| This is one of several pages relating to totalisator history, the invention of the world's first automatic totalisator in 1913 by George Julius and its subsequent development. This page is a study of the Julius Tote installed at the Harringay Dog track in London. |

The Harringay London Julius Tote

|

Postscript - It is now June 2005 and I have just received mail from Caracas. I was informed that the Julius tote there is still in operation. After 48 years of operation I have been asked if I have any information on how to make adjustments to the system to bring it up-to-date! This view of the Julius totalisator differs from others in these pages in that it is a relatively contemporary view. Computers were in everyday use when this was written. I have often contemplated analogies between these electro mechanical systems and computers. One piece of equipment mentioned in this article is a commutator, also called a scanner in another section of these pages, which I have likened to a serial line multiplexer. I have often thought that another analogy to the function of this device is polling and I note that Charles Norrie has also used this analogy in his article. I often found it curious that the Julius tote at Eagle Farm supported sixteen terminals per scanner and that our ATL digital communications protocol used in the PDP11 computer system that replaced the Julius system polled up to sixteen terminals per line! Postscript: What eventually dawned on me was that there is a contemporary term I am well acquainted with, that perfectly describes these scanners, which are also called distributors by certain contributors to these pages who worked on the Julius Totes. It is Time Division Multiplexer or TDM, and these scanners existed long before the advent of the electronic digital signalling methods that made this term commonplace. |

| Harringay Greyhound Stadium Totalisator and George Alfred Julius |

|---|

| The following article is reproduced courtesy of GLIAS (The Greater London Industrial Archaeology Society) a registered charity devoted to recording and explaining London's fast disappearing industrial history. It is written by Charles Norrie and photographs taken by Dr. Robert Carr. It is extracted from the GLIAS magazine London's Industrial Archaeology No. 5. |

|

With Tannoy loudspeakers and a strongly period atmosphere, the little

Harringay Greyhound Stadium seemed sadly on its way out, and in fact was

shortly to close. More popular dog tracks were going in for lots of shiny

restaurants and champagne - Harringay had beer and hot potatoes and, but a

modest enclosure for the "nobs". A small party from GLIAS joined the tiny

crowd of mainly older people, quiet and orderly, at an evening meeting on

Monday 16 March 1987. Dogs, mechanical hare and the starting traps were

all of great interest and could be inspected at close quarters, but the

main attraction was the Julius patent totalisator, the subject of this

article, and now, alas, along with the stadium, no more. Before the track

closed in September 1987 we made several visits to record the totalisator,

installed in 1930, and electromechanical machine of intriguing design used

to operate the tote, and in use throughout virtually all the life of the

course.

The tote is a form of betting which pits the bet of an individual against the collected bets of all others, and hence differs from fixed odds in which the individual bet is against the opinion of a bookmaker. Simple as the concept is, designing a method for operating a tote effectively within the constraints of the numbers attending a race course and the frequency of races is demanding. In a series of patents in the first 40 years of this century (Note 20th century), the Australian inventor George Julius designed a number of machines that made large scale tote betting feasible, accurate and rapid. In the United Kingdom Julius's machinery, supplied by Automatic Totalisators, was applied to greyhound racing, a sport introduced from America in the 1920s. The machinery at Harringay reflects Julius's 1920s patents but not those from the '30s, and such modernisation as there was (notably in the odds calculation and display machinery) was entirely different. George Alfred Julius, knighted in 1929, was born in Norwich, England, in 1873 and was taken by his parents to Ballarat, Australia, in 1884, his father securing the position of archdeacon there (1). In 1890 the family moved to Christchurch, New Zealand, and here Julius obtained a BSc in mechanical engineering at Canterbury College in 1896. That year he was employed as an assistant engineer on Western Australian railways, and in 1907 moved to Sydney, as an engineering consultant, but with the right of private practice. His first UK patent (confusingly still giving his location as New Zealand) for counting machinery (2) was to be followed by nearly 20 others stretching through to the early 1940s, which progressively improved and augmented his original invention, finding practical application in automating the tote at Australian horse race courses. The major intention of these patents was to permit an increase in the rate at which bets could be placed, improve the display of betting information and increase the security of the apparatus. The first machine was installed at Ellerslie Racecourse in Auckland, New Zealand, in 1913, and an improved apparatus was then extensively employed in Australia. By 1930, virtually all the elements comprising the equipment at Harringay had been invented. His totalisator work was a sideline for Julius, and he had a wide ranging career in Australian government and engineering, advising on subjects as diverse as prickly pear, the break of railway gauge and water resource development. He became the first chairman on the Council for Scientific and Industrial Research, as well as leading several professional engineering organisation. He died in 1946. In the UK the introduction of Julius's totalisator followed the arrival of greyhound racing from the United States in the 1920s, and required the modification of betting law. Proponents of tote betting considered that mechanisation removed many of the moral objections to bookmaking. The Treasury, recognising that a mechanical system would make the levy of the recently introduced and unpopular betting tax convenient and feasible, amended the Suppression of Betting Houses Act, 1853, which Winston Churchill, the Chancellor, did in 1928, describing greyhound racing as an "animated roulette". Nevertheless, the introduction of tote betting was not accompanied by the suppression of bookmakers. Harringay Park, as it was first called, on Green Lanes, was the second track owned by the Greyhound Racing Association in London, White City being the first. Constructed by Messrs T.G. Simpson of Victoria Street, London, on the "miniature hills" of the Harringay Dump, comprising spoil left over from the construction of the Piccadilly line to Finsbury Park, the course was opened in late 1927. It was equipped with extensive kennelling and training facilities (3). The location was convenient to both trams from Finsbury Park and the LMS station at Harringay on the Kentish Town to Barking line (fig1). Anticipating a more mobile clientele, the promoters advertised its convenient parking facilities. Reportedly costing some £35,000 to construct, the stadium could contain about 50,000 spectators. Familiarity with greyhound racing was not great, and the promoters went to considerable lengths to explain the difference between the new greyhound racing, utilising the mechanical hare, and the traditional sport of coursing thought to be cruel. They also sought to promote the social cachet of racing, claiming that "amongst the number of racing enthusiasts are many titled people. The latest recruit is ex-Queen Sophie of Greece, widow of the late King Constantine." Nevertheless the early facilities appear to have been primitive. The intention was to have evening race meetings during the summer months under electric lighting, during which seven or eight races would be held, with between five and eight dogs in each race. Tote machinery was not introduced for some three years after the start of racing at Harringay, and the course was equipped with its Julius apparatus in 1930. The equipment is almost certainly of Australian origin. Julius's firm, Automatic Totalisators, exporting many machines. The tote machine consisted of five types of interlinked and patented machines, all represented at Harringay, four of which were operational at its closure. They were the ticket issuing machinery, the commutators, the accumulator tables and the display drums. The odds calculating machinery had been disabled, and the type of betting odds display apparatus it used is unknown. Three kinds of bet - win, place and forecast - were supported for a race of six dogs. However it is important to bear in mind that the machinery was identical for each type of bet, the differences simply resulting from the wiring and the numbers of machine. One minor difference is that odds were not calculated for the forecast bet. The win bet, the simplest, requires the machinery to accumulate the bets for each dog and an extra machine for the total of all bets - called the "grand total", making seven machines in all. The place machine similarly requires seven machines, a payout being made on either of the first two dogs, the pot being unequally divided between first and second place. A forecast bet requires the better to name the first two dogs no matter which order they come in, and hence requires fifteen machines for each combination and one for the total. Hence for all bets 30 machines are needed. The rapidly increasing numbers of machines required for bigger races led to six being the standard number of dogs allowed. For example, eight dog races (tried at Catford) would need 47 machines. Machines and display drums were designated with engraved and painted plates showing which bet they represented. Thus 4-W meant dog 4 of a win bet and 1-P dog 1 of a place bet, while 3-5 was for a forecast bet with both dog 3 and dog 5 in the first two places. Grand total machines were usually designated G.T. The first machine, and the only one that potential betters would have any familiarity with, was the ticket issuing and printing machine. At closure there were some 50 operational ticket desks situated at the back of the grandstand, behind wire grills. Each had one operator. At its peak there were about 150 spread round the ground, although the capacity of the commutator machinery suggests that 240 booths were possible. This was not the limit of Julius's ambition. In 1927 he applied to patent an invention for improvements anticipating the use of some 400 to 500 machines (4). |

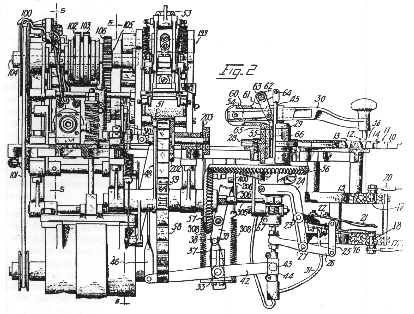

| Fig 2. Diagram of a ticket machine from the patent application |

|

Each machine could issue a ticket for any type of bet, but at only one

price. Particular bets were selected by moving a tram type controller

handle over an arc and selecting one of the pits corresponding to a bet

and depressing the handle (fig2). The movement of the handle caused one

of a series of printing plates located on the circumference of a wheel

beneath the top surface of the machine to come into position ready for

printing. Depressing the handle closed the circuit with the tote

machinery. Printing was inhibited and the ticket not delivered until the

tote machinery later in the chain was ready to receive the bet, in turn

controlled by the commutators in the tote machinery room, a feature

claimed as part of the invention (5). This would normally happen in less

than a second. The completion of the circuit permitted the ticket machine

to issue and eject the ticket, and simultaneously caused a relay to

operate on the accumulator tables. The machine delivered a paper ticket

denoting the value of the bet, the dog and type of bet and the race number.

Hence, a ticket was not printed until the bet had been registered and

properly processed.

The need to control betting so carefully results in part from the very uneven nature of tote betting. Because betters receive starting price odds and these will be more clearly known the later the bet is made, the wise better will place his bet as late as possible, and hence the rate of betting grows towards the time of the start of the race. The machine room was located at the east end of the track behind the main display board, at first floor level (plate 1). On the ground floor was a room containing a mercury arc rectifier, required to provide DC power for the machinery. There was also a workshop with extensive stores of spare parts for the machinery. The machine room consisted of several interlinked units. The main one, about 60ft long and 20ft wide extended to roof height. On the east side were banks of relays, switches and commutators, on a panel about 7ft high and 30ft long. There were also two operator's panels which controlled the machinery. Facing this, against the wooden west wall which constituted the display board, were the display drums. In the middle were three grand total accumulator "tables" for each bet. Each table was about 3ft by 4ft on a strong metal stand. At the south end the disconnected odds calculating machinery was located. These machines were about 12ft long and of similar depth and height. A room to the east, about 40 ft by 40 ft, contained the "individual dog machines" - accumulators for each bet combination. These machines were identical in concept to the grand total accumulators but were arranged in five or six rows separated by walkways, the break between individual dog machines being difficult to determine. The machine room was open, a light metal structure, and the floor was composed of wood blocks. Wires from each group of ticket machines were gathered together, led down the stands, routed round the outside of the track itself and then into the machine room, emerging at the back of the commutator board - a mass of wiring. Each ticket machine was connected to the machine room by one wire for each bet and a return. For a selected bet a wire was connected to the appropriate grand total and individual dog machines returning via the commutator. In consequence, a bet was not registered until the commutator swept the particular stud, going onto the next stud in sequence and discharging its bet, if any, on the appropriate grand total and individual dog machines. Each commutator (Plate 2 Fig. 3) serviced up to eight ticket machines, the rotating commutator polling (although this term is not used in the patents) each contact stud in turn. Julius's commutator permitted an economy on relays and circuitry required to drive the accumulator table without significantly affecting the efficiency of the ticketing process, and he claimed this as a particular advantage in his patent. The commutators were arranged in banks, and swept at the same rate by the commutator arms.

|

| The accumulator tables (Plate 3, Fig 4) on which bets were delivered from the ticketing machines were the computational heart of the totalisator. Bets at different values arrived randomly, and the irregular flows were smoothed and summed to produce a steady output to drive the display drums. The accumulator table consisted of a number of hollow spindles or barrels, typically five in the case of the grand total machines. A barrel represented bets of a particular value, but different barrels could be of different values. For example, the unit bet on one barrel could be £2, while several others processed the minimum bet of 20p. Each spindle contained a long spring which was wound up by a betting impulse. These impulses were delivered by a belt driven epicyclic train which permitted the output of several commutator to be recorded - representing many machines. Julius gives an example where a single table of five spindles, with six escapement wheels in the epicyclic train, and seven ticket machines connected to each commutator, processed the output of 210 ticket machines (4) (Plate 4, Fig 5). These epicyclic trains were composed of cogs and ratchets whose rotation was prevented until allowed to move on one position by the relay. The rotation was then transmitted through to the spring. Ratchets could have different numbers of teeth so that different value bets could be processed on the same barrel, the rotation being greater in the case of higher value bets. Allowing higher valued bets to work the higher valued barrels directly reduced wear and tear on the machinery. These epicyclic trains were normally covered with angled aluminium dust excluders. |

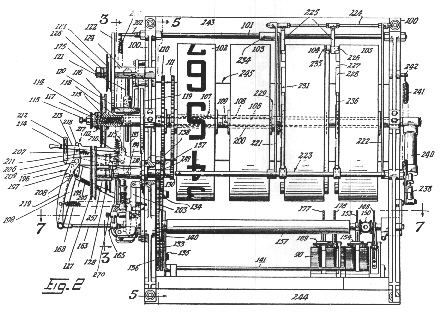

| Fig 6. Diagram of the display drum from the patent application |

Go back to the index Go back to the index

Go to the bottom of the page Go to the bottom of the page

|

|

As the bets were accumulated, they were unloaded at a constant rate

(and the spring unwound) by a permissive clutch at the other end of

the spindle. The output of this could be either routed to the display drums

(where it was loaded onto another epicyclic train) or the output could

be used on the epicyclic train of a higher valued barrel. The speed of

unloading could be changed simply by moving a handle on the table, and this

was necessary when bets were delivered at too great a rate to the table

to be unloaded, which caused a trip to operate and a bell to ring, and

prevented the issue of tickets. Finally the bets were registered on the

display drums (Plate 5, Fig6). In his 1930s patents Julius was to replace

the drums by larger numbers of endless belts, but this improvement was

never used at Harringay. The drums consisted of large rings parallel

to the central spindle of the apparatus, carrying the numbers on the

circumference. They would rotate with great rapidity as betting increased,

so much so that the operation of the units wheel with the constant forces

of stopping and starting Julius's "inertia and vis-inertia" resulted in

a modification in which the units wheel remained at zero until betting

had finished.

The operation of the rapidly rotating drum wheels vexed Julius considerably, and he commented: At the rate at which betting proceeds on a metropolitan race course on a busy day the rate of the rotation of the hundreds drum is so rapid that great difficulty is experienced in reading with any approximation of correctness.Hence, he concluded: it was found impracticable to apply the registration mechanically to all drums and indicators and rely on those drums and indicators to operate on each other in decimal progression in the manner of a revolution counter(4).At Harringay only the units counter seems to have been disabled in this way, and in the abandoned place drums (see below) the units were not disabled. To work this complex machine the totalisator required, in addition to ticket sellers, some 16 people. The machine itself was maintained and operated by the chief engineer, Mr Bowler, who had been employed at Harringay 23 years, and his assistant. During the evening they where joined by a team of six whose sole function was to reset the display drums and counters to zero in preparation for the next race. One or two other staff helped in reading the veeders. In the office beyond the machine room, Mr Carrouths the racing manager, was assisted by an accountant who oversaw the duplicated calculation of the payout by his two assistants. Two telephonists where also based here, as well as the quinella, duella machinery operator. Most of the staff were employed for the short period of an afternoon's or an evenings racing. The senior staff where permanent, working on both racing and non-racing days. Mr Bowler would arrive around 10.30 am and his day was taken up with maintenance tasks, unless there were afternoon or evening racing. If the latter, he would not leave until well after the last race. Nor was the job suitable for anyone who wanted bank holidays. Nevertheless, the GRA was considered an excellent employer. The cycle of Tote operation is the same for each race. The best point to begin with is the announcement of the forecast or payout from the previous race. The engineer checks that the veeder and the display drums are correctly set to zero - the latter as a series of 5s upside down will ensure that they are set to zero. The reason for this concern for the drums, whose numbers where rarely used by the public, and not at all by the Tote staff, is that they remain the "legal display". Satisfied, and ensuring that the race number, displayed on an illuminated screen on his race panel, which will be printed on the tickets sold, has been advanced on the control board, he switches the race locks "off", permitting the ticket machines to work. Gradually, superimposed on the background noise of drive belts and pulleys the characteristic sound of bets being processed through the accumulators is heard. This noise grows as the drums begin to turn. The irregular and staccato rhythm grows towards the start of race. Mr Bowler tends the machine, observing a veeder here, a drum display there. Occasionally, an alarm rings on one of the accumulator tables ,causing a light globe to illuminate. Too many bets have been received on one of the spindles of the accumulator table, and a switch is triggered. It is quickly corrected by adjusting the processing speed of the table, which is not high with the decline in business at Harringay, and resetting a trip. Eventually, when the time of the race is reached a bell is rung, operated by the opening of the traps on the track. Mr Bowler turns the race locks "on" at the control board, freezing any bets that have not been completed, and there is the characteristic sound of the units drums, which have hitherto been disabled turning incrementally into position. From the point of view of the tote team this has been the quiet part of the cycle. The first activity is recording the veeder counters. These are positioned at many points throughout the machine - beside the display drums, on the odds calculating machinery and on the individual dog machines. These are recorded and taken to the tote office, where they are handed to the calculating assistants who will prepare the forecast. Curiously, the display of the same numbers on a special unit in the office, part of the output of the electronically calculated odds display, is not used at all. Meanwhile, since the end of betting the telephonists have been receiving calls of bets in error, as the Julius machine cannot correct bets wrongly made. These are summarised and formally written on a slate on the wall, and are deducted from the pool for the race. The calculating assistants go to work. The results are written on standardised forms and the erroneous bets deducted. The operator's profit and tax are calculated and also deducted. From the remaining amount the "dividend" or forecast of the winners is calculated, and having satisfied himself, the accountant reads the dividends from the small soundproof Tannoy booth, which broadcasts round the whole stadium, informing the payout booths and betters who can cash in their winning tickets. From the end of the race less than ten minutes has elapsed. Meanwhile in the machine room, when the tote office is satisfied with the figures they have received, the machinery is reset. Firstly, the units drums are reset automatically from the control pane. Then, the resetting team turns the drums back to zero, an operation requiring a surprising amount of manual dexterity, and resets the veeders. Veeders on the individual dog machines and the grand total tables are zeroed. The totalisator is ready for the next race. With the decline and partial modernisation of Harringay, a considerable quantity of machinery was not in use. Large numbers of ticket issuing machines had been disconnected. Consequently, the commutators they were attached to were not operational, though they remained functionally connected. A complete set of disconnected display drums were still in their original positions. They had a smaller number of counter wheels than the working drums and it is tempting to conclude that they were superseded as business grew. The most important disconnected machine was the odds calculator, used to compute the instantaneous odds for each dog in the win bets. In his patent for this machine (6)Julius states its utility: In the excitement and hurry which precedes a race it is of great importance to offer to the investor an instant statement of the odds available to him.While this is of importance to the investor, the odds calculation was not a legal requirement, that being the display betting totals on the display drums. The odds calculator consisted of six identical machines made up of two long leading screws at right angles. One of these screws was turned from the grand total machines, the other from one of the individual dog machines by a driving apparatus in front of each machine. As the screw was turned carriages on the screws moved proportionately. The ratio of the distances that each carriage travelled gives the odds. As Julius saw it: The problem to which the invention is addressed is to provide a device for indicating the ratio between the "dividend" figure and the "divisor" figure whilst either or both of those figures are progressively changing so as to represent the quotient for the time being as a simple fraction.This was achieved by joining the carriages by a quotient arm whose angle represented the odds. This was all that remained of the odds calculator, and in the patent Julius goes on to describe how the arm position is used to provide an output which can be seen throughout the course. Connected directly to a "Selsyn" electric motor, the output can be transmitted to any number of connected display dials round the course. These could be marked either with odds or payout for a particular bet. None of the display mechanism had survived. The odds calculator had been replaced by a system connected to the tables themselves, in which rotation of a drive shaft was counted by reed switches which were processed to provide an electronic display showing the odds of each dog in turn. These counters were contained in the boxes which could be seen prominently fixed above the tables. The odds calculator permitted a number of sophistications. For example, the effect of a constant proportionate take for operator's overheads or tax could be calculated simply by turning the grand total wheel slower than the individual dog wheels. Place calculations (where first second and third places get different proportions of the winning pot) can similarly be calculated. Where the machinery was operational it was in excellent working order. It needed to be. Any errors in the computation of payout had to be borne by the company. It was thought that the error rate was "one in a million", but no evidence was given for this figure. After the course closed the machinery was quickly removed for scrap with the exception of a representative sample which was taken by the Science Museum (7) and is currently in store pending re-erection. That Harringay survived so long is an accident of the GRA's long standing intention to redevelop the site. It simply became too uneconomic to replace the machinery for the short life the replacement would have had. Julius's patents uncannily foresee many of the problems to confront designers in a quite different field - computers (8). It is perhaps surprising that the special problems posed by as simple a concept as tote betting, should require such a wealth of invention to solve. That today the solution is a relatively trivial computer application detracts not at all from Julius's work. References

AcknowledgementsMany GLIAS members were involved in this project and the site work was done between August and October 1987. Special thanks are due to Dr Robert Carr (who also provided the photographs for this article), Mary Mills (for oral history transcripts) and Danny Hayton. A video was made by Andrew Keene. Without the invaluable help and advice of the Greyhound Racing Association Ltd, in particular John Morgan, and Eric Bowler, Chief Engineer, this project would not have been possible; their contribution is gratefully acknowledged. Thanks are also due to Tony Sayle, of the Science Museum, for visits to the surviving machinery at its Wroughton site.Glossary

|

|

Whilst we are on the subject of a Julius tote in England, here are some other Julius Tote installations in England. Some other installations in England

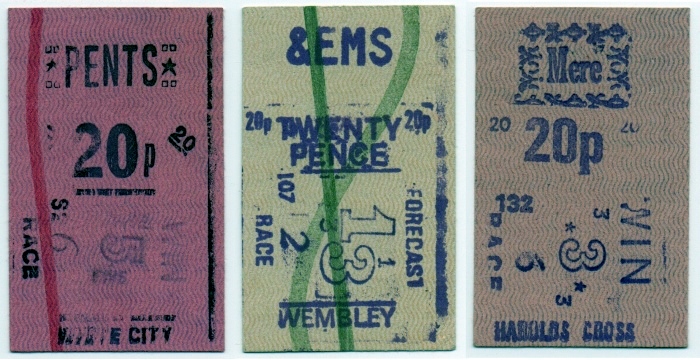

Having provided a list of some other installations in England, following are some tickets two of which come from tracks mentioned above, courtesy of Chris Robertson an ex High Value Punter in Melbourne who is an expert on Automatic Totalisators Limited's products. The left hand one is from White City London and the middle one Empire Stadium Wembley London. The third is from Harolds Cross Ireland. The Julius Totalisator at White City is the largest Julius Totalisator that I know of which had 320 terminals. There are several pages relating to the White City Julius Tote in the Photo Gallery continued chapter of this website accessible through the Finally section of the index by selecting Go to the index in the navigation bar at the bottom of this page. In the Photo Gallery continued chapter the first group of photos are titled Hialeah racetrack in Miami 1932 and that is followed by the White City group in question.

Whilst still on this subject, I received an email from John Relle in October 2013, who indicated his father Vernon was the Chief Engineer of Totalisators Limited. This company was Automatic Totalisators Limited's associate company in the United Kingdom. In August 2014 John provided the following information about his father and Totalisators Limited. John mentions the GRA. Harringay Stadium, the subject of he above article, was the third greyhound racing stadium to open in Britain. It was owned by the GRA, the Greyhound Racing Association Ltd. John Relle's information regarding Totalisators Ltd.Totalisators Ltd. had offices in Park Street, Mayfair number 91 I think. Then in the late 60's moved to Prudential House in Croydon. My Father was Chief Engineer and Dick Chiltern was Managing Director (before him it was a man called Whatley, I cannot remember his first name). My Father spent some time in Australia I think in the 1950's He installed totes in Longchamp Paris France, Cleveland Ohio USA, Rio de Janerio Brazil, Ashanti Gold Coast (now Ghana), Solvalla Stockholm Sweden and Cork Ireland. Also some in England. He also designed and installed one of the indicator boards at the old Wembley Stadium. I know they did a lot of work for the GRA in the UK I think the company was bought by Ladbrooks in the years before my father retired. If anything more comes to mind I will let you know. |

|

If you have read this far, you will probably be interested in having a look at some video clips from Andrew Keene's excellent video of The Harringay Greyhound Stadium's Julius totalisator

I have been told that Harringay was the last Julius totalisator to cease operation however an email I received on 18 Aug 2000 by Iain Harrison suggests that a Julius tote was still operating after Harringay closed. I have included Iain's email here.

Iain's emailI was delighted to stumble across your series of pages on the history and development of electro-mechanical totalisator equipment whilst surfing around various historical engineering sites. I really enjoyed your pages and would like to say thanks for reminding me how fascinated I used to be watching this type of equipment work during visits to local dog tracks throughout my childhood and teen years. I have just read the article you reproduced from GLIAS regarding the installation at Harringay Greyhound Stadium and am curious as to your statement before this article that this particular equipment was the last to cease operation in 1987. I have spent a good deal of time at local greyhound tracks ( in the northwest of England ) from the early 1970's to the present day and I am certain that Julius equipment, as described in the GLIAS article, was in use at the Preston Greyhound Stadium ( Acregate lane, Preston, Lancashire, England ) until this closed around 1988 / 1989. This track held meetings on 3 evenings per week and had, I guess, about 40 to 50 ticket selling / issuing machines, total and odds display boards etc. Furthermore when the track at Preston closed, some of this equipment was transferred to another local track at Blackpool, England. This was a smaller track with maybe 15 or 20 ticket machines, but still with indicator boards showing totals for win, place and forecast bets / payouts etc. This track in Blackpool closed around 1994 / 1995 and still used this equipment until then, as far as I can remember. Would this have been another style of electro-mechanical tote equipment ? I fondly remember visiting the 'control' room at the Preston track and remember the equipment being identical to that described in the GLIAS article. I am very sceptical that the last use of this equipment was at Harringay - do you have any further information ? Once again, thanks for a most enjoyable web site ! |

|

Following is an email I received on 3 September 2000 from Ernest Bailey relating his memories of Harringay.

Ernest's emailBrowsing the internet recently I entered Harringay Stadium on the search key and was amazed that the Julius Totalisator was featured. I was employed on the Tote from 1941-43 and then called up for war service. I returned to Harringay in 1947 until 1966. In 1956 I was made relief engineer to take over from the White City, Bellevue, Powderhall and Hall Green engineers when they were on their annual holidays. It was mooted that I would take over from Bill Bailey (no relation) the resident engineer when he retired in 1968. The long-standing stalwarts, Len Monk, Jack Haddock, Arthur Lawrence had all retired or were soon to retire. With nobody experienced to help me in my proposed elevation, I decided to leave in 1966 and move to Grimsby for other employment. I did not know that Harringay closed down in 1987. I knew Eric Bowler well. He was a motor mechanic who was introduced as a part-time mechanic for the evening meeting by Bill Bailey. Soon after, he was appointed second in command engineer to White City in the 1950s. When Bill left it appears he took over at Harringay from 1968 to 1987. You do not mention Bill who was the resident chief engineer from 1930 to 1968. He was, in my opinion, the best engineer of the Julius Tote I ever came across. His son Henry worked at White City and he too was very brainy electronically. I have many fond memories of my time at the G.R.A. Are any of the G.R.A. engineers still with us? If you have any titbits that you think may be of interest to me I would be grateful for the information. If you would like further news of specific memories of mine regarding the Harringay Tote I would be pleased to let you know. Regards Ernie Bailey And some extracts from an email sent on 20 October 2000. This is the only feedback I have had regarding what problems were encountered working on these systems. I found the Cheetahs particularly interesting.

Extracts from Ernest's second emailThere is another chap who may be in your archives. His name is Thornton. An Australian. As a consultant for the workings of the Julius tote, he was brought in to advise on the technical troubles we were having at Harringay. At a guess, I think this was about 1947. Apart from that there was very little trouble on the Julius tote. Just odd things like an escapement wheel tooth breaking or an 8 ohms going open circuit. The public display drum belts often broke at the staple. I often wondered why we never fitted endless belts to the pulleys. On the TIMs side they were more prone to break down. The main problem was the ticket paper concertinaing. 3 reasons for this. 1: was a blunt guillotine. 2: was the rubber roller wearing on one side and so not pulling the ticket paper through properly. 3: and this was the greatest fault, namely the aluminium paper chute, too much width on the guide channels was allowing the ticket paper to wander in the M/C. When we riveted a couple of M/S channels closer to the width of the ticket paper 90% of our concertina troubles were eliminated. Looking back now, the Julius tote was noisy, mechanically cumbersome and old fashioned compared to the present electronic marvels we have now. But boy oh boy, with all its faults, it was extremely accurate. All those millions of bets it assimilated and registered, it was truly amazing. P.S. Did you know Harringay tried to race cheetahs around the track just before 1930? Some would run, some wouldn't. It was a complete disaster and a definite no no. How they envisaged making the public safe from these animals is not known. |

|

Following is an email I received on 27 October 2011 from Neil C, relating his memories of Harringay. I must mention that Neil is correct, Forecast bets do require the selections to be in the correct order. I have not changed the above article as I did not write it.

Neil's email

Hi

I started as a ticket seller on a Forecast window. I can still now feel the solidity of the operating handle as you swung it round to record bets and print the tickets, everything was brass & shiny. I have to correct one part of your article though. At Harringay forecast bets were specific as to the order the dogs finished. Hence a bet on 1-2 would only pay out if dog 1 came first and No.2 second. A 3 dog combination, probably the most popular forecast bet, was therefore a total of six bets/tickets. You quickly learned that a "1-2-3 dog combination" meant punching 1-2, 1-3, 2-1, 2-3, 3-1, 3-2, £1.20 at the 20p basic stake. "1 & 2 about" meant punching 1-2, 2-1 and cost 40p. To try and prevent fraud each race had its own colour of ticket, the spools of blank paper having to be changed between races and a test ticket printed to prove what colour paper that machine had been loaded with. The actual colours used were chosen at random from a stock and were always different meeting to meeting. I presume that there must have been 30 machines recording the Forecast bets, not the 15 mentioned in your article as I was able to punch out a total of 30 individual bet combinations. Hitting the correct holes at speed was a skill soon learned or you had a hoard of angry punters baying at your window. I later moved into the Tote control room from where the betting was monitored and dividends (payout) calculated. The room lay next to the totalisator machinery on the first floor behind the indicator board. My first job was calculating the Forecast dividend and eventually I became assistant to the control room manager, overseeing the correct calculation of dividends. All calculations were carried out manually on early electric calculating machines. All calculations were independently double checked, three staff calculating Win, Place and Forecast. Dead heats were a nightmare and practiced occasionally for the odd occasion one occurred. We also practiced calculation the dividends manually, just in case the electric calculators failed. One oddity of the equipment I recall was the need to read the final digit of the total of win and place bets recorded from the totalisator machinery itself. By the time I worked there the control room had electronic indicator boards showing the number of bets placed relayed from the totalisator machinery. For some reason never explained we had to check that the last "unit" number displayed was correct. I assume that the link from the equipment was not quite accurate enough. Hence a member of the control room staff had to take down the numbers as read from the machinery by a member of the engineering staff who looked after the equipment. Sometimes it was a judgement call exactly which number was displayed on the brass counter wheels as the numbers did not always line up exactly in the viewing window. As most races took less than a minute to complete there was always a rush after waiting for the machinery to record the last bet then read and record the numbers and get these to the calculating staff so that dividends could be calculated the moment the judges announced the result. We had to get the winnings paid out quickly to maximise betting time on the next race. The machinery was magnificent. The noise and smell were unique and all the brass was always kept shining by the engineers. Their pride in keeping the equipment up to scratch was wonderful. I had heard that the totalisator equipment had been acquired by the Science Museum of London after Harringay closed down. A search of their website unfortunately reveals nothing. I do like to think that the equipment was re-housed somewhere and not just scrapped. It deserved better than being melted down. Warmest regards

If you go to the bottom of this page and select the Go To the Index Menu Bar Option, then select the 3 More ATL Systems in Asia/Links to other pages link then scroll down to the A Visit to London heading you will read about the Harringay system in the London Science Museum's Backup Stores at Wroughton.

On 28 October Neil wrote again. Following is an extract from that email. I have included it here as it contains a method of mentally calculating 16.5% of the Net Pool required to extract the commission. I find this sort of thing fascinating and a good example of lateral thinking. I think it would have taken me a long time to dream this method up and it is certainly eloquent.

Extracts from Neil's second emailGlad my mail was of interest. Working on the Tote at Harringay was a happy time for me. It was where I was taught practical mathematics. Like being able to add up a column of figures quickly and calculating 16.5% without a calculator. That was the percentage deducted from the prize pot for tax and running costs. ... 16.5% is simple, take 10%, halve it, take 10% of the first figure and 10% of the second, add the four together. It involves moving a decimal point and one simple division by 2. Who needs a calculator? ... Regards and thanks for your website that has evoked some happy memories. |

|

Following is an email I received on 2nd April 2013 from Sue Vost relating memories of Harringay

Sue's email

Hi

Harringay stadium was a big part of my childhood as both my uncles raced greyhounds and my dad (John Adams) was chief electrician there for many years. Not sure who was chief engineer at the tote during my time there, but I do remember an engineer named Mick Berryman. If you could connect me to Neil I would be grateful as we were happy workmates for several years! Regards,

|

|

Following is an email I received on 13th October 2016 from Bob Rowe relating to the Julius Totalisators, after I contacted him through the Greyhound Racing Association and Owlerton Stadium in Sheffield, whilst visiting in October 2016.

Bob Rowe's emailHello Brian,

I read with interest your knowledge about the history of the Julius totalisator operating system at Harringay. Working for GRA Ltd., in London I was in charge of the racing department at White City from 1973 until the closure of the stadium on 23rd September 1984. I had virtually no involvement with the tote department, the manager of that was Jim Carruth, who had previously held the same role at Powderhall, Edinburgh. Sorry, but I can't remember the system in use at White City - it was well over thirty years ago, however the name Ericsson rings a faint distant bell! During my White City years I would occasionally visit Harringay on racing business. It was a good race-track and was very popular -as all the fifteen greyhound tracks in London were - in it's heyday. My first visit there was in 1962, I think, for a Variety Club meeting in the presence of H.R.H. The Duke of Edinburgh.The crowd was massive, at least 12,000 I would reckon maybe more. It wasn't a little stadium as was suggested elsewhere. Indeed I have a feeling that apart from Wembley it stood on the largest acreage of any track in London. Hence it's great land value. Two colleagues whom I remember very well and who were mentioned in the article were Henry Bailey, the son of Bill Bailey and who succeeded his father as Chief Engineer of GRA Ltd., and also Eric Bowler, who progressed from tote engineer at White City to tote manager at Harringay. The two tracks were about ten miles apart. I am unsure whether Henry is still alive. He retired to Norfolk about 1990 from his last track at Slough. I have not been in contact with him since then. He would be a massive source of information. Age-wise I guess by now he would be about ninety. I hope this is of some little help. Regards,

When I replied to Bob's email, I mentioned that Owlerton Stadium was close to the grounds of Sheffield Wednesday Football Club. Bob informed me that their grounds were half a mile away. My interest in Sheffield Wednesday Football Club was a result of my cousin Michael having previously informed me that as a family member it would behove me to be a Sheffield Wednesday supporter! I also made the observation that there is nothing left of the White City Stadium, as I discovered a couple of trips to London ago, to which he wrote the following: As far as White City is concerned you are correct nothing that I know of remains, except that Hammersmith Council retained the name of the road and which still exists - White City Road - but the road signs are not the originals! I went to White City again during this 2016 visit to London. Even the BBC premises that had occupied the land on which White City Stadium stood was in the process of being replaced by a new housing development. The name of the new development is TELEVISIONCENTRE as this area was called the home of British television. |

| Acknowledgements |

|

| Previous page | Go to the index | Top of the page | Next page |