the entrance to the racecourse and across the main road from the Mines Rescue Station and was a popular spot for lunch. I too have been a patron at this hotel a few times in the decades that I worked at this track. Rod also has a photo of Tote Engineer Jack Nolan at Cloudlands Ballroom taken on 16/10/1950 when he was visiting Bundamba and Brisbane. Rod also wrote that Cloudlands was a very popular spot in those days.

Had a good read of Rods story, it certainly was typical of all installations both Electro mechanical and Electronic, long days and overnights were the norm.The photo of the happy apprentice and the engineer in charge, reminded me of tales I was told of the old days in Melbourne, where apprentices were only allowed in the machine room providing they had and kept their hands in their pockets. They were terrified of the chief engineers.

Round the clock working was often the way production met delivery dates. Three shifts were worked during the 1960s. I did a few all-nighters with George Klemmer, Peter Rolls and Terry McCauley, about the time of development of the Aqueduct projects J11 and the Analogue Odds Computer. Iris the lady who ran the Company canteen would cook us up a huge breakfast at seven in the mornings. Ah all so long ago now!

We have had a few pilots in ATL that I am aware of, Rod Richards is one of them and we have had some email interaction on this subject. Alan Rose is another, who was an ATL engineer and project manager and is mentioned on other pages in this site. David Hamilton, who was ATL Operations Manager for New South Wales, was a Navy Pilot. He has flown some iconic aircraft like the Supermarine Seafire through to jet aircraft and he has very interesting aviation anecdotes relating to the difficulties of landing on an aircraft carrier. David has written his tote memoirs on this website in the Memoires of an Ops Manager and Harold Park chapter. To read this, select the Go to the index link in the nav bar at the bottom of the page and select the chapter. Norm Lee, was an ATL Operations Engineering Manager and also an aviator. George Julius' son Roderick was an aviator and he is mentioned below. And then there is myself. I too am in this fraternity. Following is a brief observation of technological change with a mention of aviation.

This website is an observation of technological change. The tote was transformed after half a century of electro-mechanical computing to a digital computer application. Many other transformations have also taken place during this transition.

In the early 1990s the totalisator history saga was being preserved by cleaning up shaft adders like the one in the image at the top of this page and donating them to museums and educational institutions. These donations were being arranged by writing and reading letters (snail mail). By the late 1990s the story was being told by this website and related communication was by Email. The following paragraph is an extract from an article written for a Tabcorp company magazine called On Track in January 2007.

Today in the era of mobile phones, when people are in contact all the time, it seems archaic to envisage a time when there were no mobile phones let alone contemplate having no phone at all. This was the case when the new computer system started, in the late 1970s, as it was illegal to have any telephone on course.As mentioned elsewhere on this website relating to the Brisbane Project the electro-mechanical Julius tote systems were replaced by digital computer based totalisators manufactured by Automatic Totalisators, the same company that manufactured the Julius totes. When the Brisbane Project, which developed the PDP11 based tote systems to replace the electromechanical Julius totes in Brisbane, entered the installation phase, there was a permanent contingent of the Systems Dapartment on site at the tracks in Brisbane. As this project was running behind time development work continued on this system in Brisbane. Massive amounts of overtime were being worked and finally the members on site decided they needed a week end off. The following is an extract from an article I wrote for a company magazine called On Track in May 2006:I recall many occasions of having to leave Eagle Farm racetrack, one of 5 this system serviced, and walk down Racecourse Road to a public phone box to make a phone call. This phone box started out as one of the red wooden types, not unlike Dr Who’s TARDIS, then was upgraded to an aluminium and glass one and then like Dr Who’s TARDIS totally disappeared only to reappear transformed again in another location and time.

When we used to be at the racetrack late at night, trying to rectify an end of session procedure which had gone wrong, or repairing a system so it would be available to run the next meeting, it was not possible to quickly ring home to say that we were still alive and well. As we were locked inside the tracks and we were not entrusted with keys, entering and exiting the tracks required climbing fences so it was easier not to call.

One night the wife of one of our technicians had enough of the anxious waiting for him to come home and rang the police. They arrived at the trotting track and awoke the racecourse manager there. This caused a significant political issue between ATL and the Club management. ATL management took a dim view of the phone call however I felt that she had made a good point. This sort of thing evidently was nothing new. Charlie Barton who was the Chief Engineer of the electromechanical systems in Brisbane, had a term for wives of tote engineers, he called them tote widows.

Cirrus on final, Runway 28R ArcherfieldThe project team about to leave Rockhampton

The on-site project team came to me one day, prior to the commencement of operations of the new system and asked if I would fly them to Rockhampton and Keppel Island, for a well deserved week end off. After ascertaining the availability of a suitable aircraft I replied in the affirmative.

When the Project Manager was informed he replied that a weekend off for everyone was out of the question. The team insisted that they desperately needed a break and eventually convinced him that the increased productivity resulting from the break would be worthwhile.

So it was that we found ourselves on a Friday night on a left downwind to runway 15 in an Aztec F admiring the lights of Rockhampton below. The time on the beach at Great Keppel Island was truly therapeutic. The project manager mentioned above, left Automatic Totalisators after this project and joined the Victorian TAB as Computer Systems Development Manager. He later became a Vice President of United Tote. He is an excellent totalisator historian.

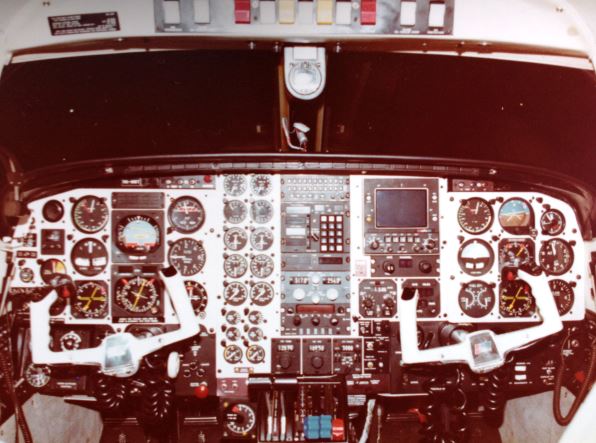

To put technological change into perspective it is hard to believe that my grandparents could remember a time without any radio or aeroplanes. There is quite dramatic evidence of this change in aviation. In the two photographs above, the Aztec had the classic mechanical instrumentation found in all aircraft of its time. The Cirrus, a new generation aircraft, on the other hand has a "glass cockpit" where the traditional mechanical instruments are replaced by CRT or LCD screens which resemble a video game. The engine page of the MFD (Multi Function Display) is visible in the centre of the picture. The PFD (Primary Flight Display) is on the left and hidden by myself and the seat back. The mechanical instruments on the right are backup instruments. These impart a warm fuzzy feeling inside to those pilots familiar with the way it was and those skeptical of the reliability of electronics and those who have nightmares about losing a whole category of instrumentation in a single failure.

Since I put the above aviation images on the Internet it has occurred to me that there is a problem with my presentation. I have placed an image of a light aircraft glass instrument panel as it is new and unusual. As time passes however, this glass panel will become the norm and readers will ask what it was like prior. To rectify this problem I have added the following additional image that is an example of a classic instrument panel. This aircraft is the only gas turbine engined aircraft I have flown.

Piper Cheyenne classic instrument panel.

What does this have to do with totalisator history I perceive you ask? Well apart from the Automatic Totalisators on-site crew going on a flying week end and an observation of another significant technological change, George Julius, the inventor of the world's first automatic totalisator, was interested in Aviation. George was the Chairman of the Australian Council for Aeronautics.

George's son Roderick was a pilot. Roderick installed a Julius tote in the USA. He flew around Australia in a Taylor Cub aircraft. He also owned a Taylor Cub along with Clarence Stumbles. They were both directors of Wings Pty Ltd. Roderick was interested in multiple avaition ventures. He intended to partake in an air pageant at Orange and was tragically killed in an aircraft accident at Narrow Neck in the Megalong valley, whilst travelling to Orange. Sadly this accident seems to be a classic example of an aviation accident syndrome called get-home-itis or get-there-itis which is akin to Mission Mania.

In June 2017, Rod Richards sent me an email in which he wrote the following:

I had a nostalgia attack watching this film of the Piper Cub which handles and flies very much like our Luton Major, see attachments – you could almost say an English version of the Cub. Glen and I have had many pleasant hours in the Luton.I informed Rod that it was ironic that he mentioned the Piper Cub as Roderick Julius had died in one and that Roderick had flown around Australia in a Taylor Cub the year before in 1937 with J.C. Clancy. I mentioned that I thought Roderick was an agent for the Taylor Cub aircraft. Following is an extract from Rod's reply:

I looked up Taylor Cub https://en.wikipedia.org/wiki/Taylor_Cub and read the connection between Taylor and Piper, which you may find interesting. Roderick could have possibly been the agent for Taylor/Piper here in Australia in the 1930’s.I have since noticed that the Kings Candlesticks website states that Roderick and Clarence's company Wings Pty Ltd had the agancy for Taylor Cub aircraft. I have also read in a Trove newspaper article with the following details: 1939 'SIR G. JULIUS'S SON A VICTIM.', The Sydney Morning Herald (NSW : 1842 - 1954), 31 January, p. 11. , viewed 17 Jun 2017, http://nla.gov.au/nla.news-article17544832 that Mr. Julius was managing director of Julius and Gardiner Pty. Ltd., manufacturers' representatives and agents in Australia for Cub Aircraft. He was a pilot of considerable experience with hundreds of flying hours to his credit.Also, interesting that Roderick flew around Australia with J. Clancy, this, I think would have been Jack Clancy who with his brothers designed and built the Clancy Skybaby in 1931, a single seat light aircraft. There is a Skybaby in the Aviation Museum Bankstown. If you go to the website www.aamb.com.au there is a write up of the Clancy brothers.

The Clancy Skybaby was one of the approved designs, we could have built when we selected the Luton Major to build.

It’s amazing how the connections with ATL keep cropping up, due to your wonderful research.

Additionally, relating to Rod's email, I have read in another Trove newspaper article with the following details: 1939 'FLEW INTO FOG TO DEATH', The Sun (Sydney, NSW : 1910 - 1954), 31 January, p. 3. (LATE FINAL EXTRA), viewed 17 Jun 2017, http://nla.gov.au/nla.news-article229476941 which relates to the accident in which Roderick Julius died, something that confirms Rod's thought that J.C. Clancy who flew around Australia with Roderick Julius, was Jack Clancy. Following is the relevant article extract: Mr. Jack Clancy, who flew round Australia with Julius in one of these machines, said: "The Tavlor Cub is a safe plane, and even a forced landing would not have killed them, as its landing speed is only 27 miles an hour."

Recently I was informed that Churchill Julius, George's father had his first flight with Francis Chichester. I was sent a copy of a photograph titled Archbishop Julius and Ada made their first flights with Mr Francis C. Chichester (later Sir Francis) at Wigram Aerodrome in May 1930. Francis Chichester was the first pilot to land at Lord Howe and Norfolk islands, two locations I have many fond memories flying to.

I have exchanged many emails on the subject of aviation with Dermot Elworthy, George's great nephew who is a retired pilot. In 2010, Narelle and I met him in Little Venice in London at a meeting to determine if a George Julius society should be established. In 2016, Narelle and I spent some wonderful days together with Dermot and his wife Sandy in Wells.

Let's not forget that ATL used to manufacture parts for the iconic Australian aircraft the Victa Air Tourer. This had to comply with the demanding airworthiness requirements. This project pre-dated my time with ATL as I started in 1977. Neville Mitchell remembers Air Tourer parts production at the Meadowbank Factory.

And then there was this! Narelle was reading a book which I am looking forward to reading after she has finished, called My God Its A Woman written by Nancy Bird Walton, a famous Australian aviation pioneer. She wrote about the first time the Singapore to Australia air route became available. A new company was formed to fly this route called Qantas Empire Airways. This company was owned forty nine percent by Queensland And Northern Territory Aerial Services (QANTAS), forty nine percent by Imperial Airways and had a two percent ownership arbitrator. The name of this arbitrator? You guessed it. Sir George Julius!

Years after the above paragraph was added to this page, a long time after I read Nancy's interesting book, I received an email in May 2017 from Frank Matthews, who was the last senior partner of George Julius' engineering consulting company Julius Poole and Gibson. Amongst other things, Frank mentioned that George had been an arbitrator between Qantas and Imperial Airways, as he thought I might not have known about this. Indeed, I would not have known about it except for Narelle's happening to read about it in Nancy Bird Walton's book. I informed Frank that I had already recorded this on the Totalisator History website and I provided him with the URL of this page and directed him to the paragraph above. On reading this, Frank then replied with the following comment:

And now I have an explanation for the discovery of George Julius' connection with Qantas. I had only learned this from my younger sister Doreen who lives in Brisbane but I never got around to asking her how she knew this. She was a pilot and good friend of Nancy Bird Walton with whom she participated in women's round Australia air races. Probably Doreen would have read the same book and subsequently mentioned it to me.In the information Frank originally sent, I did learn that Qantas and Imperial Airlines never had a situation requiring recourse to George Julius.

Another matter Frank wrote about informed me that Julius Poole and Gibson had worked on the Luna Park project. As Luna Park is a Sydney icon like the Opera House, it piqued my interest. Frank wrote the following about Roger Gibson who worked on the Luna Park project:

Roger was a creative mechanical engineer, who was thrown jobs requiring imagination and ingenuity like Luna Park where he was responsible for concept and design of much of their amusement equipment.Frank gave me a reference to this in the book Julius Poole & Gibson The First Eighty Years. I knew Julius Poole and Gibson had worked on the Qantas maintenance hangar, however on reading the pages suggested by Frank, I discovered Roger was responsible for the Qantas hangar project. I have included the following information here as the Qantas hangar project is yet another link between George Julius and aviation. Following is the section of the book containing Frank's suggested reading, which bears the title Roger Barraclough Gibson. Roger was the son of one of the original partners of Julius Poole & Gibson, Alexander Gibson:

Roger Gibson, son of Alexander, was born in Sydney in 1909. Educated at Shore College and Sydney University, he graduated B.E. in mechanical engineering.I too worked at the Sydney Opera House. I worked on the installation and commissioning of the electro-acoustic and CCTV systems for AWA, a large iconic Australian technology company. AWA was a subcontractor to Julius Poole &Gibson. I remember Roger's acoustic clouds well. I too was at the opening ceremony of the Sydney Opera House.Roger is remembered for his great sense of humour which some of the firm's old guard considered irreconcilable with the profession of engineering. However, no-one was prepared to dispute the "old man's" wishes and so Roger joined the firm in 1937.

Prior to World War II Roger was mainly employed on experimental work studying the discharge capacity of Burrinjuck Dam, using a hydraulic model built at the Sydney Technical College.

In 1941 Roger joined the Australian Army, serving in the Middle East with the Australian Ordnance Forward Company Workshop. A story demonstrating his characteristic good humour is told of his return to barracks late one night after a hilarious celebration between battles.

Being uncertain of his exact whereabouts he asked a sentry for directions to Captain Gibson's quarters.

"But are you not Captain Gibson, Sir?"From the Middle East, Roger was transferred to New Guinea where he served from 1943 to 1945, rising to the rank of major."I don't give a damn who I am but please show me where Captain Gibson hangs out" was the reply.

Suffering a long bout of ill-health after the War, he rejoined Julius Poole & Gibson and worked on design projects requiring considerable originality. Because of his ability as an imaginative and clever engineer, he was often approached by the legal profession to act as an expert witness. He quite relished this kind of work.

Roger was heavily engaged with Joe Fry on N.Z. Forest Products valuations which were required to be updated every year for earthquake insurance purposes. Other projects Roger worked on included design on coke ovens and conveyor systems for the Mount Pleasant and Illawarra Collieries, the design and development of aircraft support carriages for Qantas maintenance hangars, power-operated hangar doors at Mascot and cargo handling equipment for Qantas' first air cargo terminal.

He was highly regarded by the management of Luna Park for whom he adapted and tested mechanical designs for amusement equipment over a long period of time.

One of the last projects Roger worked on was the detailed design of special mechanical devices and winching systems for the Sydney Opera House. These included glass wall cleaning gantries, winch systems for TV light battens, loudspeakers, and acoustic cloud reflectors in the Concert Hall.

Just as well his war injuries kept him awake the night before the Opera House was opened by the Queen. On a hunch he went to the site in time to repair leads to the amplification system which had been cut by a vandal. Roger Gibson was made an associate of the firm in 1958. He retired in 1975 and died early in 1978.

| Acknowledgements |

| Previous page | Go to the index | Top of the page | Next page |