This technology history page contains an image of a photograph which is one of several belonging to the photo gallery pages which are part of several pages relating to the invention of the world's first automatic totalizator in 1913 and Automatic Totalisators Limited (ATL), the Australian company founded in 1917 to develop, manufacture and export these systems.

Copyright © 2001 Email - totehis@hotmail.com

The First Computer Based Tote Systems- Autotote ATL

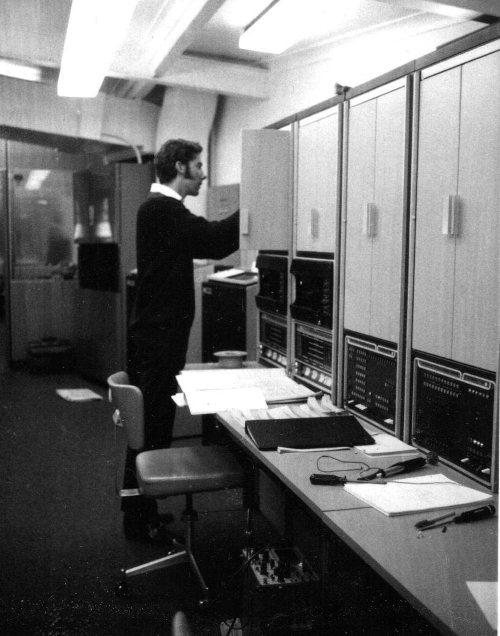

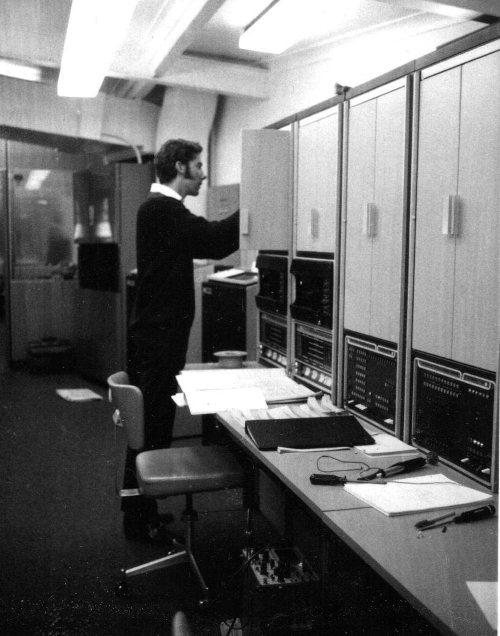

The image below shows an Early Computerised Totalisator System. Bob Plemel, who was a long serving Engineering Manager of Automatic Totalisators Limited and later worked for the Digital Equipment Corporation the company that manufactured the PDP8 minicomputers shown in this page, wrote the following about this system: I believe it may be one of the first systems built by Autotote. It is a photo of the original PDP-8 not the PDP-8I that was used for Happy Valley.

Autotote that Bob mentions, was Automatic Totalisators Limited's American subsidiary company, which started out with the name ATUSA (Automatic Totalisators USA). The Georgetown USA PDP8 system developed by the company was the world's first totalizator based on minicomputers and followed the Honeywell 200 based system developed by the company for the NYRA (New York Racing Association), which was the world's first computer based totalisator system. The NYRA was a big project involving 3 racecourses Aqueduct, Belmont Park and Saratoga. You can read about this in the Automatic Totalisators in America chapter of this website.

More after the image...

Click on the image to go back to the Photo Gallery

If you arrived from navigating the website, use the navigation bar at the bottom of this page.

When Bob Plemel informed me that the PDP8s in the tote system shown above pre-dated the PDP8/I and could have been built by Automatic Totalisators Limited's American subsidiary company in America, I started to wonder if it could be the Georgetown system which was the first of the PDP8 totalisator systems. I compared it to an image of what was thought to be the Georgetown system shown below and they certainly look the same. I suspect that the image above, as it is the front page of what is obviously a marketing/sales document, would have been based on a milestone system. As the PDP8 system at Georgetown was the world's first minicomputer based totalisator I think it is highly probable the image above is of the same system.

The following description is written with reference to the image above, only because it shows greater detail, as it also applies to the image below. On the right hand side of the blue workbench, which spans all of the racks, bar the space occupied by the two control consoles, there are three PDP8 Minicomputer control consoles and two Paper Tape Punch/Readers. Their front panels are immediately above the blue bench. Of these front panels in the right hand five racks, the PDP8 consoles are in the racks that have the double brown doors above them. Near the middle of the blue workbench, are two TCCs (Tote Control Consoles) with their specialised keyboards in the bench with Board Control Units (BCUs) above them. Above the left hand end of the workbench are three Scanners, which interface the TIMs (Ticket Issuing Machines) to the computer systems. The centre opening doors in every rack hide all the electronics backplanes and wiring.

Probably the Georgetown totalisator

Probably the Georgetown totalisator

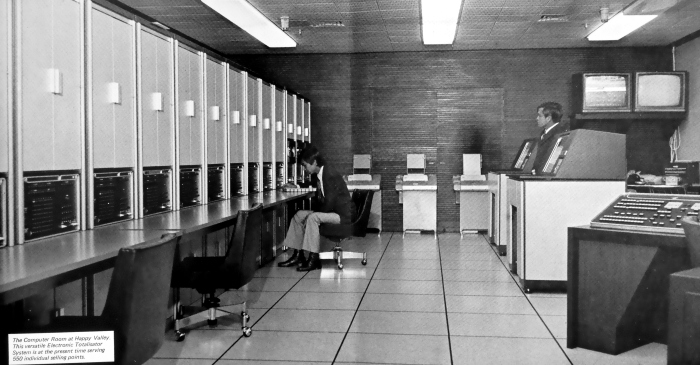

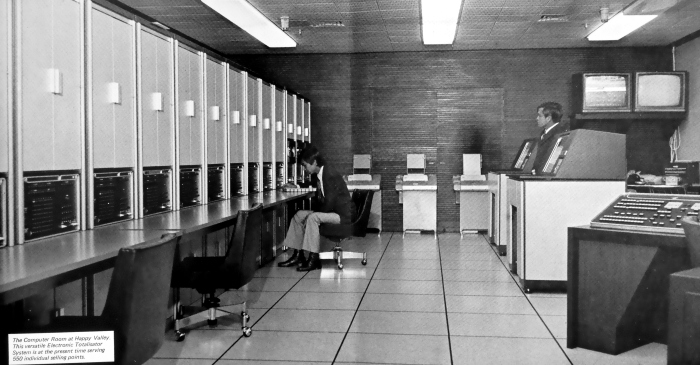

The PDP8/I based totalisator, developed for the Royal Hong Kong Jockey Club's Happy Valley track, which Bob Plemel mentions at the top of this page, is shown in the image below. Also shown in the image below, is Bob who is standing. The letter "I" appended to the PDP8 name signifies that this model of PDP8 has a hardware implementation utilising integrated circuits. The Happy Valley system below, as is the Georgetown system above, a Triplex system which was based on 3 PDP8/Is. These consisted of three CPUs each capable of performing the functions of Master, a hot-standby Slave or a Catchup mode machine.

Max Burnet, was the CEO of DEC Australia (DEC - Digital Equipment Corporation), the company that manufactured the minicomputer systems Automatic Totalisators Limited (ATL) based almost all their computer era totalisators on. DEC was the number two computer company in the world next to IBM around the end of the 20th century. DEC and ATL had a long relationship spanning many generations of computer starting with the PDP8s followed by the PDP11s and later VAXs ending with the Alphas. ATL was a class of customer of DEC termed an OEM (Original Equipment Manufacturer.) Max gave me a copy of his DEC Australia history DVD. In this history is a list of customers and machines titled At this time the earliest installed machines were:- which records Automatic Totalisators having two PDP8s with serial numbers 564 and 740. These pre-date the PDP8/Is and were termed Straight 8s. From these serial numbers Max estimates these would have been 1964 models well pre-dating the Happy Valley project. Max speculates that these machines were probably in the ATL Research department or the ATL Development Lab. I have met multiple ex DEC employees, including Max, who believe that ATL was significant in getting DEC Australia established.

It is interesting to note that in the DEC History DVD list, PDP8 serial number 564 is recorded as ending up in the NSW SU Museum. Regarding the ex ATL PDP8 being donated to the SU Museum, Max wrote the following: It sounds like Bill Johnson gave one of these to the university when it reached end of life. William Johnson wrote the following about this: I bought the 4 PDP-8s from Harold Park and Wentworth Park. Eventually sold them to deserving technical persons. The first PDP-8, all transistor, from research I gave or sold to my nephew Max and it ended up outside the maths department at the University of New South Wales.

The Happy Valley system being developed

To the left of centre in the above image, towards the bottom in the two racks that can be seen full length, there are groups of five cable looms dangling down and joining into a single horizontal loom. This is the wiring that connects the TIMs (Ticket Issuing Machines) to the front end system of the totalisator. The front end system consists of devices called Scanners which Automatic Totalisators Limited designed and manufactured to interface with the TIMs and indicators which the company also designed and manufactured.

Note that in the image below, when the system enters its operational phase, double sided doors below the workbench are fitted to protect the cabling and improve aesthetics. Similarly when comparing the image above with the one below, double doors are fitted on the upper section of each rack when all the work on the backplane wiring is complete and the development phase ends. The person seated in the image above seems to be working on one of the backplanes. Additionally, during the development phase, in the image above, the workbench is a hindrance in gaining access to the equipment racks so it is only installed when the computer system enters the operational stage as in the image below.

There seems to be an almost circular, tyre sized feather duster lying on the floor under the cabling mentioned above, shown in the image above.

On 23/03/2018 Dick Sterndale-Smith ex Chief Programmer at ATL, wrote to Bob Plemel about my previous sentence:

I don't believe that this throw away sentence is correct... All I can remember was that the RHKJC system was staged out on the factory floor, and back in those days it could get pretty hot. Was that thing some sort of fan?

On 29/03/2018 Bob Plemel replied:

I had another look at the original photo but have no idea of what the device is... Bertha thinks the photos were done by a professional photographer team that were at ATL taking photos and videos of the building of the RHKJC tote system. She remembers the wiring girls being photographed. Maybe the device is part of the photographers kit.

Note: RHKJC is an acronym for Royal Hong Kong Jockey Club.

The Hong Kong PDP8 Totalisator System at Happy Valley

Bob Plemel wrote the following about the two images above: The Happy Valley system was built in late 1968 and was shipped to Hong Kong in early 1969. I went to Hong Kong in March 1969 as part of the installation team and did not leave until November. It went live about August 1969.

The Tote Control Console or TCC visible in the image below, which belonged to the Happy Valley totalisator in Hong Kong, can be seen in the image above on the far right hand side on a separate table. Bob Plemel, shown on the left hand side in the image below, made the following comment about this TCC in the image above: I remember that in Hong Kong they were mounted in a custom made teak wood desk - very posh for a tote.

Bob Plemel on the left and the PDP8 TCC

Bob Plemel on the left and the PDP8 TCC

Bob Plemel also mentioned that the TCC in the above image, which was photographed in the Meadowbank factory, was a spare. The Royal Hong Kong Jockey Club wanted a spare TCC. Spares are always a good idea to eliminate single points of failure.

A video camera can be seen on a tripod on the left hand side of the above image. Bertha Schoder an ex Automatic Totalisators Limited wiring expert recalls that a production company were making a film of the Happy Valley totalisator system in the Meadowbank factory. Bob and I were having trouble identifying the man on the right hand side of the above image however Bertha suggested he belonged to the film production company.

Neville Mitchell, an ex ATL Manager Engineer and draftsman made the following comment about the TCC in the above image:

I do remember being involved with the design of the RHJC Tote Control Console under the guidance of Peter Rolls. All of the push button keys were made in Germany and assembled into rows by RS Rubin & Co in Whiting Street Artarmon. The keys were mechanically interlocked some with only one key in the row being enabled at the one time others with individual latching but with a cancel key on one end of the row. The mechanical designer was design draftsman Bill Bryant he was also responsible for the six foot racks and the various ATL control panels, eg scanners, Indicator control etc.

It's a great photo of Bob, I too am puzzled what the other guy's name is, I just know I knew him!

Having mentioned Bertha Schoder in the paragraph above Neville Mitchel's comment above, the following image shows Bertha standing in front of a PDP8 based totalisator system in the Meadowbank factory.

Bertha in front of a PDP8 based totalisator

There are three reasons why I think the image above also shows the Hong Kong Happy Valley totalisator system:

- Judging by Bertha's youthful looks in this image the original photograph was probably taken around the time of the Happy Valley system project.

- Bertha informed me that the man standing in the image immediately above was a member of a photographic company taking photos of the system. I think this man standing could well be the man standing on the right hand side of the image above titled Bob Plemel and the PDP8 TCC, although the latter image shows a more rearward profile making it more difficult to compare the features of the man referred to in the two images. As previously mentioned, the man on the right in the image above titled Bob Plemel and the PDP8 TCC is probably a member of a photographic company making videos and photographs of this system, which adds credibility to the thought that they are the same person. If this is the same person in both images then the image immediately above is almost certainly showing the Hong Kong Happy Valley system.

- Bertha also told me that the seated man in the image above is Ron Hood. That could also be Ron Hood in the image above titled The Happy Valley system being developed, where a man at the left hand edge, is seated in a similar if not the same position on a similarly constructed or same chair with what presumably are the wire wrap routing schedules sitting on a table like object on his right hand side. Again, if this is Ron Hood in both images then the image immediately above is almost certainly showing the Hong Kong Happy Valley system.

Bertha Schoder wrote the following about the image immediately above, after reading the text associated with the initial inclusion of that image in this page:

I think I told you that it took me 16 weeks to wire up the PDP8. It was a lot of wire wrapping and connecting the cabinets together.

Neville Mitchell wrote the following about the image immediately above, after I asked him which project the PDP8 system shown in it belonged:

I'm reasonably sure this is RHKJC first PDP8 I system the wire wrapped units are scanners and Ron Hood with back to the camera is obscuring the ICU unit. I can not identify the other fellow. Ron Hood did all the wire wrap routing schedules for the wiring ladies.

Note: ICU - Indicator Control Unit.

Bertha was in the wiring section and was famous within Automatic Totalisators Limited for not making mistakes when wiring backplanes, like the ones in the upper sections of each of the racks with all the yellow wiring in the image above. Wiring backplanes was very demanding work requiring sustained concentration. If any mistakes were made in this wiring it could be time consuming to find them, which is why Bertha's skills were so highly sought after. Bertha is holding a wire-wrap tool in her right hand in the image above.

Neville Mitchell added the following comments about the image above:

Berta is sure the other person in the scene was the camera operator.

You are correct about faultless wire wrapping by the specialised girls they did the work from routing methods sheets. Then two electrical inspectors Belled Out the wired back plane, one reading the sheet the other using the buzzer to check each circuit. I worked in electrical inspection when this testing was done and there was never a remark made about a incorrect wire placement.

The image below shows a close up view of the PDP8 backplane wiring showing detail of what exists in the upper parts of the two right hand racks in the image titled The Happy Valley system being developed above. The image below also gives a good view of part of the PDP8/I console below the backplane.

PDP8 Backplane Photo by Max Burnet and Peter Watt

PDP8 Backplane Photo by Max Burnet and Peter Watt

As I looked closely at the PDP8 console in the image above, I noticed something interesting about it. On the far left hand side, apart from the other text on the front panel identifying the lights and switches, there is a machine code program titled Rim Loader, consisting of two columns of octal numbers. You don't see that these days, as this program has been stored in ROM for most of my time in the industry and I started in the 1970s. This program relates to the ostensible paradox of how do you load anything into main memory to be executed if there are no instructions in main memory to be executed? This program solved this paradox and was given the generic name Bootstrap Loader which has a PDP8 specific name RIM (Read-In Mode) loader. The Bootstrap Loader gained its name from another ostensible paradox of Why can't you pull yourself up by pulling on your own boot laces? The Bootstrap Loader is a small program which was relatively easy to toggle into main memory via the console switches, which when executed loaded another loader called the Binary Loader. This loader is more extensive than the first and is capable of loading and starting the operating system. The Bootstrap Loader imprinted on the PDP8 console above consists of two columns, the first contains addresses into which the instructions are loaded and the second column contains the instructions to be loaded into those addresses. I can recall a short period at the beginning of my time in the computer industry of having to toggle in the bootstrap loader to start the computer up.

Max Burnet wrote the following about the work Rob Stone is doing at Harold Park shown in the image below, which is performing field changes on a panel like the one shown in the image above, which Max provided with this note: When Rob Stone talks about re-wiring the PDP-8/I, this is the daunting wiring complexity that he faced. The photo shows the PDP8/I backplane. Factory wiring was done in red. Field changes were usually done in yellow.

Rob Stone with Duplex PDP8 system at Harold Park 1970

The Harold Park system which Rob is working on in the image above, was the first computer based totalisator in the Southern Hemisphere. Rob wrote about this job:

I was given responsibility for installing the computer systems at Harold Park and Wentworth Park, supported by Peter Rolls, Ron Hood, Kevin Franks etc. in Installation, George Klemmer and team in Research, Dick Sterndale-Smith and programming team under George, Neville Mitchell Alf Lesins and team in the Drawing Office, and Alan Lakeman Bill Johnson and team on track

In the image below a Tektronix 465 CRO (Cathode Ray Oscilloscope) can be seen sitting on the desk in front of the seated person. Additionally, in the image above another Tektronix 465 CRO can be seen sitting on the ground face up on the near side of the chair below the edge of the bench. The knobs and dials on the shiny front panel can be made out in the gloom. Additionally, near the top left corner of the second image on this page titled Probably the Georgetown totalisator, there are two CROs. The right hand one is standing on a trolley and judging by its size is a valve model. On the left is a more compact transistor CRO, which looks like a Tektronix 465. Neville Mitchell recalled the following about an early one of these Tektronix 465 CROs in the research department of ATL, along with other equipment in an email to the ex ATL fraternity after seeing these images.

I do, as most of you will remember, the TEKTRONIX 465 oscilloscope. In the Research department there was also an ancient Marconi Scope single trace and not very fast, The Tektronix 465 scope must have cost a lot as it always appeared on the Asset Register and the depreciation cost on the taxation returns.

Recently in a Cash Converters Shop I watched a man sell a 465 in what looked like new condition for a princely $10! It still had all of the leads in a soft blue PVC pouch.

Another research instrument I remember was the AVO 8 Multimeter, I recently donated one to Bob Moran's Discovery Shed.

In my drawing office we were proud users of a General Electric "Genius" Imperial to Metric conversion calculator, used by the draftsmen to assist with changing to metrics. It had a capital value of $280 at that time.

Max Burnet wrote the following: The first PDP-8 that DEC made around 1965 was made of transistors and diodes.(These were the R for red modules). Over time it has become called the "straight" 8, or the "classic" 8. I remember this hardware implementation well, based on the DTL logic family (DTL-Diode Transistor Logic). I also remember the RTL logic family (RTL-Resistor Transistor Logic). Most of my decades repairing computer systems, were spent working with the TTL logic family (Transistor Transistor Logic). In later years this became increasingly MOS and CMOS logic families (MOS - Metal Oxide Semiconductor and CMOS - Complementary Metal Oxide Semiconductor.) Every now and again I was fortunate enough to come across some ECL based logic (ECL-Emitter Coupled Logic), the fastest logic family, which provided a bit of variety. I think the discrete component computers were more interesting to work on, although I was well entrenched in the Integrated Circuit era. The more interesting time was spent with small to medium scale integration with increasing levels of integration reducing interest. I did end up spending significant time with Large Scale Integration implementations. Large Scale Integration and implementation of Surface Mount technology contributed to reducing cost of systems and made it difficult to replace components. This led to component level repair of computers becoming impractical and costly in comparison to the cost of replacing modules or ultimately the whole system. I spent an increasing amount of time on the software side of the industry eventually ending up in management.

Following are extracts from three issues of the ATL company magazine called Tote Topics. When I started in the computer industry, it was well established, however still at a time when there were no personal computers and most people had never seen a computer. It was about 17 years after having started in the computer industry that I purchased my first PC and several more years till I had my first smart-phone. Prior to the PC, if I wanted to write a memo at home, with no access to the work computers, I had to use a typewriter. At work I would use an editor to create a text file as there were no word processors. If you wanted to create a large document, like a specification or a manual, you would use a mark-up language, of which HTML is an example. This made it easier to make changes to the document without reformatting everything.

I spent far too much of my life on deserted racetracks working on problems in the middle of the night and into the wee hours of the morning, unable to make any phone calls, as it not only pre-dated any mobile phones, it was illegal to have land-line phones on the track. I recall the problems the early systems analysts had introducing computers into workplaces which had no shortages of experts in the customer's business yet none of them had the slightest idea of what a computer was, what it was capable of or what a human interface with such a machine might look like. When computer systems were introduced, the people who were being inducted into computer operations were generally apprehensive about it. I well recall the common scepticism regarding their introduction that is reflected in the following article. When I was part of the introduction of computer based totalisators to the five major race-clubs in the Brisbane region, there was next to no knowledge of computers amongst the racetrack staff at all. More widely than this, Queenslanders in 1978 being rather parochial at the time, did not seem to me to have any knowledge of computers, bar the few people working in the industry. At an early tote operation, where the air conditioning was struggling to maintain a safe operating temperature for the totalisator system, the ATL branch manager suggested hosing the system down!

Go back to the index

Go back to the index

Go to the bottom of the page

Go to the bottom of the page

I am interested in the origin and evolution of the word computer. One possibility is that it derived from the Latin words Computus or Computare. One thing is for sure, its meaning has certainly changed particularly after the advent of digital computers. It is interesting that the first article below shows that at the time of writing the definition of the word computer, had a long way to go to reach the generally accepted meaning it has today. The writer, P.J.G. or Peter Gillespie, prefers to not use the word computer but the words, electronic totalisator, instead. Keep in mind that long ago the word computer referred to a job. You could be employed as a computer!

Following is an article in Tote Topics No.16 April 1968:

Electronic Totalisators I

During the last few years there have been several installations of a new type of totalisator, where the machine room contains several digital computers instead of the more familiar type of electromechanical adders. These "Computer" or "Electronic" totes are superficially quite different from the older types and their advantages and disadvantages have been the subject of much discussion. As always this has been based on quite a lot of information but also some mis-information.

In a number of articles, of which this is the first, a non-technical explanation of their characteristics will be given to endeavour to eliminate this "mis-information". Much more technical descriptions are available to anyone interested, but most people are not concerned with the "gory" details of gates and bits and buffers, flip-flops and program loops. These can safely be left to the engineers designing the system. What is required by the majority concerned with racing is a broad appreciation of the system from the point of view of the user. This it is hoped to give.

To anyone associated with Racecourses a number of questions immediately arise,

- What are these Electronic Totalisators?

- How do they differ from the older types in service?

- What systems are they suitable for?

- Are they a new-fangled gimmick or a major advance?

- Are they reliable?

and many others. The last question is usually, Should we have one?

What is a tote

To answer the first question, What is an Electronic Totalisator? we have first to consider the essential characteristics of any totalisator.

Shorn of all its appendages and complications, the heart or core of any totalisator is merely a series of counters or adding machines. For any given pool, there is one to count the bets on each horse or combination. This is the quintessence of the machine and the irreducible minimum beyond which it is impossible to go.

Of course any practical totalisator contains very much more than this. The additions, which necessarily complicate the whole system, are directed to two main ends. These are, firstly to provide better service to the betting public and secondly to protect the system from error as far as is humanly possible.

In the first case we must provide for a number of pools and a number of different values of bet. These must be available from a multiplicity of ticket issuing machines distributed throughout the course. The odds, calculated from the bets already placed, must be automatically calculated at frequent intervals and the display up-dated. When the race is over, the dividends must be rapidly calculated so they are ready for display and payout when correct weight is signalled. These, and many other features, are all directed towards better service to the punter.

The second group of complications arise from the necessity to ensure a virtually error-free operation. They are of intense interest to the operator of the totalisator, who usually has to foot the bill for any malfunction of his machine. They start with the complete checking of the bet for legitimacy of runner, pool, code, and possibly value. These must all be certified correct before a ticket can be issued. The checks continue, through the check of the horse totals by a grand total, right through to the check of the final dividend, and the complete accounting for the race which must be balanced before payout can begin.

So, even though a totalisator is fundamentally very simple, the practical realisation of a reliable machine is quite an extensive and complicated piece of mechanism. One, moreover which must be capable of quick and easy operation, adjustment and, if necessary, repair.

The Electronic Totalisator

The devices usually employed for the essential elements, these adders which are the heart of the totalisator, are mechanical or electromechanical counters. The Electronic or Computer totalisator uses a digital computer for this counting job. however as digital computers have such enormous calculating capacity they may be used to replace other portions of the totalisator also, and in addition to provide facilities not normally available with other types.

It should be noted that the word Computer can be used, quite correctly, to describe anything from a small group of relays to a full scale digital computer. It is used here in the latter sense only. Because Computer is liable to misinterpretation and misrepresentation in this regard, we prefer the term electronic totalisator as it is rather more precise.

The characteristic which distinguishes digital computers from ordinary calculating machines is their ability to carry out a whole series of calculations, according to a list of instructions, without human intervention. These instructions, called the program, tell the computer in the minutest detail what to do. They are normally stored away in the machine memory to avoid delay in obtaining the next instruction.

With this programming capability, it is obviously possible to store instructions on how to check and service a ticket issuing machine, or how to do the necessary calculations and even how to control the indicator boards. These are all, of course, in addition to the primary purpose of counting bets.

When all these facilities are added together we have the full scale Electronic Totalisator. The ticket issuing machines are all connected to a large switch, called a Scanner, which connects them through, one by one, to the input of the computer. The bet information keyed into any ticket issuing machine is checked, in its turn, by the computer and a signal sent back to print a ticket if all information is correct. The bet information is stored away in the computer memory with all other similar bets. Periodically, odds calculations are done on the stored information and the results are printed out on high speed printers and also posted on the indicator boards. These boards are controlled by the computer through a switching device called a Board Control Unit.

The betting Program is stored in the Memory and contains the step by step instructions for controlling the ticket issuing machines and the indicator boards, as well as calculating and printing out dividends and all race information. The whole system operates quite automatically, and human intervention is only required to stop and start various phases of the operation or put in information such as the list of valid runners or the winning numbers. This is all done through the keys and switches of the Totalisator Control Console, from which the whole operation is controlled.

P.J.G.

A Totalisator Control Console or TCC, mentioned in the previous paragraph, can be seen in an image above titled Bob Plemel and the PDP8 TCC. In the next article, the sound produced by the electromechanical totes is mentioned. A lot has been spoken and written about this. Engineers who worked on the electromechanical Julius tote systems, have said that they could tell certain faults with the system from the sounds emanated. Following is the second article in the series in Tote Topics magazine No. 19 July, 1968:

Ray Stone and another view of a PDP8 Tote

Following is an image of Ray stone, who worked for Automatic Totalisators Limited and also worked for the Digital Equipment Corporation, sitting in front of an ATL PDP8 based totalisator system. Ray Stone is Rob Stone's brother. I have included this image here as it shows some of the items mentioned above.

A device called a Scanner is mentioned in the section above titled The Electronic Totalisator. In the fourth and fifth racks in the image below are two Scanner front panels can be seen mounted immediately above the bench. They are black panels with two rows of status lights at the top. Additionally a Board Control Unit is mentioned and the front panel of one of these can be seen in the sixth rack, above the bench partially hidden by the CRO. The program being stored in memory is also mentioned above. As Ray points out below, this memory is installed in the backplanes, the wiring side of which is visible above the Paper-tape Reader/Punches in the first two racks. These Paper-tape Reader/Punches are the black looking panels in the mid section of these racks, one for each of the two PDP8 processors in this system immediately below the Reader/Punches. The left hand PDP8 processor has been pulled out of the rack on its runners to access the electronics.

The Wentworth Park PDP8 Totalisator at the factory

Following is information Ray provided:

This is a photo of me sitting in front of either the Harold Park or Wentworth Park system in the front room at Meadowbank during assembly and testing.

I have written on the back Oct/Sep 1970? The doors on the scanner cabinets are off and one 8/I ('A' machine) has it's drawer out to see the backplane. The cabinets have clear plastic film over the backplanes, to keep dust off.

Above the paper tape reader in each cabinet is the 4 row 8-16 kW memory expansion (fields 2 and 3). Then above that is the PC8i/PC08? paper tape reader-Punch interface. It had 2 rows of modules. Rob may have been working on that in the other photo you have of him on site. Webmaster's note: The photo I have is shown above titled "Rob Stone with Duplex PDP8 system at Harold Park 1970"

This is not a bad shot because it shows some of the detail of wiring and architecture of the system.

I have an 8I, I think I told you before but not all the power supplies (I don't think) to power it all, just the slide out 8k basic system rack shown here.

I have more than one paper tape unit I think up the back, and a 4k memory chunk from an 8I that I got from the salvage section of Digital in Maynard, Mass USA, in early 1974 while on training on the pdp-11 string of computers.

Electronic Totalisators II

The Characteristics of Electronic Totalisators

We have seen that the Electronic Totalisator is entirely different from the electromechanical types both as regards its equipment and its characteristics. Let us look at these differences in a little more detail, because in them we will find the essential features of the Electronic Totalisator, its place in the entire scene and even the basic reasons for its very existence.

In the machine room of an electro mechanical totalisator there is motion, constant motion, and noise. With betting in progress, the constant chatter of the escapements blends with the purring of the counters and the low rumble of the drives to give a quite characteristic sound. This sound, both in intensity and pitch, indicates to the experienced totalisator operator, even more clearly than his eyes, the state of the queues outside and the conditions around the selling houses. He scarcely needs a clock, so accurately is he able to predict from the betting pattern the time to the start of the next race. The equipment consists of row upon row of shafts and gears and escapement wheels and mechanical counters. At first sight it seems entirely mechanical as the electrical portions are buried deep inside.

With the smaller "counter tote" using electromagnetic counters, the pattern changes to that of a telephone exchange. There is the click of the relays and the clack of the counters as the bets pile up. One is still left with the impression of a mechanical device with the moving counters and manual operations.

However, the position changes entirely when we go to an Electronic Totalisator. The machine room consists of one or more rows of silent steel cabinets. Lights blink continually on the front panels of the cabinets indicating the progress of betting. Every ninety seconds new odds ripple along the boards and with a staccato burst the high speed printer spews out another page of updated odds and pool figures. Otherwise all is silent and the lights blink on. The operators move quietly about, occasionally flipping a switch or pushing a button to stop betting or calculate dividends or complete some similar, but normally laborious, task in the blink of an eye.

What was the reason for this change?, this quiet revolution that has taken place in totalisator technology? There were, of course, many technical reasons concerned with the state of the electronic art but the main factor, the most compelling reason, was economy. It was simply cheaper, as well as better, to make certain totalisators this way.

For many years there has been a trend, throughout the world, toward the more complex form of combination betting. Here the dividends are large due to the many combinations, but each combination requires an adder or counter with its associated equipment, and the overall cost can become very great. However, a digital computer is capable of storing a vast quantity of information relatively cheaply and this is the prime reason for its use. The more combinations there are to bet on, the more powerful the argument in favour of the Electronic Totalisator become.

Once having decided, for economy reasons, to use a digital computer, the many other advantages of the Electronic Totalisator come to the fore. In some cases, these even outweigh the original factors and become the prime reasons for its use. What, then, are the advantages, other than price, of installing an Electronic Totalisator?

The first point that comes to most people's minds is How old is it? Is it quite up to date? Is it this year's or, preferably, next year's model? Well, the Electronic Totalisator is all these and more. With the most modern integrated circuit computers it can almost be said to be the year-after-next's model. This is particularly so when the design philosophy of the totalisator is in the forefront of world thinking on this subject.

One of the most important characteristics of an Electronic Totalisator is its flexibility. To change the betting system or the pools, re-allocate the TIMs or make provision for other displays requires little or no alteration in equipment. Normally a program change is all that is required as far as the computer system is concerned. Changes necessary with other sections of the system, the ticket issuing machines and the indicators, are usually much greater than in the computer room.

Another important point about Electronic Totalisators is their speed of operation. This is very high and the cycle time of the computing system itself is measured in millionths of a second. However, the speed of recording a bet is determined by the speed of operation of the ticket issuing machine, and is in effect the time it takes a relay to close. The delay in servicing machines is thus kept to a minimum and, assuming a reasonable delay in issuing tickets, an electronic totalisator can efficiently handle about one thousand machines.

The speed of posting the display boards is also very high. The only really suitable type of indicator for an Electronic Totalisator is the lamp box because its speed is only limited by the selector relays. Any of the older, slower types of indicator requires a buffer store so that the computer system is not delayed. This increases the cost to the stage that they can become uneconomic. With lamp boxes it is possible to change about ten figures a second and, at this speed, the change ripples along the board and the new line of odds is completed while you watch.

Some people find the speed of calculation of dividends surprising when compared with the older system. The numbers of the placed horses are keyed in and the Compute Dividends button pressed. By the time you have raised your eyes to the board the dividends flash up. In case of a decision in doubt, all possible dividends can be calculated while waiting for the final results.

Off-course money can be simply added to the on-course pools. In this case the amounts are stored separately, as well as the combined total. Odds are automatically calculated from the combined pools, a result not possible except where the pools can be amalgamated. This is easy with a digital computer but difficult by any other means.

With a computer it is possible to produce much statistical and collated information on the betting that it is not practicable to produce in other cases. And with high speed printers, which are an integral part of any Electronic Totalisator, it is possible to print this information out very rapidly. Both totalisator owner and operator can benefit by these printouts and improve their organisational and maintenance procedures.

So the Electronic Totalisator, this quiet revolution in the totalisator art, is upon us. It has produced a change probably greater than any other single item in the history of totalisators. Its characteristics are new and powerful and strange. Most of them can be used to advantage and some of them are outlined above. However, some factors are so different that an entirely new approach is necessary and a critical examination of what is required of a totalisator must be made. Outstanding among these is the question of Reliability, with a capital R, and this, together with Maintenance and Construction, forms the subject of the third article in this series.

P.J.G.

Following is the third of the Tote Topics articles, which appeared in issue No. 20 in August 1968. It is interesting to read this very early view of digital computers and the comparison with electromechanical systems. I have often wondered why documentation of these early computer totes refer to printing the odds and pool figures at regular intervals, however I never thought that this was a means of data recovery as indicted in this article. With the rapid progress of these systems to handling many venues and far more diverse pools with increased runner combinations, this option would have quickly been rendered impracticable.

There is an image with this article which looks like a monochrome low resolution copy of the PDP8 totalisator system shown at the top of this page without the promotion text. As the image at the top of the page is in colour, where the article below refers to dark doors this should be translated to brown when relating it to the image above.

Another observation is that although I had not heard the term The Check On The Check, I worked for decades with the ethos which dictated The System Must Work from which the concept The Check On The Check stems. I did receive a quip from a non technical manager once, that in his opinion my philosophy required backups of the backups for the backup! Although I got a giggle out of this obvious exaggeration, opinions such as his, suggesting standards were ridiculously stringent, were frowned upon within the company's engineering departments. The company's customers were dogmatically persistent in conveying the message that downtime is intolerable. Contracts often had penalty clauses regarding the possibility of a downtime event.

One last comment. The following article mentions the longevity of the electromechanical Julius totes, referring to twenty, thirty and even more years. With the benefit of hindsight, I can now say that some of these systems operated for about half a century. Two of the big Julius Tote systems, Longchamps and Caracas operated for 45 and 50 years respectively.

Electronic Totalisators III

Reliability with a Capital R or The Check On The Check

Electronic Totalisators are so different from other types that it is not possible to apply to them the usual reliability criteria. We must, therefore, be very clear what we require in this line because the way in which it is achieved is so utterly different.

Ideally no equipment of any description should ever go wrong or give any trouble. This can never be completely achieved in practice, but with some types of equipment which are well designed and manufactured this ideal can be very closely approached. ATL Totalisator equipment is a case in point where the fault rate is extremely low. It is thus able to provide unfailing service to the punter and ensure that the owner and operator do not lose money.

To achieve these ends, two things must be done. Firstly, as mentioned above, the equipment must be designed and made as well as is humanly possible to reduce the fault rate to the absolute minimum. Secondly, precautions must be taken in the design so that the vital race information can never be lost, come what may. Let us look at these two points in turn and see how they are carried out both with electromechanical and electronic totalisators.

Excellence of mechanical design and manufacture of electromechanical equipment results in a low incidence of faults and also long life. To see that this is so it is only necessary to consider the ATL installations which are still giving excellent service after twenty, thirty and even more years of continuous work. There are many of them spread throughout the world. With electronic equipment, which is made by the large specialist manufacturers, it is, first of all, necessary to select the best available. If the overall reliability must be improved further, and this is frequently the case, then duplication and possibly triplication of the equipment is the answer. As well as providing extra equipment against the possibility of malfunction, the duplicate can provide another check against miscalculation or misreading of data.

By these means it is possible to produce an almost negligible fault rate. However, the financial consequences of any fault can be extremely serious and the second precaution mentioned above must be taken, to ensure that the pool information can never, never, never be lost. The way in which this has been done has given rise to the famous ATL phrase The Check on the Check. With electromechanical totalisators there are always several points from which the initial pool information may be independently obtained to check results, or in case of need. These points are all mechanical, such as counters, and virtually the only thing which could cause the loss of all information would be an atomic bomb!

With Electronic Totalisators the same type of counters are not used. The information is stored in the magnetic core memory of the computers and one cannot look at it and see what is there. However, an integral portion of any Electronic Totalisator is a high speed printer and in normal use the updated odds and pool figures are printed out at frequent intervals, normally between 30 and 90 seconds. Printed information, which can never be significantly in error, is thus always available.

Additional records may be made which are quite independent of the pools accumulated in the machine memory. The most usual type of these is a magnetic tape containing details of all bets. However, it takes some time to use such records which are mainly useful as a long term backup. It is also possible, as with other types of totalisator, to reconstruct the pools from the machine counters and the odds, but again this takes some time.

Hence it can be seen that the principle of The Check on the Check, i.e. the ability to obtain vital information from several independent sources, has been carried through, in its entirety, to the Electronic Totalisator. Due to the different type of equipment, the way in which it has been done is quite different but the result is just the same in completely protecting the punter and the operator against all possible types of equipment faults.

Maintenance

With an Electronic Totalisator all the equipment outside the machine room is familiar, and normal maintenance techniques apply. In the machine room, however, fresh techniques are required on equipment which is similar to many computer installations. Personnel to handle this equipment must still, of course, be thoroughly steeped in tote philosophy. So a new member has been added to the team. He is thoroughly versed in the micro and integrated circuits of modern electronics as well as knowing the effects of the remainder of the totalisator equipment on them.

Construction

Shown on the front page of this article is the control section of an ATL Electronic Totalisator using PDP-8 computers. The other items in the machine room, which are not shown in the photograph, are the two high speed printers, the Teletypes and the computer room indicator.

On the left of the picture are three Scanners followed by two Board Control Units with the two Totalisator Control Consoles on the desk in front of them. Of the remaining five cabinets, the three with dark doors house the computers and the other two the extended memories and the high speed readers and punches.

P.J.G.

The writer of the above three articles has signed P.J.G. I wrote to John Pickering, ex ATL Marketing Manager to see if he knew who P.J.G. was. John used to be responsible for the Tote Topics magazine and wrote the following:

Peter Gillespie was the chief engineer in charge of engineering at that time and the Tote Topics articles "Electronic Totalisators" were written by him. Peter lived in a big house in Mosman (one of the top areas in Sydney). He was very interested in promoting the totalisator and supported Tote Topics. He made models of the totalisator cabinets so we could present a photo of the configuration to suit each client.

John mentions above that Peter Gillespie was in charge of engineering. As Bob Plemel, mentioned multiple times in this page, was in charge of engineering in my time with the company, Peter Gillespie must have been one of Bob's predecessors.

Turf Monthly magazine May 1969

Latest tote equipment could revolutionise course betting

Following is an article from the May 1969 edition of Turf Monthly magazine with the above title. It is pertinent as it describes the outside or customer's view of the very systems being described in this page. It actually mentions the Hong Kong Happy Valley and the Georgetown systems as described and shown above. As I recall, Malcolm Mactaggert was the General Manager when I joined the company in 1977. Now to the article:

What is your main complaint when betting on the tote? Is it too slow to get a bet on? Do you have too many tickets if you want to place a big amount? Or perhaps the indicator boards that forecast your likely dividend are too inaccurate? Well, all of these problems and more would be solved if our race clubs decide to buy a new totalisator set-up that has recently been developed by Automatic Totalisators Limited.

According to the company, it even makes the tote installed by them at New York's famous Aqueduct raceway a few years ago look old hat. It has cost A.T.L. many hundred thousands of dollars to develop the present equipment, and they claim it is easily the most up-to-date of its kind in the world. And if anyone should know, A.T.L. should. They have installed their equipment on 235 racetracks in 28 countries throughout the world and are acknowledged leaders in their field. Their new electronic equipment is already in use at the Dover Downs racetrack in Delaware in the United States and they have also just exported one to Hong Kong for the Happy Valley track.

Representatives of the major Sydney and Melbourne race clubs have inspected one of the new systems at A.T.L.'s Sydney plant, but there is no indication that they will buy and this is a pity for poor Mr. Average Punter. Perhaps the cost is large, but race clubs today are getting plenty back from totalisator betting via the TAB, so they should surely try and encourage this type of betting on the course.

Mr. Malcolm Mactaggert, the General Manager of A.T.L., would not be tied down to a figure when estimating the cost of installing the new system on local tracks. He claimed it depended on too many factors. "However," he said, "it would be a figure that we feel the race clubs could afford."

Now, after that background, I should explain the workings and the advantages of this new totalisator system. For the technical man, it is an electronic totalisator using three PDP-8 computers. Webmaster's Note: Two of the three PDP8 computers mentioned are visible in the two racks on the right hand side of the image above titled The Happy Valley system being developed. The third PDP8 is in the rack behind Bob Plemel who is standing in the image. Its workings are such that it makes present Sydney and Melbourne course totes look more old fashioned than a T model Ford.

For a start you can go to a selling window and do the following-

- Bet in any denomination from 50 cents to $5000.

- Bet win, place, quinella, doubles or even forecast.

- Make an advance bet on a later race.

Possibly the best advantage of the system, though, is that within a fraction of a second of placing your wager it is recorded via the computer and the approximate odds on the various indicators around the course are brought up to date automatically. To call them approximate odds is really an inaccuracy as in several tests during my inspection of the equipment I found them to be amazingly correct every time. Thus, if a horse was showing 4/1 when betting stopped it paid exactly 4/1, or if a quinella combination showed 26.4/1 it paid exactly $13.70 for 50 cents.

Imagine, too, the advantage of being able to buy your quinella and double tickets at the same window as win and place tickets. At the Dover Downs track in Delaware, the A.T.L. equipment is geared to take seven different types of bets on any one race - win place (1, 2), show (1, 2, 3), doubles, twin doubles (4 wins on end), quinellas and exactors (a type of forecast betting).

The computers operating the system are so quick that dividends take less than a second to work out once the placings are known. In effect, if No. 8 wins from No. 4 and No. 3, an operator in the control room simply pushes 8, 4 and 3 in that order and all dividends from win to doubles come out instantaneously on a tele-printer-type machine. Hence, if this system was installed, all dividends could be displayed immediately correct weight was declared. This would be a big improvement on some of the present long delays for quinella and doubles dividends.

Although it works much more efficiently and much faster than present totalisator machinery, the new system is much more simple to operate. For instance, in the control room you need only two operators and most of the time they would be looking at each other with nothing to do. As a comparison, at Harold Park trots in Sydney, Automatic Totalisators use 10 people, plus two odds-calculators in the control room. Odds-calculators would definitely be out of work with the new electronic equipment.

The equipment needed for the control room of such a system is so portable that it would be feasible for, say, the two major Sydney clubs to purchase the equipment between them and have the control room equipment set up in a caravan-type vehicle to transport it between tracks. The new equipment in use in the United States is moved between the Dover Downs tracks and one at Georgetown when required.

According to A.T.L. engineers, the main advancement with the new system is that the computers were designed specifically for it and are an integral part of it. In some other systems, such as the one in operation at Aqueduct, separate computers were used and programmed to fit in with the tote. All of this does not mean that much to the average racegoer, but the fact that he would get much better service does.

The only things not electronically controlled with the new tote are the girls who punch the tickets. A.T.L. has examined the possibility of slot machines that give you tickets and change, but when you think of it, they would probably be slower than an experienced human seller.

In the accompanying picture there are eight "scanners" in the control room. Webmaster's Note: Six of the Scanners mentioned are visible in the six racks on the left hand side of Bob Plemel who is standing in the image above titled The Happy Valley system being developed. The remaining racks are off the left hand side of the image. Each "scanner" holds the bets of 64 selling machines, so even such a small, compact control could provide for over 500 ticket selling windows.

It was pointed out to me that even bookies would appreciate the new tote. With the 100 per cent accuracy of the odds-indicators, they could more easily estimate the chances of "laying-off" favourably on a horse they had overlaid. However, even though I am a supporter of the "bagmen", totalisator equipment such as this is surely another nail in their coffin.

I hope not, but it would certainly make great competition for bookmakers and it would be of a tremendous advantage to course punters - both big and small - if this equipment was installed.

There is more information on the PDP8 based totalisator systems scattered elsewhere around this website:

Front of an Automatic Totalisators product promotion card

Front of an Automatic Totalisators product promotion card

Above is an image of the front of a company promotion card relating to the PDP8 based totalisator systems. The contents of this can be read by clicking on the image at the top of this page, then scrolling down and selecting the thumbnail of the image above.

For a closer look at the PDP8 system at Harold Park, click on the image at the top of this page, then scroll up past the section on Miscellaneous Images and select the thumbnail of the vertical oblong image with associated text starting A Raceday Control Console at Harold Park 1958.

There is a larger image of the PDP8 based totalizator in Georgetown America, shown earlier in this page, with additional information. Click on the image at the top of this page, and scroll down to the bottom of the page and select the Next page option from the Nav Bar at the bottom. Scroll down and select the image thumbnail of the image of the Georgetown system shown above titled Probably the Georgetown totalisator. The required thumbnail, has associated text starting A PDP8 based totalisator computer room...

- Thanks to Bob Plemel for the images titled The Hong Kong PDP8 Totalisator System in the Meadowbank Factory and Bob Plemel and the PDP8 TCC and the information he provided on the Happy Valley project.

- Thanks to Neville Mitchell for the image of the Georgetown PDP8 totalisator and his recollections of the PDP8 systems.

- Thanks to Max Burnet and Peter Watt for the image titled The PDP8 Backplane. and to Max again for his comments.

- Thanks to Rob Stone for the image titled Rob Stone with Duplex PDP8 system at Harold Park 1970.

- Thanks to Peter Collier for providing the three Tote Topics magazines with the Electronic Totalisator articles, which are in his electronic Tote Topics magazine archive.

- Thanks to Chris Robertson for the image titled Front of an Automatic Totalisators product promotion card.

- Thanks to William Johnson for his comment.

Comments and suggestions welcome to

totehis@hotmail.com

Probably the Georgetown totalisator

Probably the Georgetown totalisator

Bob Plemel on the left and the PDP8 TCC

Bob Plemel on the left and the PDP8 TCC

PDP8 Backplane Photo by Max Burnet and Peter Watt

PDP8 Backplane Photo by Max Burnet and Peter Watt

Go back to the index

Go back to the index

Front of an Automatic Totalisators product promotion card

Front of an Automatic Totalisators product promotion card