This technology history page contains a photograph, which is one of several belonging to the photo gallery pages, which are part of several pages relating to the invention of the world's first automatic totalizator in 1913 and Automatic Totalisators Limited, the company founded in 1917 to develop, manufacture and export these systems.

Copyright © 2015 Email - totehis@hotmail.com

A J11 TIM

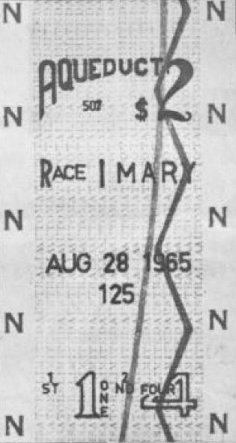

This is an image of a J11 TIM (Ticket Issuing Machine). Neville Mitchell the best Automatic Totalisators historian I know recollects the following in an audio tape he made for the Powerhouse Museum: The J11 was a highly successful machine that was dedicated to the North American market and it kept Automatic Totalisators in business for many years on its own. The production levels for that were enormous. Webmaster's note: The system at Aqueduct Racetrack in New York City alone had 550 of these TIMs.

Following is an observation from Chris Robertson, the most informed punter on the subject of totalisator systems I know. He suggests the J10 is more boring to operate than the J8. The J10 is similar to the J11 shown here, with a different button arrangement: Swinging the machine's dial looked a lot more fun than pushing buttons on the J10. More after the Image...

Click on the image to go back to the photo gallery

This is an Automatic Totalisators company Photograph

The J11 Ticket Issuing Machine

Following is an article in Tote Topics Magazine No. 3 Dated March 1967. The description here is slightly different to the J11 in this image probably due to the article relating to the earliest version of the machine. In addition different customers have different requirements. For instance, the article below describes a J11 which has a show pool which the machine in the image does not have, however it does also support the Qinella pool and more ticket values. Neville Mitchell wrote: Over the years there was many J11 models as we adapted the machine to the customers requirements.

A new type of ticket issuing machine was required by the New York Racing Association for installation at Aqueduct. It had to be of the most modern design with fast selection for use with digital computers. Push Button operation was necessary for fields of 12 starters on Win, Place, Show and Daily Double Pools. In addition it had to be light in weight and as compact as possible.

This sounds like a pretty tall order when combined with a tight time schedule. However, nothing daunted, A.T.L. delivered the goods on time, the goods being type J11 ticket issuers.

Description

The push button keyboard is colour coded, and has two rows of horse buttons numbered 1 to 12. Separating these two rows are buttons for "Win", "Place", "Show" and "Test", as well as an "ON" lamp. The upper row of horse buttons is for Win, Place and Show Pools and first leg Daily Double. The lower row is for the second leg of the Double.

To sell any ticket, two buttons have to be pressed, the cycle being initiated on depressing the second button. Issue of a ticket is almost instantaneous. All buttons are mechanically locked when depressed and reset electrically at the end of the cycle. They are guarded against "teasing" by a special device. A plastic diaphragm protects and seals the switch contacts against accidental spillage of liquids on the keyboard.

The issuer is connected to the totalisator system via two quick connect multi-pin plugs. The output is coded to reduce the number of connections required, the coding being done with a diode matrix on plug-in boards for ease of changing.

The machine is housed in an all-steel case finished in texture baked enamel. It is provided with carrying handles and roller supports to suit the installation runners. The cover is polished stainless steel, is quickly detachable and may be locked with a key. Through an aperture in the cover may be seen a non-resettable counter which indicates the total number of tickets sold.

Internally the machine is built up on die cast and machined alloy castings. All wearing parts are hardened and ground. The main rotating shafts are supported in sealed ball races, the remainder running in self-lubricating bearings for long life.

The machine now incorporates a patented, automatic ribbon feeding and re-inking mechanism which ensures uniformly printed tickets. This unit is fed by a quickly-removable felt reservoir roller which needs recharging only at intervals of about 50,000 tickets. The short, endless silk inking ribbon requires no service and its life is very long.

The machine draws paper from a 12 inch diameter roll which is sufficient for 6000 tickets. Any type of security overprint can be provided. The paper is fed into the bottom of the machine, there being no need to remove the cover.

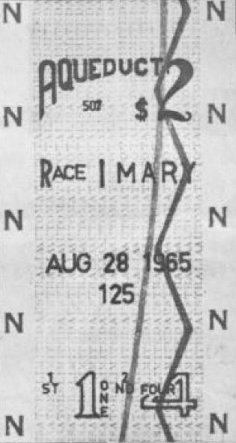

The tickets are 2 inches wide and 3 5/8 inches long and, as shown in the illustration, have the following details printed on them by the machine. Club name, ticket value, selling window number, race number, code, date (Day Month Year), meeting number, pool, horse number or numbers and leg designation for doubles horses.

Illustration of the J11 ticket

The race code barrel is quickly removable for storage in a strongroom between meetings.

The ticket issuing machine is 16 inches long by 17 inches wide by 10 inches high, weighs 67 lbs. and consumes 0.6 amps at 50V D.C.

Experience with the machine over a full years operation has shown it to be very reliable and unusually free from trouble. The faults, mostly minor, which inevitably occur with a new machine have now been eliminated and this issuer can be enthusiastically recommended as the most up to date, computer oriented, push button operated ticket issuing machine available in the world today.

This article is signed A.G.

Webmaster's note: I have heard many a time from salespeople that if anything is going to go wrong it is most likely to be during a presentation or equipment demonstrations. Following is an example of this principle relating to the J11 from Neville Mitchell:

I was involved with the early J1,1 in that I was then a detail draftsman, being mentored by Peter Rolls and being trained in all aspects of the emerging computer tote system for the NYRA Webmaster's note: New York Racing Association. There was a tight group of men who designed the J11. The team was led by George Klemmer, with mechanical engineers Allan Grey and Allen Street Senior and design draftsman Bill Bryant. Given the NYRA specification, the prototype evolved rather quickly once the design criteria was determined. Aided by the expertise of the ATL Tool Room the first machine was demonstrated to the board and NYRA in Meadowbank.

I had assisted Peter Rolls with setting up the J11 in the board room. Moments before the board members and the NYRA people were to be shown the machine, Peter with his Fickle Finger of Fate, locked the keyboard up. No fiddling with it would release the keys. We took the keyboard out and studied the circuit. In a few minutes, George Klemmer found a feed back circuit that was causing the lockup. A IN4004 diode was quickly inserted and with a very nervous group returned to the boardroom with the circuit board. No one ever knowing of the panic that had just occurred. Like most ATL ticket machines the J11 in the long run, went on working into oblivion caused by the relentless march of technology.

Webmaster's note: The J11 was the first of the TIMs built for a computer totalisator. All the predecessors were used with the Julius totes which were electromechanical. Following is a comparison between this TIM and its predecessors from Neville Mitchell.

When I think about J11s they were very similar in function to all the previous Julius ticket machines. The operating computer system using J11s does exactly the same as a Julius electro mechanical tote machine! A J11 ticket machine generated a BID which is the same signal as W or P in a Julius tote to initiate a bet. The next step is to read and verify the DATA race, runner, pool and ticket value. Same as Julius, the next signal is CONFIRM, which TRIPS the Issuer causing a ticket to print. There is another signal REJECT, which is delivered if there is any fault with the data or an Issuer internal fault. This was not an automatic function of a Julius TIM. A faulty machine had to be RESET via a manual push button on each TIM.

To read more about the Aqueduct system mentioned above, which was the world's first electronic totalisator, have a look at Aqueduct in the Automatic Totalisators in America chapter.

- Thanks to Peter Collier for the copy of Tote Topics Magazine No. 3.

- Thanks to Neville Mitchell for the image of the J11.