This technology history page contains a photograph, which is one of several belonging to the photo gallery pages, which are part of several pages relating to the invention of the world's first automatic totalizator in 1913 and Automatic Totalisators Limited, the company founded by George Julius in 1917 to develop, manufacture and export these systems.

Early Adder Manufacturing Adder Assembly Section

There is irrefutable evidence that the photograph shown in the first image below, was taken inside the factory at Alice Street Newtown in Sydney. The windows seen open in the far corner of this part of the factory are consistent with the windows seen in the Earliest Staff Photograph taken outside this factory which can be seen in the third image prior to this one in the Photo Gallery accessible by clicking on the image below and scrolling up and selecting the image thumbnail associated with the staff photo. The roof is corrugated iron as in other images of this factory and the shape is long and narrow, in keeping with a 1949 aerial survey photograph, which shows the major part of the factory being long thin buildings with A-frame roofs. The 1949 aerial survey photograph can be seen in other pages related to this factory in the Photo Gallery of this website. Additionally the adders being assembled in this image are for the Longchamps installation, which as described below means this image must be of a section in the Alice Street Newtown factory. It is quite clear that the items being assembled here are large adders. It does not appear to be a production line as each of the adders being assembled seems to be in a similar early state of assembly.

More after the image...

Click on the image to go back to the Photo Gallery

The photographers stamp on the photograph reads HALL & CO., Commercial Photographers, 20 HUNTER STREET, SYDNEY.

There are nine overhanging assemblies in each of the adders on the long row of assembly tables, on the right hand side of the image above. They look like pairs of fingers reaching out perpendicular to the left hand top support bar of each adder and protruding left of each adder in the direction of the line of men working on them, the line starting from the centre of the image and ending at the far wall near the top right corner. These pairs of fingers are easy to see on the nearest three adders on the right hand side of the image and the men working on these adders have their right hands on or near these pairs of fingers. A small rod will be inserted between the tips of each pair of these fingers, which act as fulcrums for the storage screw locking levers. These overhanging assemblies are typical of the Longchamps adders. Nine of them can be seen in the image of a complete Longchamps adder below, above and rearward of each of the nine silver pulleys right across the front mid height section of the adder. Back to the image above, these overhanging assemblies are at the front of the adders, near the men working on them and on the right hand side of the nearest adder assembly tables, you can see the nine rear end support pillars standing which will support the rear end of the nine storage screws yet to be installed. The storage screws are long tubular devices which are a mechanical form of memory described in the Brough Park Newcastle Upon Tyne 1936 section pages accessible by clicking on the image above and scrolling up to that section. Some of the nine storage screws are visible in the complete adder image below, behind the nine pulleys across the front mid section of the adder.

On the nearest two adders in the image above, underneath the finger like assemblies to the left of the supporting bar, you can see some of the the storage screw drive pulleys already in place clearly indicating they are Longchamps adders, as I have not seen this drive arrangement in any other adders. These drive pulleys can be seen in the image below across the front of the adder, two larger pulleys on the left hand side with seven smaller pulleys on the right. All the men working on the two right hand row of tables as opposed to the long heavy row of benches on the left, are working on assembling the Adders. The image below shows one of the Longchamps adders fully assembled and installed in the Longchamps machine room. There is a full sized version of this image in the Photo Gallery of this website and the associated page contains a description of the adder. To view this, click on the image above, scroll to the bottom of the page and select the Previous page button in the navigation bar, then scroll down in the index to the section with a title starting Longchamps Paris 1928 ... and finally select the image thumbnail corresponding to the image below. Whilst in that part of the Photo Album, have a look at the first image in the Longchamps Paris 1928 ... section with the associated text starting with The adders in Longchamps France... to get an idea of how many of these adders were in the Longchamps Machine Room. I do not know if I have convinced you dear reader, that the adders being assembled in the image above are the Longchamps adders like the one shown in the image below, however I am totally convinced. As the Longchamps system for France was unique, in that it was the largest Julius Tote system installed at the time supporting a minimum of 273 terminals requiring the largest of adders by far, only to be later surpassed by the White City London Julius Tote with 320 terminals utilising an obviously different model of adder, I have not seen any evidence that the Longchamps type of adders were used in any other installation.

Additionally regarding Longchamps, there is what looks like an empty milk bottle standing upright on top of the first complete bench visible on the left hand side of the image above, that does not appear to have anyone working at it. Lying flat on the top of that bench to the left of the milk bottle is a rectangular top mounting panel of a J5 TIM (Ticket Issuing Machine). This is the type of TIM used at Longchamps, of which there were 273. By zooming in you can make out the metallic 120 degree or so arc, that the runner selector handle slides over spanning across the nearest corner of the J5 top panel. This arc contains locator pin holes that are only just visible on a higher resolution image, that a locator pin in the runner selector handle engages once the correct runner has been selected. Additionally the coat seen draped over the near corner of this bench is lying on top of another J5 TIM that is in a much more advanced state of assembly. Diagonally across the bench behind this J5 on the far side near the man standing in a dark coat and facing the camera, another J5 TIM top panel can be seen. This J5 is obscured by the triangular support pillar for the drive shaft seen running above and along the length of the bench. This third J5 is also in a much more advanced state of assembly than the first. Presumably this drive shaft supported above the table is used for driving tools or activating completed TIMS for initial testing. This seems to be the only bench dedicated to J5 production in this assembly workshop. All the other benches in the same row of more substantial benches seem to be dealing with TIM or Adder component parts. As the majority of J5 TIMs for the Longchamps installation were built in France under supervision, it probably explains why only one bench in this image has J5s on it and no one is working at it. The J5s on this bench are probably a few being built for testing purposes of the Adders and the front end systems containing electromechanical Time Division Multiplexers or Scanners as they were called that interfaced the two.

I am convinced that both the Adders and TIMs in the image above are being built for Longchamps, a system that commenced operation in 1928. As the photograph was taken by Hall & Co in Sydney, I think it is safe to write that the photograph shown in the image above must have been taken inside the Alice Street Newtown factory, as this factory had been in operation since at least 1917, probably earlier, and the Alice Street Newtown factory address continues to appear in the Sydney phone books until November 1933. In 1934 the Sydney phone book gives the address of the Automatic Totalisators Limited factory as Chalmers Street in the Sydney CBD, a move that took place at a time when the Longchamps system had been operating for something in the order of 5 years meaning the Alice St Newtown factory was the one during the whole Longchamps project.

As the image above shows the Adders and TIMs being assembled for Longchamps racecourse in Paris, France, I have included the following Trove archive Newcastle Morning Herald and Miners' Advocate article, which demonstrates the significance of the French contract for Australia, which involves multiple racetracks. It is the largest Austral-French commercial transaction at the time.

Citation: 1926 'TOTALISATOR FOR FRANCE.', Newcastle Morning Herald and Miners' Advocate (NSW : 1876 - 1954) , 22 March, p. 5, viewed 20 May, 2015, http://nla.gov.au/nla.news-article137516504

TOTALISATOR FOR FRANCE

Universal Automatic Totalisators, Limited, Sydney, has contracted to instal at Longchamps totalisator machines of the type used in Sydney.

At first they will be operated by Australians to allow of a French staff being trained. This, together with the contract signed by Mr. Bethell on behalf of the same company last month to instal totalisators at 16 French racecourses is the largest Austral-French commercial transaction yet effected.(Emphasis added)

The French order meant considerable design work, as now, for the first time, the Adders were to be divorced from the Indicators. The Adders had to have a capacity of a minimum of 273 Ticket Issuing Machines through a Distributor connected to one Escapement Wheel, over 35 Escapement Wheels where needed on each Adder. The Adder design was a feat of mechanical engineering, all values and transfers being mechanically linked. The Ticket Issuing Machine design also was a remarkable piece of engineering and saw the introduction of a machine to sell both Win & Place tickets from the one machine. This was a big step forward and proved to be one of the main features for many years to come. The equipment for Longchamp was manufactured in the factory at Alice Street, Newtown, N.S.W. except for the Ticket Issuing Machines, which were made in Paris under supervision.

Frederick Wilkinson, who was the Automatic Totalisators Limited State Tote Manager and worked for the company for 30 years including the duration of this factory and the following one in Chalmers Street in the city, lived in Paris for 4 1/2 years working on the Longchamps project according to his son Rudolph Wilkinson. Rudolph also indicates that the Longchamps system was one of several to be installed in France as indicated above and that Frederick married Dorothy Watt during his time in France.

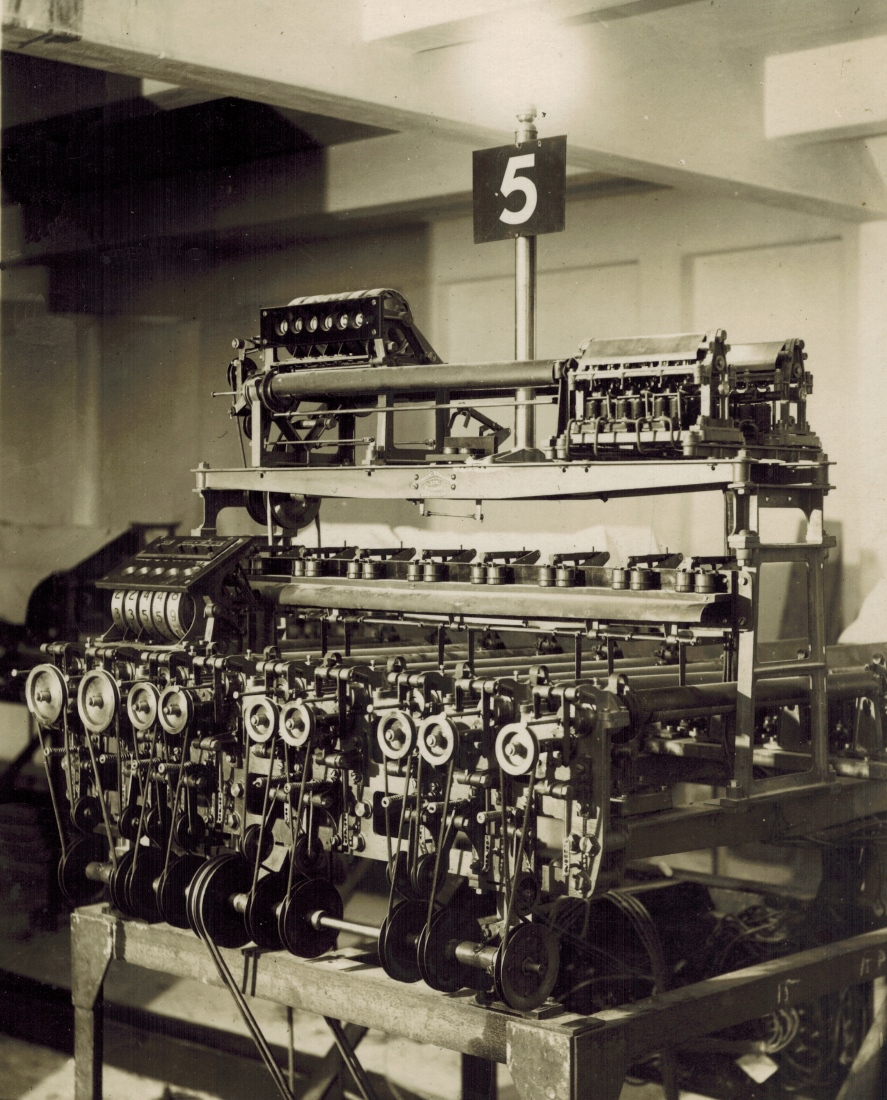

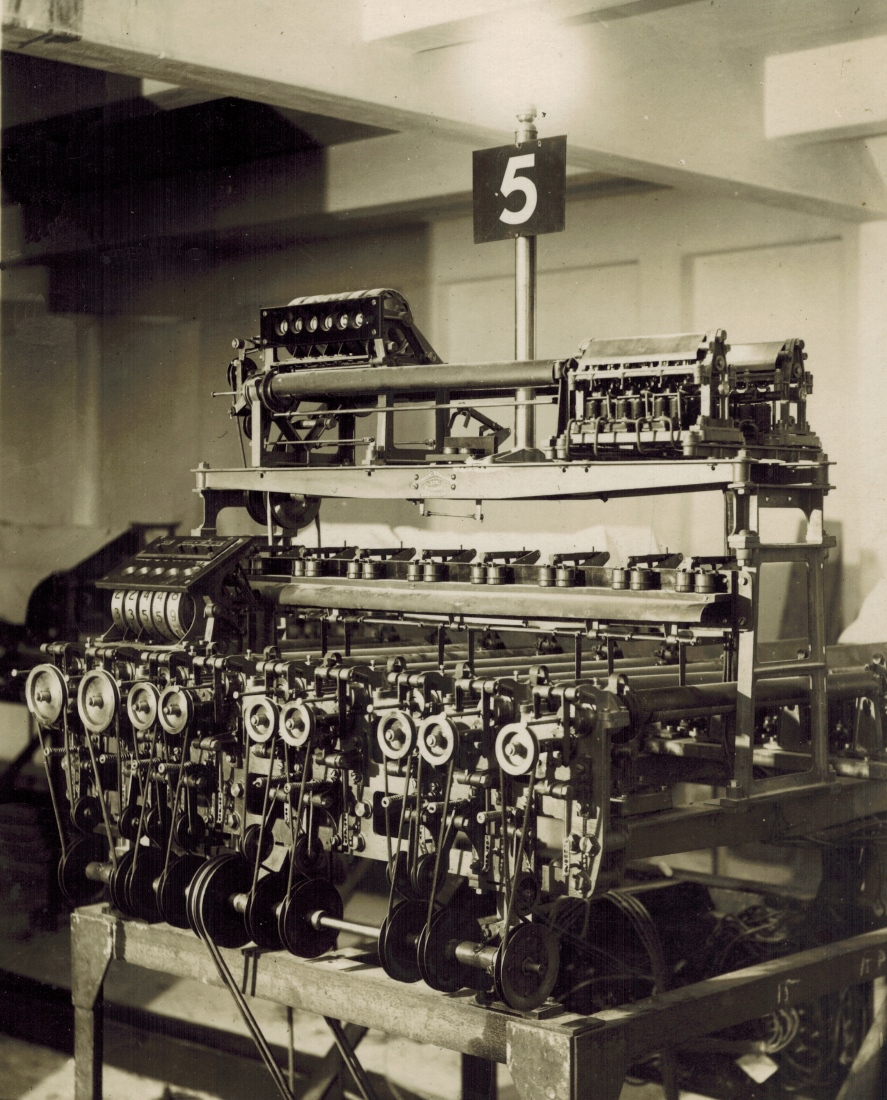

A Longchamps mechanical shaft Adder

The pulleys mentioned as being visible in the Adders being assembled in the image at the top of this page, are seen in the image above as the facing nine shiny pulleys, half way up the adder, which are above the row of black drive shaft pulleys. There is a good view of one of the constituent shaft adders and its associated storage screw in this image. The horizontal tubular device, that crosses the post with the number 5 on it, at the top of the Adder, is a storage screw. The right hand end of the storage screw is attached to an assembly that is an electromechanical shaft adder. There is a second storage screw and shaft adder behind the one visible at the top, which obscures the one behind. The main thing in view of this visible shaft adder at the top are some of the escapement mechanism solenoids which are activated by impulses from the TIMs (Ticket Issuing Machines) via the scanners, which today would be called TDMs (Time Division Multiplexers). The top of the shaft adder where the adding shaft is with its escapement wheels and epicyclic gears, is not in view as it has a permanent dust cover over the top. There are 9 storage screws and associated shaft adders in the equipment mounted below this level of the adder, which are mounted perpendicular to the one on top, with their associated 9 shaft adders at the rear of the assembly out of view of the image. The number 5 on top of the post indicates the runner number for which this complete adder is accumulating bets.

As with other images of these early factories, the image at the top of this page reveals how primitive working conditions were in those days. It is a long time to come before people start to think about posture and OH&S issues in general. There are many heads craned downwards, it gives me a headache looking at them! I do not think that any of the workers in this photograph, or any other workers of the time or their management would have considered the limited body positions that a worker can assume while standing without causing health problems or the considerable muscular effort keeping the body upright reducing blood supply in loaded muscles. Something in the order of half a century had to elapse before industry started to take these concerns seriously, driven by the cost of non compliance and even then there was resistance to the adoption of OH&S in the culture of organisations.

The floor in the bottom left of the image of the factory at the top of this page, looks as though it has a foundation of bricks overlaid with something like bitumen. The floor looks very old and as if it has had significant wear, as the bitumen like surface has a significant area where it has peeled off, leaving the bricks exposed. Perhaps it used to be a road! The larger benches on the left are of a solid purpose built construction and look like they have had a considerable working life. The assembly tables the adders are on seem to be a quick construction made out of the type of wood used for packing crates. These are probably a temporary construction to accommodate the large number of adders that had to be manufactured for Longchamps. These temporary Adder assembly tables were probably intended to be discarded after the Longchamps project was completed. The long exposure time of these old photos is evident, as a couple of the people in this image have moved during the exposure time causing them to appear blurred. This is particularly evident with the man working on the third Adder in the right hand row of adder tables where it seems there are three distinct exposures as he cranes his head towards the Adder. There is silver nitrate blemishing visible mainly in the bottom right of the photograph, not bad really considering that this photograph was in the order of 90 years old when it was scanned.