This technology history page, significant in the history of computing that contains a photograph, which is one of several belonging to the photo gallery pages, which are part of several pages relating to the invention of the world's first automatic totalizator in 1913 and Automatic Totalisators Limited, the Australian company founded by George Julius in 1917, to develop manufacture and export these systems.

Copyright © 2018 Email - totehis@hotmail.com

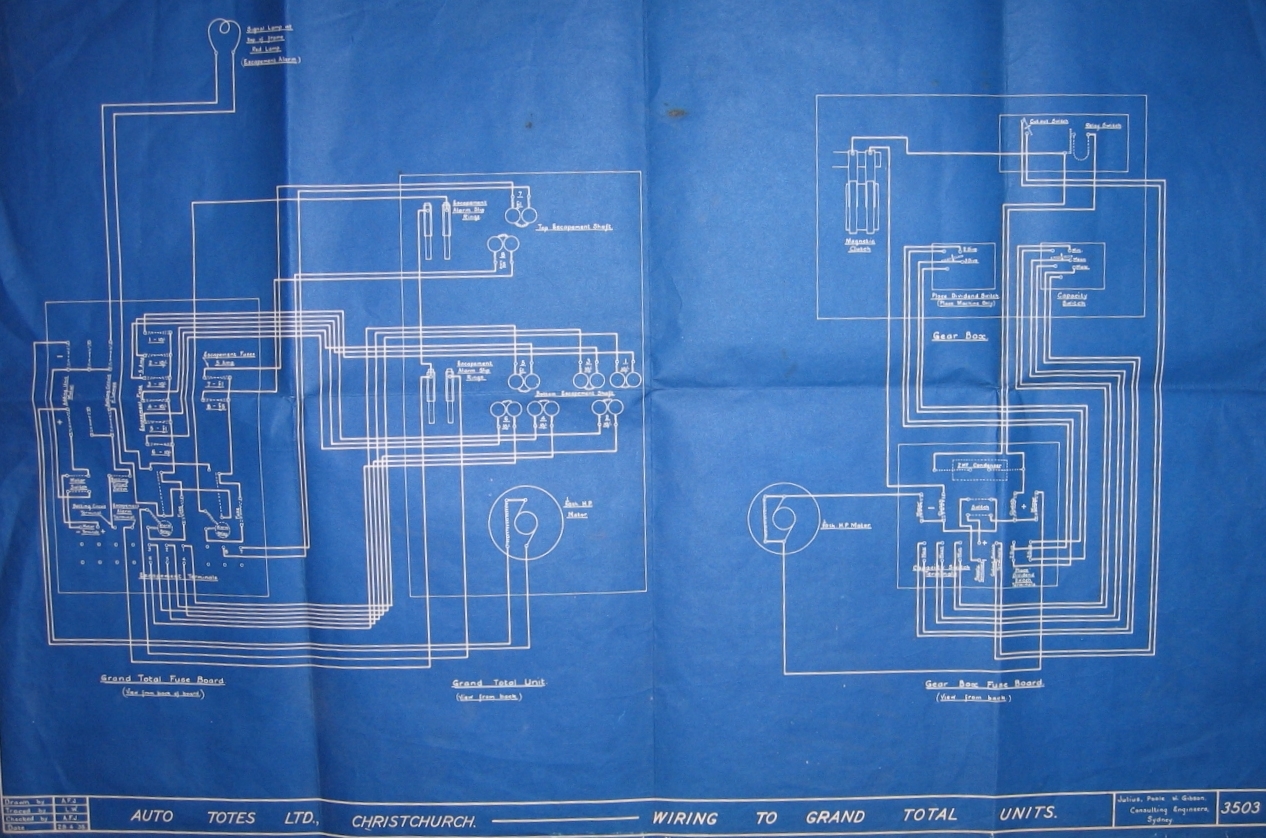

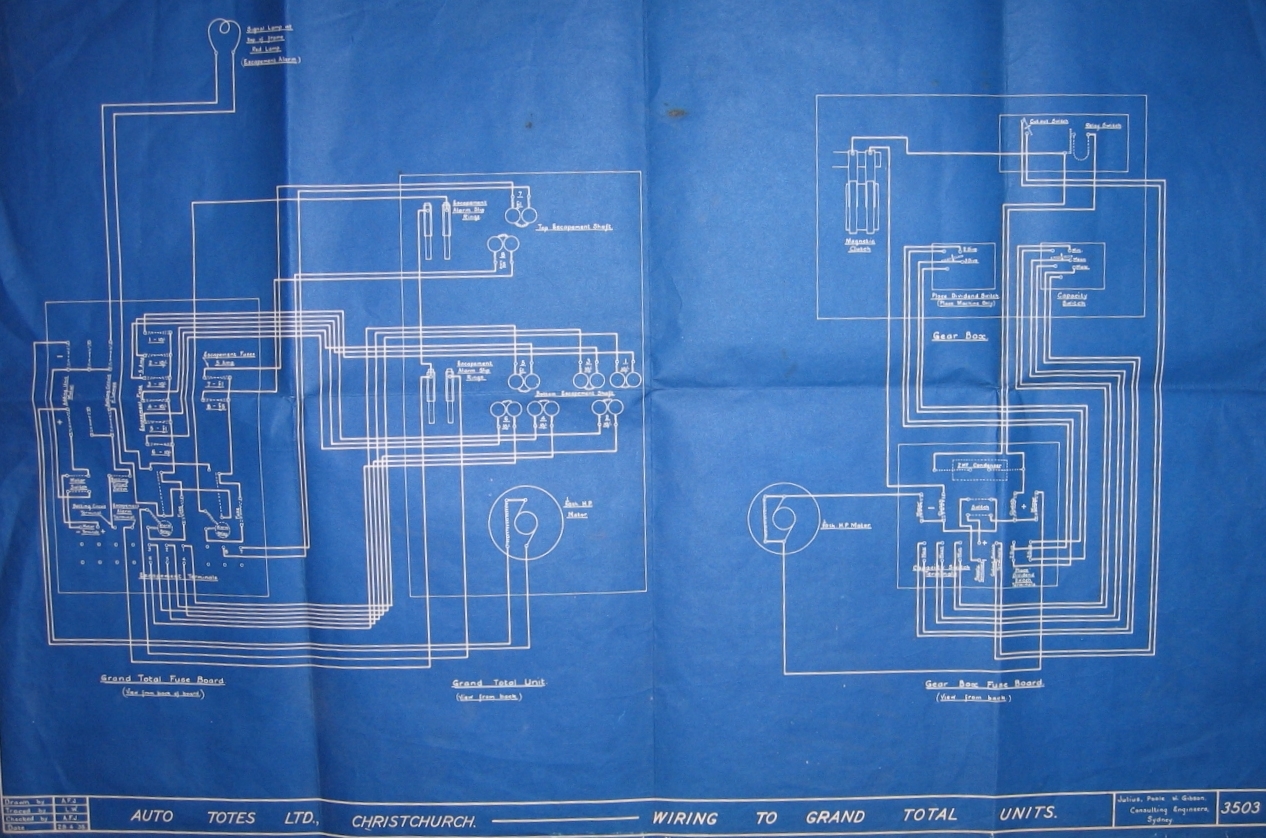

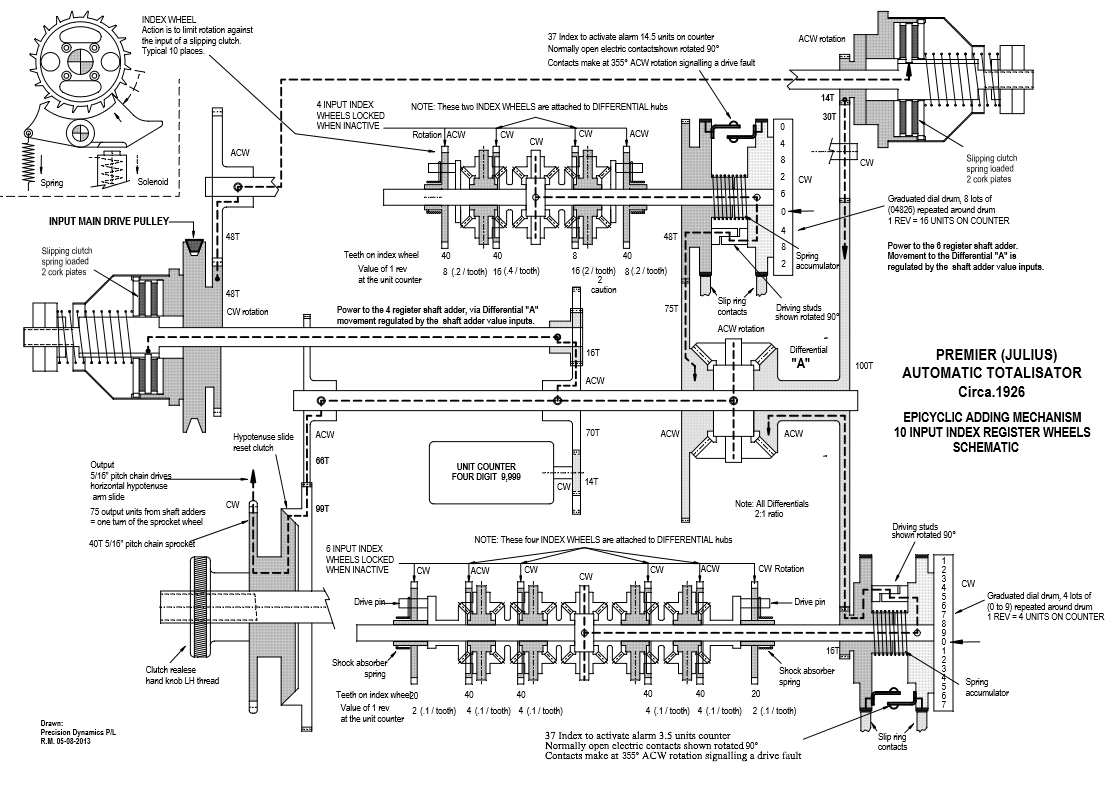

Historic Technical Drawing Blueprint

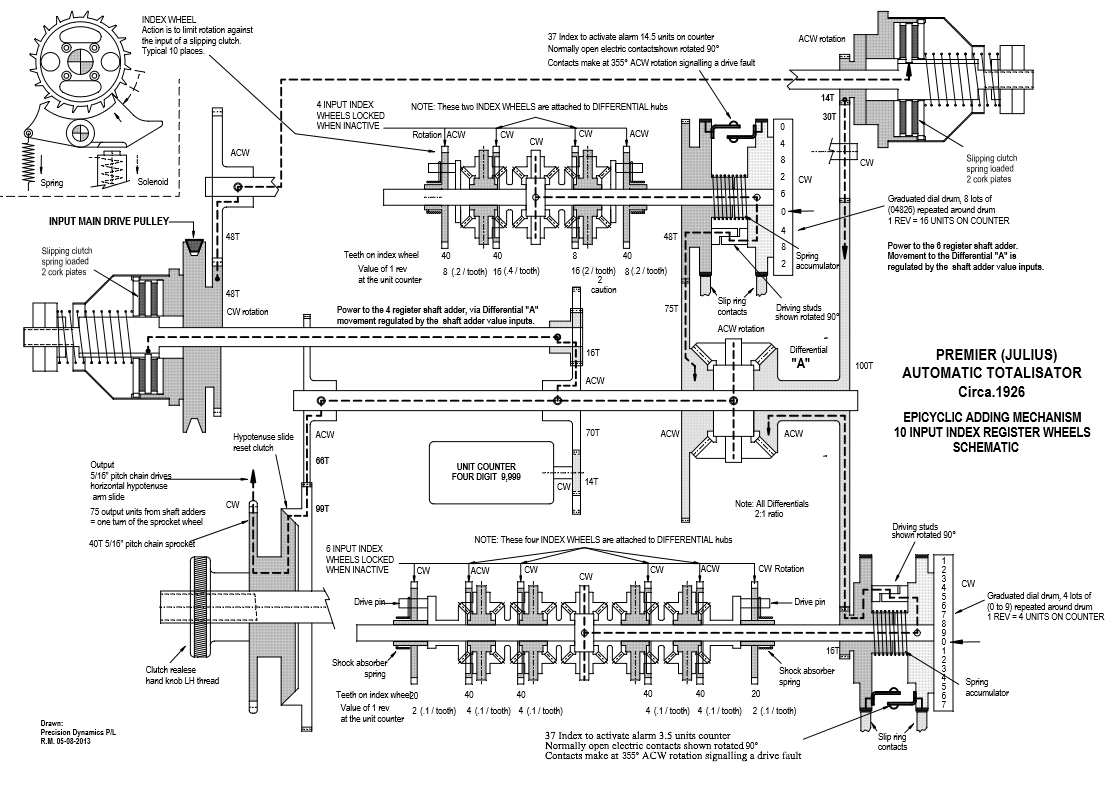

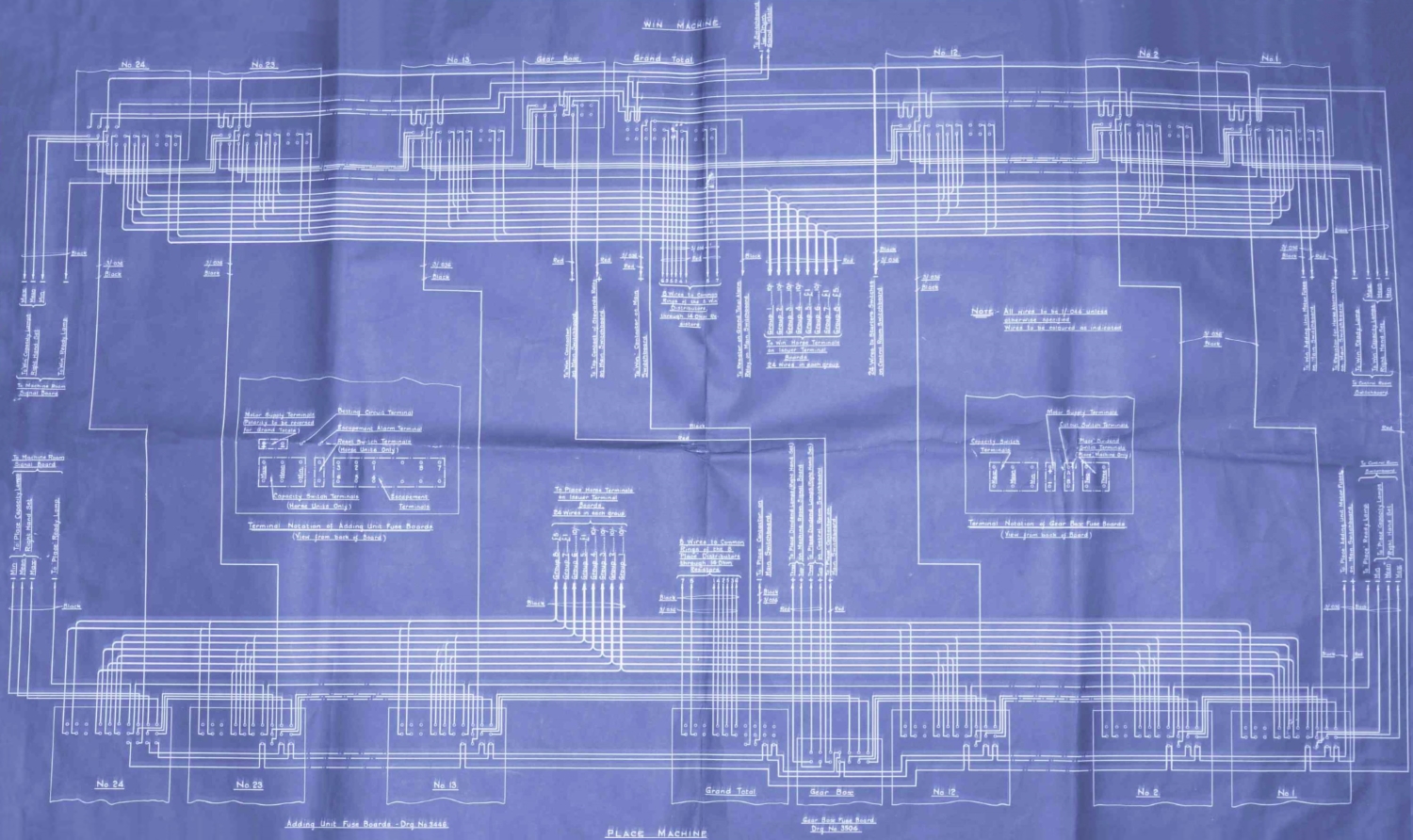

In 2007, I visited Riccarton Racecourse whilst in Christchurch and was very surprised to find a Julius Tote Barometer Indicator in excellent condition on the side of a building on the racecourse. I was further amazed to find that the Julius Tote mainframe that drove this indicator was still present in the building. I informed Professor Bob Doran from Auckland University of this and he organised a visit to see this system and identify what was still present and examine research and document it. As a result of this, Bob sent me many photographs of the equipment and some of the documents he found there. I never cease to be amazed how Bob, so entrenched in the future, having been Principal Computer Architect at Amdahl Corporation, designing tomorrow's computer systems and later a Professor working on educating the next generation of computer engineers, could be so passionate about the past and the path taken to arrive at the present state of computer technology. One of the documents he sent me is titled Automatic Totalisators Limited Description of Electrical Circuit Diagrams. In this there is a page titled LIST OF CIRCUIT DIAGRAMS DATED 15/5/1935. There are several circuits described in this document and I have included all the text from it in this page. Two Julius Totalisator installations were performed in Riccarton, the first in 1921 and the second in 1935 to which the company document describing the Electrical Circuit Diagrams belongs. The two Automatic Totalisators Limited Blueprint Drawings presented in this page, starting with the one immediately below, also belong to Prof Bob Doran's collection, relating to the 1935 Riccarton Julius Totalisator.

Click on the image to go back to the Photo Gallery

If you arrived from navigating the website, use the navigation bar at the bottom of this page.

The Blueprint Drawing above was produced by Julius Poole & Gibson, George Julius' engineering consulting company.

I find the blueprint drawing above and the one further down this page of particular interest for two reasons. Firstly the fact that they are blueprints. I recall there being a proliferation of blueprints in the AWA Print Room located at the North Ryde factory in Sydney in the early 1970s. This was a once common means of reproducing engineering drawings. Despite Blueprints becoming so common that the word became part of the English language, they now seem to have disappeared into antiquity as I have not seen any blueprints in decades. Secondly, the drawing below titled Julius Poole and Gibson blueprint, as well as the one above, were produced by Awdry Julius, George Julius' son, who was working for his father's other company Julius Poole and Gibson. I determined this from the drawing identification box in the bottom left corner of the drawing below as well as the identification box of the original image of the drawing shown above. I have not presented the whole original image above, because of the damage to the drawing and I have performed repair of the original image in what is presented above. This identification box in the Julius Poole and Gibson blueprint drawing below also has a creation date, which like a lot of the writing in this image of the blueprint drawing is blurred, however I am quite confident it reads 29 4 34 which is 29th April 1934.

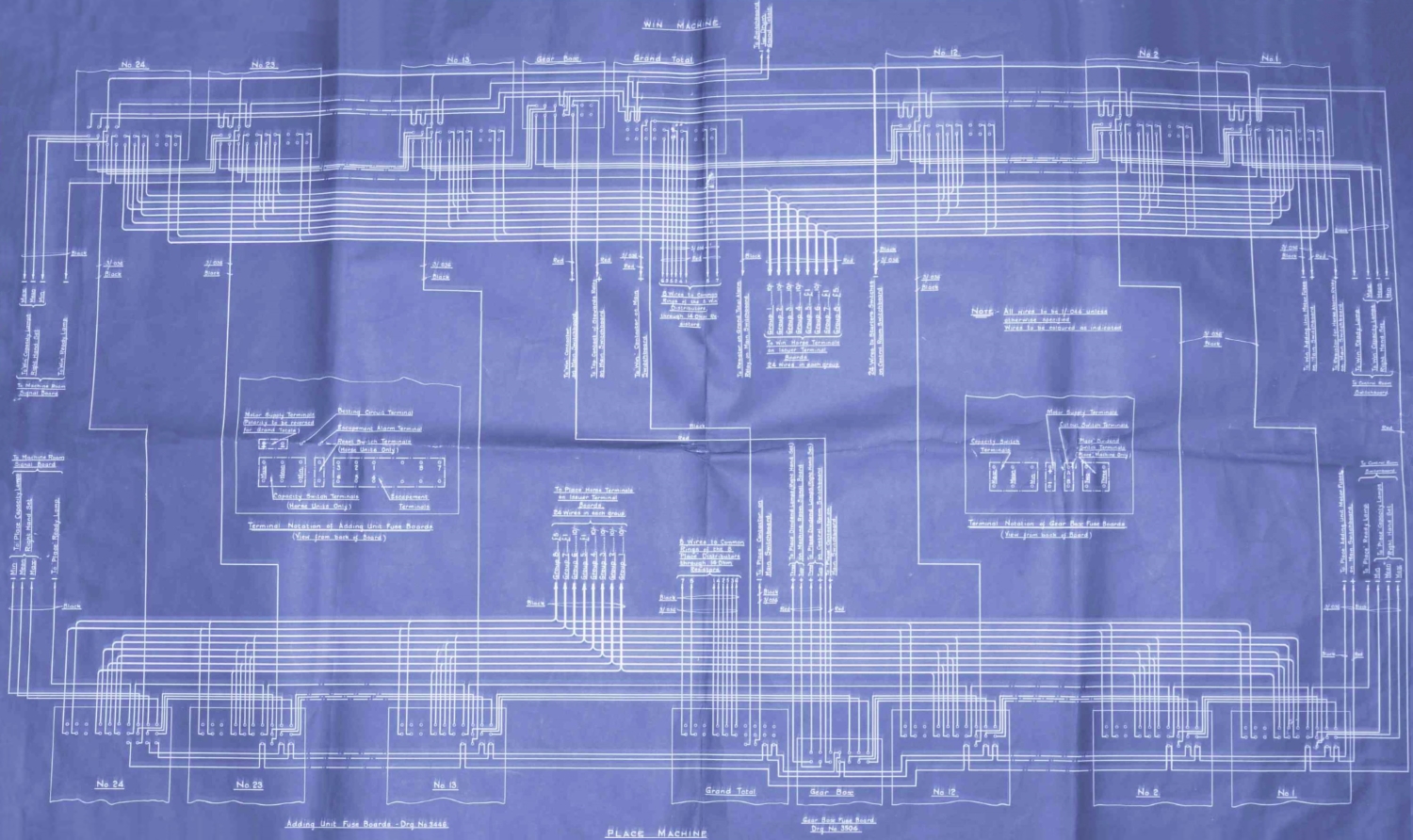

The image above is one of a collection of photographs of Julius Tote Blueprints that Bob sent me. It is a simplified interconnect diagram of a Julius Totalisator and the original drawing is titled WIRING TO ADDING UNIT FUSE BOARDS, not shown in the image above and bears the drawing designation that looks like 3500 - 713 however the lower part of 713 is obscured. Top centre of the image above are the words WIN MACHINE and bottom centre PLACE MACHINE. The drawing makes reference to two other drawings, the Adding Unit Fuse Boards Drg. No. 3446 bottom left and the Gear Box Fuse Board Drg. No. 3504 bottom to the right of the words PLACE MACHINE. I have not included these drawings in this page, however the Adding Unit Fuse Board is very similar to the Grand Total Fuse Board on the left hand side of the blueprint drawing several images below, titled Julius Poole and Gibson blueprint , and the Gear Box Fuse Board drawing is the same as the one shown in the bottom right quadrant of the same blueprint drawing below.

Every box in the drawing above, has a squiggly line either on the top or the bottom. I take this to be indicative of the fact that these boxes are not complete and are only representative of the equipment contained in them, which would be available if the part beyond the squiggly line was visible. Additionally every box in the drawing above contains a drawing representing an electrical connector or connectors. In all boxes except the ones labelled Gear Box the connectors are the same. They consist of two parallel rows of ten contacts or connection points each, with a third parallel row of four contacts, all of which look like little circles. I will refer to these contacts as pads, as this is what they are called on PCBs (Printed Circuit Boards.) Having mentioned PCBs, I must point out that the early Julius Totes pre-dated PCBs. These connectors are not the traditional connectors we think of in the electronics industry today. They are not self contained units arranged as plugs and sockets. They have connection points which I have called pads, which I suspect are solder joints. I will have a close look the next time I am near an old Julius Mainframe. In mainframe pictures of this Julius Tote era, these connection points are visible, without any detail, arranged exactly as seen in the drawing above, with two parallel rows of ten contacts and a third short parallel row of four contacts. The old text refers to these contacts/connection points as terminals. This can be confusing in the computer era as the TIMs (Ticket Issuing Machines), or in this old text what are called Issuers, can be thought of as terminals. The extra row of four contacts is flush with one end of the other two rows of contacts. It is interesting to note that the boxes seen in the row across the top of the drawing above, have been rotated around 180 degrees in the row across the bottom of the drawing. This is why the short row of four contacts move from being at the top left end of the connector in the top row boxes to the bottom right end of the connector in the bottom row boxes. This arrangement of connector is also seen in the blueprint drawing below titled Julius Poole and Gibson blueprint at the bottom of the box titled Grand Total Fuse Board on the left hand side of the drawing.

There are two boxes, which I call detail boxes, in the drawing above that are larger than any of the other boxes, one in the middle of the left hand half of the drawing and the other in the middle of the right hand half of the drawing. The left hand box has a label below it with Terminal Notation of Adding Unit Fuse Boards in the top line and View from back of Board below. The contents of this box shows the signal names for the conductors attached to all the connectors inside the Adding Unit Fuse Boards which are the ones titled No 1, No 2, No 12, No 13, No 23 and No 24. Although I have named these boxes detail boxes because they provide details about the use of each pertinent contact pad, it is obvious they do not provide any details of the component parts of the box which requires reference to additional detail drawings as seen in the blueprint drawing below.

A horizontal pair of contacts/pads in this Terminal Notation of Adding Unit Fuse Boards detail box, can be seen top left in the detail box, with a squat rectangle around them. This rectangle is labelled Motor Supply Terminals with the line (Polarity to be reversed below that, with for Grand Totals) in the third row. All three lines are underlined with the lowest underline extending to an arrow pointing back to the rectangle. Below the left pad is a + sign and below the right hand pad is a - sign. This is the direct current supply for the Adder's motor. To the right of the rectangle, is a single pad with a bent arrow pointing to it, which has the text Betting Circuit Terminal on the horizontal part of the arrow. The Betting Circuit is a rather complex circuit used to record tote transactions on the appropriate Adders. More on this later. To the right of that again, is another single pad with a bent arrow pointing to it, which has the text Escapement Alarm Terminal on the horizontal part of the arrow. The escapement alarm, signals the failure of the drive to an adding shaft in a particular adder. Below this Escapement Alarm Terminal line of text, there are another two separate lines, which read Reset Switch Terminals on top with the text (Horse Units Only) below, with an arrow on the left side of the text pointing down to the middle of three differently shaped rectangles. This middle rectangle is the thinnest of the three, containing two pads one on top of the other. The Reset Switches are a part of a signalling method described under the heading below 'RESET', 'READY' and 'ON' SIGNAL LAMP CIRCUITS./ Drawing NO. 3488. To the left of this middle rectangle is a wider rectangle containing three pairs of vertically separated pads arranged side by side, with an arrow pointing to it from below, with associated text reading Capacity Switch Terminals with a line below that reading (Horse Units Only). The three pairs of vertically separated pads have words between each pair of pads, that are rotated anticlockwise 90 degrees, so they sit vertical between the pairs of pads, that read Max between the first pair and Mean between the second pair and Min between the final pair in this rectangle. Max Mean and Min are capacity configurations for the expected turnover of a race used by the odds calculating system. Finally, to the right of the middle rectangle of three at the bottom of the Terminal Notation of Adding Unit Fuse Boards box, is the widest rectangle, containing six pairs of vertically separated pads sitting side by side, with an arrow pointing to the rectangle from below, with associated text reading Escapement above the word Terminals. The first three pairs of pads on the left hand side of this rectangle have numbers between each pair of pads with 3 below the first top pad, 2 below the second top pad 1 below the third top pad and similarly 6, 5, 4 above the first, second and third bottom pads respectively. Of the remaining three pairs of pads on the right hand side of this rectangle labelled Escapement Terminals, only two have associated numbers. They are the top right hand two labelled 8 on the left and 7 on the right. These pads are the means of connecting the electrical bus lines consisting of eight conductors, spanning most of the width along the top and the bottom of the blueprint drawing above.

The second of the two detail boxes previously mentioned, which is in the middle of the right hand half of the drawing above, has a label below it with Terminal Notation of Gear Box Fuse Boards in the top line and View from back of Board below. The contents of this box shows the signal names for the conductors attached to the connectors inside the two Gear Box Fuse Boards, one for the Win pool in the top row of units to the left of the Grand Total Unit labelled Gear Box and the other one for the Place pool in the bottom row of units to the right of the Grand Total Unit also labelled Gear Box. This detail box contains four rectangles in a row. The first rectangle on the left side of the box, is the same as the left hand one of three in a row in the previous detail box, containing three pairs of vertically separated pads arranged side by side with an arrow pointing to it from above, with associated text reading Capacity Switch above the word Terminals. To the right of this are two thin rectangles containing only two pads each, one on top of the other. The first rectangle has an angled arrow pointing to it from high above, with the words Motor Supply Terminals on top of the horizontal part of the arrow. The upper pad has a + sign underneath it the lower pad has a - sign above it. The second thin rectangle also has an angled arrow pointing to it from above with the words Cutout Switch Terminals on top of the horizontal part of the arrow, sitting below the Motor Supply Terminals label. The upper pad of this pair has an A below it and the lower pad has a B above it. This cut-out switch on the Gear Box unit is automatically opened if the Gear Box Unit fails to keep pace with the Grand Total Adding Unit. The final rectangle to the right is a box shape containing two pairs of vertically separated pads side by side. This box also has an angled arrow pointing to it from above. There are three lines of text above the horizontal part of this arrow which is close to the top of the box and reads Place Dividend on top and Switch Terminals below with (Place Machine Only) at the bottom. Both pairs of pads have vertically oriented words between each pair of pads, the left one reads "Two" and the right one reads "Three." The Julius Tote Place Pool Machine has to be configured for either a Two Place Dividend or a Three Place Dividend. More on this later.

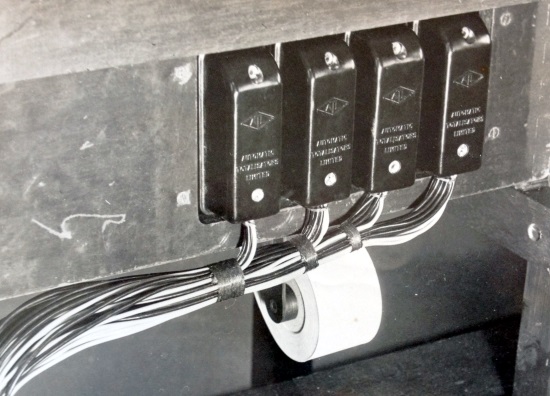

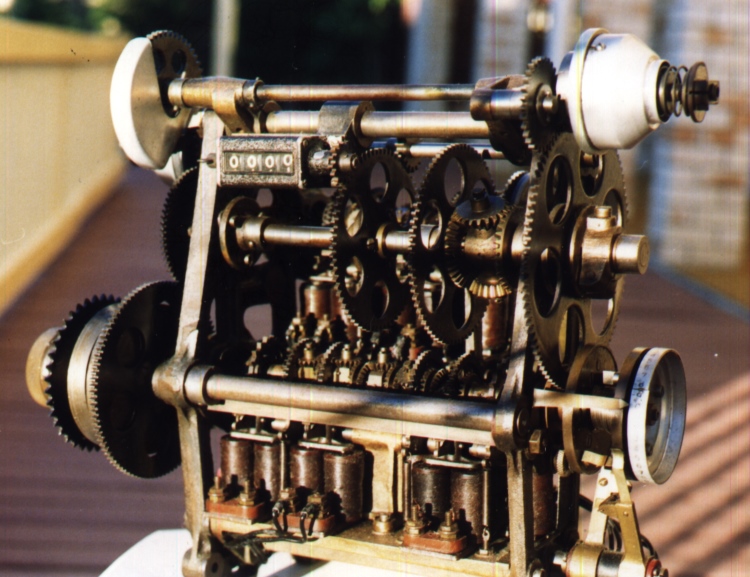

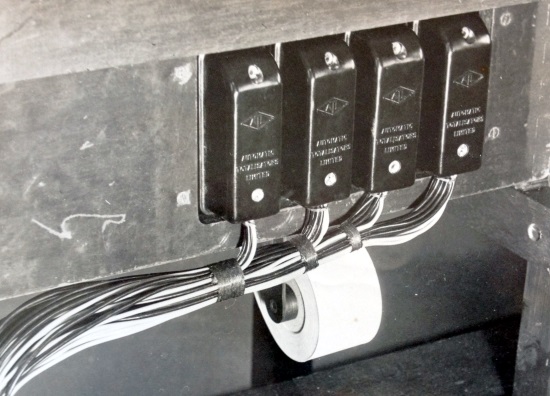

On the subject of connectors, during much of the Julius Tote era there was no well established electronics industry, so the plethora of connectors that became available when the electronics industry was well established, were not available and Automatic Totalisators Limited had to manufacture their own connectors. The image below shows four connectors that so far as I can tell were ubiquitous amongst Julius Totalisators. Even during my tenure with the company, which started in the late 1970s when I was working on a project utilising the the J22 terminals, these connectors were still in use. The J22 was the first microprocessor controlled TIM that Automatic Totalisators Limited developed and these J22 TIMs still had these connectors. This was probably for compatibility with existing installations to make upgrades easier. These connector plugs had two parallel rows of flat pins on them with eight pins in each row. Prior to the electronic/computer era these connectors were used to connect Julius Tote adders and TIMs to the rest of the electromechanical totalisator system.

Some Plastic Moulded ATL connectors

The ATL diamond logo can be seen embossed on each of the covers of these connectors in the image above, as well as the words Automatic on top of Totalisators on top of Limited below each diamond. I think the type of connectors shown in the blueprint drawing at the top of this page, arranged in two parallel rows of ten pads and a third short row or four, in the Adding Unit Fuse Boards and Grand Total Unit Fuse Boards, will have groups of wires attached to them creating leads, with a socket of the type shown in the image immediately above at the other end for each lead, for connection to the associated Grand Total Unit or Horse Adding Unit, which will be nearby. An example can be seen in the image below titled Image of part of the Harringay Julius Tote in Museum Storage. Six Adding Unit Fuse Boards can be seen with their white porcelain fuses along the bottom of the image, with their corresponding Horse Adding Units above them. Normally the plugs of the type shown above, in the image titled Some Plastic Moulded ATL connectors, connected to the TIMs and the Adders, and the cables emanating from the black plugs seen in the image above, probably come from TIMs. The sockets that the black plugs are plugged into, which look like they are permanently attached to a wooden cable tray, will have had cables connected to them inside the cable tray, that ran inside the cable tray to the Horse Units/Adders in the Machine Room with the scanners in the machine room providing the activation pulse for transaction cycles. Transaction cycles are performed by mechanical parts that interact with what is called the Betting Circuit as described in the company document text included below. These connections between the TIMs in the selling houses and the Horse Units in the machine room are described in the next paragraph. The roll of ticket paper seen sitting on a paper dispenser in the image above, confirms that the nearest TIM is not far away, probably on top of the bench vertically above. Below the ticket roll seems to be the floor level, the level at which the operator's feet will rest. Actually, I bet the odd operators foot has rested on the angled wooden support for the cable tray, seen at the right hand lower edge of the image above! An example of a TIM, the J7 is shown in the two images below titled The bottom of a J7 TIM (Issuer) Showing the Horse Halo and Top view of a J7 TIM (Issuer). The slot on the right hand side of the elevated section of the top of the J7 shown in the second mentioned image below, is where the tickets are ejected which requires the paper on the paper roll shown in the image above. The adder in the image below titled A Two Shaft Electro Mechanical Shaft Adder has one of these plugs mounted on the lower rear end of the left hand mounting plate, which is out of view of that image.

The electrical bus consisting of eight conductors, spanning most of the width along the top of the drawing at the top of this page, is attached to the Adding Unit Fuse Boards, labelled from right to left No 1, No 2, No 12, No 13, No 23 and No 24. These Adding Unit Fuse Boards are associated with the Adders which are part of the mainframe in the Machine Room. These eight bus signal conductors are shown exiting the drawing to the right of centre of the horizontal component of the bus where it descends vertically. These culminate in the drawing above, in a down bracket that points to the text To Win Horse Terminals followed by the line on Issuer Terminal followed by Boards and below that 24 Wires in each group. These Issuer Terminal Boards are associated with the TIMs that are in the Selling/Tote Houses. Above the down bracket the conductors are labelled according to the escapement wheel on the Adding Shafts (called Escapement Shafts in the old company document text presented later) in the Adding Units (called Horse Units in the old text) that they connect to. These labels are written vertically below the ends of the related conductors that are shown descending down the page, which terminate in downward pointing arrowheads pointing to the names. They read from left to right, Group 1 ----- 10/- followed by Group 2 ----- 10/- then Group 3 ----- 10/- then Group 4 ----- 10/- then Group 5 ----- 1£ then Group 6 ----- 10/- then Group 7 ----- 1£ and finally Group 8 ----- 5£. The values specified are determined by the number of teeth on the respective escapement wheels of the shaft adders. The more teeth the lesser value recorded as angular displacement on each activation. In the image below titled Julius Poole and Gibson blueprint a drawing of a Grand Total Unit, or what later was called a Grand Total Adder, can be seen to the left of centre in a tall rectangle with the label Grand Total Unit underneath it. I have been told that these Grand Total Units could be used as the Horse Units or Horse Adders, which summed the transactions for a particular runner. I have discovered there are some minor differences between them. If the Grand Total Unit in the blueprint drawing below were used as a Horse Unit, many of these adders would be plugged into the Adding Unit Fuse Boards, labelled from right to left No 1, No 2, No 12, No 13, No 23 and No 24 in the blueprint drawing at the top of this page, as well as all the other implied adder positions between 1 and 24 which are not included in the simplified representative examples, 1, 2, 12, 13, 23 and 24. These Fuse Boards are also shown in detail in the image below titled Julius Poole and Gibson blueprint inside the box on the left hand side with the label Grand Total Fuse Board below it. All this equipment is for the Win Pool and is repeated for the Place Pool as shown in the lower half of the Blueprint Drawing at the top of this page.

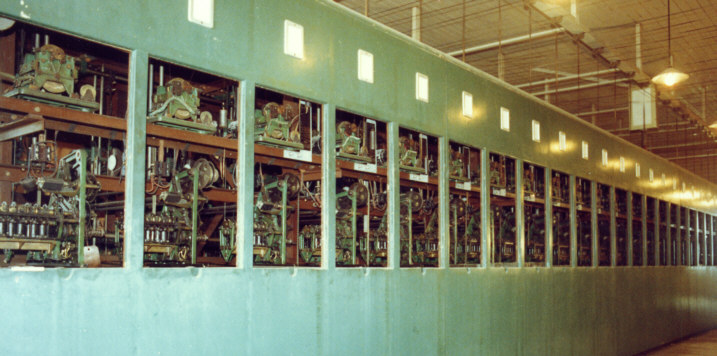

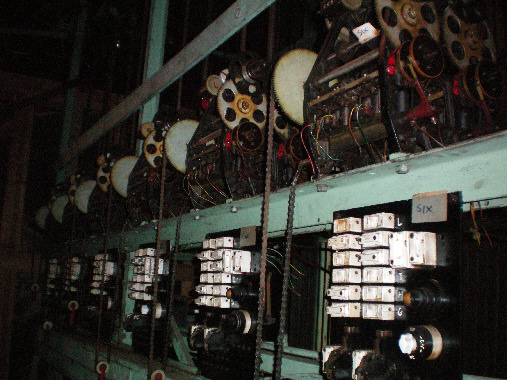

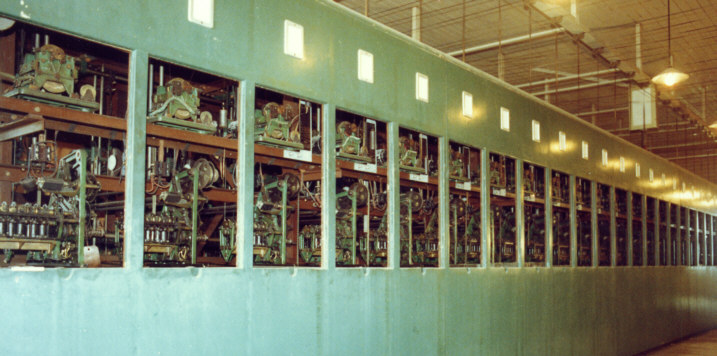

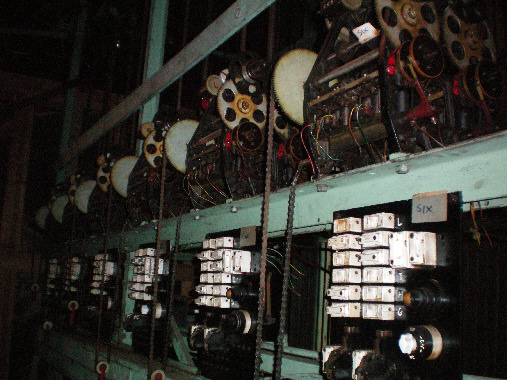

To emphasise what I have just written about the Horse Units and Grand Total Units, when looking at the two electrical buses spanning the width across the top and bottom of the image at the top of this page, keep in mind that this is only representative of a complete Julius Tote. The Julius Totes that I have seen, instead of having the representative six Horse Adders and a Grand Total Adder per pool, or what in the drawing are called Adding Units, they had twenty four Horse Adders plus a Grand Total Adder per pool. The image below shows part of the Place Pool processing equipment of a Julius Tote with the equipment in view repeated on the opposite side of the frame for the Win pool. Each window in the frame has a shaft adder like the one shown below in the image titled A Two Shaft Electro Mechanical Shaft Adder, although that adder is older than the ones in this image immediately below. Additionally there is display generating and driving equipment in each window, part of which is visible above each adder, with more associated equipment not visible in the image below obscured deeper inside the frame. The Adding Unit Fuse Boards mentioned in the previous paragraph are located inside the frame out of sight in the image below, one underneath every adder in each window. These Julius Totalisators were behemoth machines. The medium sized Julius Tote Mainframe in the image below is taller than I am. Let's have a quick look at the mass involved. The shaft adder in the image mentioned, titled A Two Shaft Electro Mechanical Shaft Adder weighs 26Kg. Each adder in the mainframe shown below will have a similar weight and there are 25 adders for the Place Pool on the near side of that mainframe and another 25 on the opposite side each weighing approximately 26Kg giving a total of 1,300Kg. The most highly produced Julius Tote TIM was the J8 and these were the most common TIM attached to the mainframe below and were distributed around the track. Assuming the different models of TIMs on this system weighed approximately the same as the J8, which is 34Kg, then fully populated with the maximum number of TIMs the mainframe below could support that is 128, the TIMs would weigh approximately 4,352 Kg giving a total of 5,652 Kg. This does not include the fuse boards that are associated with each adder, the odds calculating and indicator drive systems that are also associated with each adder, the gear boxes, the indicators, the heavy main drive electric motors for each pool along with the associated drive shafts and pulleys, the reciprocating engine driven generator and its standby generator set that produced the 120V DC supply and other ancillary equipment as well as the miles of cable. Having mentioned the miles of cable, Jack Bell in his Miami Herald article describing the Hialeah Julius tote, wrote that the amount of cable in that Julius Tote system was calculated to be 195 miles! Jack's Miami Herald article can be read in the Automatic Totalisators In America chapter of this website under the subheading Hialeah Park's Australian totalizator, by selecting the Go to the index button in the Navigation Bar at the bottom of this page and then selecting the quoted chapter in the Secondly part of the Index. I well remember being very impressed by the large lead encased power grade cables, running up a wall inside the old Main Tote House at Eagle Farm Racecourse, rising high from ground level disappearing into the very high ceiling in excess of two normal stories to enter the Julius Tote Machine Room on the first floor, that connected the TIMs in all the Tote Houses on the track to the Distributors/Scanners in the front end system in the machine room. Another significant weight that is not included is the Julius Tote front end system, which is out of sight in the image below standing along the right hand wall, includes three tall racks containing the Distributors/Scanners with ancillary equipment which had its own drive motors, part of which can be seen in the image below titled A small section of the Distributor and Relay Switchboard at White City London. Also not included, standing with the three Distributor racks mentioned, are two additional racks of equipment containing what is collectively described as the Main Switchboard in the machine room, in the old company document extract presented below under the heading CONTACTOR CONTROL CIRCUIT/ Drawing No. 3484. As what has not been included in my weight calculation is assuredly heavier than what has, I feel confident to ask the question have you ever heard of a calculator/computer that weighs over 10 Mega grams? Well they used to be prolific around the planet, however they were also clandestine, hidden in machine rooms and tote houses, so it is no surprise if you haven't heard of them, but now you are on the road to find out.

Part of a Julius Tote Mainframe.

The tall rectangle labelled Grand Total Unit to the right of the Grand Total Fuse Board rectangle in the image below titled Julius Poole and Gibson blueprint below, previously mentioned, is an electrical view of the Grand Total Unit or Adder. This electrical view of the Adder in the blueprint drawing below, shows the solenoids that trip the escapement mechanisms allowing the escapement wheels in the adding shafts (escapement shafts in the old text) to rotate and record bets. This is described in the third paragraph above the drawing below titled Julius Poole and Gibson blueprint. Everything relating to the electrical bus at the top of the blueprint drawing at the top of this page for the Win pool, also relates to the similar bus shown at the bottom of the drawing, except it relates to the Place pool and instead of the conductors shown descending to exit the drawing, they rise from the left of centre of the horizontal lower bus. Similarly, they culminate in the blueprint drawing above, in an up bracket that points to the text To Place Horse Terminals on Issuer Terminal Boards 24 Wires in each group only laid out as for the Win bus. These rising conductors are similarly labelled with vertical writing as before except instead of being ordered from left to right, they are ordered from right to left, and read from left to right: Group 8 ----- 5£ followed by Group 7 ----- 1£ then Group 6 ----- 10/- then Group 5 ----- 1£ then Group 4 ----- 10/- then Group 3 ----- 10/- then Group 2 ----- 10/- and finally Group 1 ----- 10/-. The lower bus related Adding Unit Fuse Boards are labelled as before, except they refer to Horse Units that are processing Place pool bets rather than Win pool bets.

I have included a transcription of the 1935 company document titled Automatic Totalisators Limited Description of Electrical Circuit Diagrams below. I have only provided two of the many blueprint images that Prof Bob Doran sent with this description document, as an example of what the Description of Electrical Circuit Diagrams document is describing. Generally, interconnect diagrams like the one at the top of this page provide a high level overview, with a multitude of other drawings providing details of what is contained in each of the different boxes in the interconnect diagram. As an example, as previously mentioned, the interconnect diagram shown at the top of this page makes mention of the Gear Box and a drawing Gear Box Fuse Board Drg. No. 3504. The blueprint drawing below titled Julius Poole and Gibson blueprint, has a number shown in the box at the bottom right corner which is 3503. I note that this blueprint drawing below contains two drawings the first on the left hand side bearing the labels Grand Total Fuse Board and Grand Total Unit, which is consistent with the name of this drawing shown at the bottom edge of the drawing Wiring To Grand Total Units. However, the second drawing on the right hand side bearing the labels Gear Box Fuse Board and Gear Box in the Blueprint drawing below is not mentioned in the title of the drawing and I suspect this is drawing number 3504. It is this drawing that provides the detail of the two boxes labelled Gear Box in the blueprint drawing at the top of this page. Similarly, the left hand drawing bearing the labels Grand Total Fuse Board and Grand Total Unit, of the two in the image below titled Julius Poole and Gibson blueprint, shows the detail of the two boxes labelled Grand Total in the blueprint drawing at the top of this page.

There is no drawing number on the image at the top of this page, however there are distinct similarities between it and drawing number 3509, to which the BETTING CIRCUIT description below, extracted from Automatic Totalisators Limited Description of Electrical Circuit Diagrams, applies. The Adding Unit Fuse Boards, mentioned in the first paragraph of the document extract below, are shown in the blueprint diagram at the top of this page in two rows numbered No 1, No 2, No 12, No 13, No 23 No 24, one across the top of the drawing for the Win Pool and the other across the bottom of the drawing for the Place Pool as described in the second paragraph above and one below, the image above titled Part of a Julius Tote Mainframe. Similarly the Issuer Terminal Boards, also mentioned in the first paragraph of the document extract below, are mentioned in the blueprint diagram at the top of this page in the text To Win Horse Terminals on Issuer Terminal Boards 24 Wires in each group, as well as, To Place Horse Terminals on Issuer Terminal Boards 24 Wires in each group, as identified in the two paragraphs already mentioned in the last sentence.

In the second paragraph of the BETTING CIRCUIT description below it mentions the diagram showing a Win and Place Machine which also applies to the blueprint diagram at the top of this page, the top half being the Win Machine and the bottom half the Place machine. Additionally in this paragraph below, it mentions The Grand Total Unit and three horse units are shown for each machine, which is more than covered by the blueprint drawing at the top of this page. The Grand Total Units are attached to Grand Total Unit Fuse Boards, and one of these Fuse Boards, which is for the Win pool, is represented by the box top centre in the blueprint drawing at the top of this page, below the heading WIN MACHINE with the label Grand Total above it. Another one of these Fuse Boards, which is for the Place pool, is represented by the box bottom centre in the blueprint drawing at the top of this page, above and to the right of the label PLACE MACHINE at the bottom edge of the drawing, with the label Grand Total inside the box. Regarding the three horse units are shown for each machine however, the blueprint drawing at the top of this page differs from drawing 3509 being described below, as it shows six horse units for each machine labelled No 1, No 2, No 12, No 13, No 23 and No 24, instead of three in drawing 3509. A second discrepancy in this second paragraph below the next heading, lies in the statement these units are shown with two escapement shafts and twelve escapements. Both the drawing above and the description below refer to Two Shaft Adders, or Units as referred to here, meaning they both have two escapement shafts, however the the ones in the drawing above have six escapements on one shaft and two on the second whilst the description below refers to Horse Adders/Horse Units with six escapements on both shafts. The fact that the drawing above relates to eight escapements and not twelve can be determined from the electrical bus cables grouped together under the labels To Win Horse Terminals on Issuer Terminal Boards 24 Wires in each group and To Place Horse Terminals on Issuer Terminal Boards 24 Wires in each group and individually identified as Group 1 through Group 8. Each of these eight Group Lines relates to an escapement wheel on every one of the respective Shaft Adders, or Horse Units as they are referred to in this text, in a specific installation. The use of the word Group in these escapement wheel bus lines relates to the fact that each escapement wheel in a shaft adder caters to a group of TIMs or Ticket Issuing Machines, which in the above drawing are called Issuer Terminals or just Issuers, which contain Issuer Terminal Boards as referred to in the drawing above in the text To Win Horse Terminals on Issuer Terminal Boards 24 Wires in each group. A group of TIMs were multiplexed by the Julius Tote Front End System containing devices called Distributors or in latter years Scanners. I have seen Distributors cater for up to sixteen TIMs on a single escapement. The number of TIMs/Issuers supported is dependent on the era that the Julius Tote was manufactured and the requirements of the specific system.

The third paragraph below the next heading mentions Three groups of Issuers and the corresponding Distributors and Relays that appear in Drawing No. 3509 and this level of detail is not shown in the Drawing at the top of this page. There is however, a reference to the Distributors in the blueprint drawing at the top of this page that reads 8 Wires to common Rings of the 8 Win Distributors through 14 Ohm Resistors. In the image below titled Julius Poole and Gibson blueprint a drawing of a Grand Total Unit, or what later was called a Grand Total Adder, can be seen to the left of centre in a tall rectangle with the label Grand Total Unit underneath it. If the Grand Total Unit in this blueprint drawing below were used as a Grand Total Unit as the name implies, and not as a Horse Unit, as previously suggested is possible, then two of the Grand Total Horse Units in the blueprint drawing below would be utilised. The first is used to calculate the Win Pool grand total and would be plugged into the Grand Total Unit Fuse Board, represented by the box top centre in the blueprint drawing at the top of this page, below the heading WIN MACHINE as mentioned in the previous paragraph. Eight conductors can be seen drawn descending from this Grand Total Unit Fuse Board culminating in a down bracket pointing to the previously mentioned text 8 Wires to common Rings of the 8 Win Distributors through 14 Ohm Resistors below. The second is used to calculate the Place Pool grand total and would be plugged into the Grand Total Unit Fuse Board, represented by the box bottom centre in the blueprint drawing at the top of this page, above and to the right of the label PLACE MACHINE at the bottom edge of the drawing which is also mentioned in the previous paragraph. Similar to the Win pool Grand Total Unit, there is a group of eight conductors rising from this Place pool Grand Total Unit box, from pads belonging to a connector represented inside the box, which terminate in an upward pointing bracket pointing to the text 8 Wires to common Rings of the 8 Place Distributors through 14 Ohm Resistors.

The sixth paragraph below the next heading mentions the Control Room Switchboard. There is an image of such a switch board at the bottom of this page. This switchboard was located at Hialeah racecourse, which is in Miami in the United States.

Following is the transcription of the company document titled Automatic Totalisators Limited Description of Electrical Circuit Diagrams:

BETTING CIRCUIT./ Drawing No. 3509.

This drawing shows the Betting Circuit in a diagrammatic form. To simplify the diagram the Issuer Terminal Boards and Adding Unit Fuse boards have been omitted although certain pieces of the equipment on the latter have been shown.

The diagram shows a Win and Place Machine. The Grand Total Unit and three horse units are shown for each machine and these units are shown with two escapement shafts and twelve escapements.

Three groups of issuers, each group containing two issuers are shown together with the corresponding Distributors and Relays.

A group of issuers may consist of any number of issuers up to a maximum of eight, all of which sell tickets of the same value and which are connected together to one escapement on the adding units. For convenience the issuers are usually numbered to correspond with the escapement to which they are connected, that is issuers connected to escapement No. 2 are numbered 21 to 28, issuers connected to Escapement no. 4 are numbered 41 to 48 and issuers connected to Escapement No. 12 are numbered 121 to 128 and so on.

The diagram my be extended to cover any number of horse units each of which may have any number of escapements and escapement shafts, the principle being identical in all cases.

On the Main Switchboard there is a Main Betting Circuit switch and fuses. From the - side of this switch a common feed is taken to the common side of a bank of 'Starters' switches on the Control Room Switchboard in the Manager's Office, there being one switch for each horse unit.

From the other side of each of these switches a lead is taken to the "Betting Circuit" switch on the corresponding Win and Place Horse Unit Fuse Boards.

The circuit through each horse unit is then as follows -. Through the Betting Circuit Switch and Fuse and through the normally closed contacts of the Escapement Cutout Relays (the operation and purpose of these relays is described elsewhere) to the common side of the escapement fuses, there being one fuse for each escapement and thence to the escapements.

From the escapements the circuit now proceeds to the corresponding contacts on the Horse Selector Segments of the corresponding issuers, that is the wire from No. 1 escapement on No. 1 Win Horse Unit is looped into the No. 1 Contact on the Win Horse Selector Segments of all issuers in No. 1 Group and so on.

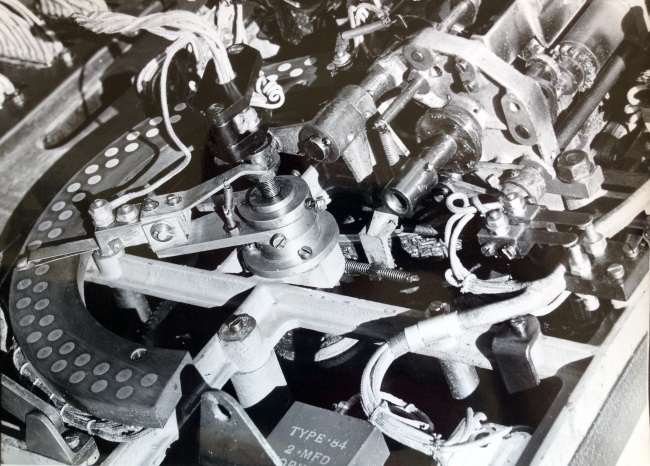

I have included the following image as an example of the 'Horse Selector Segments' mentioned above which in later years was called the Horse Halo. The arc seen with contact studs on it in the image below, was used to select the runner number required for the transaction. The TIMs (Ticket Issuing Machines) is what are called Issuers in the paragraph from the Description of Electrical Circuit Diagrams document above.

The bottom of a J7 TIM (Issuer) Showing the Horse Halo

Webmaster's notes

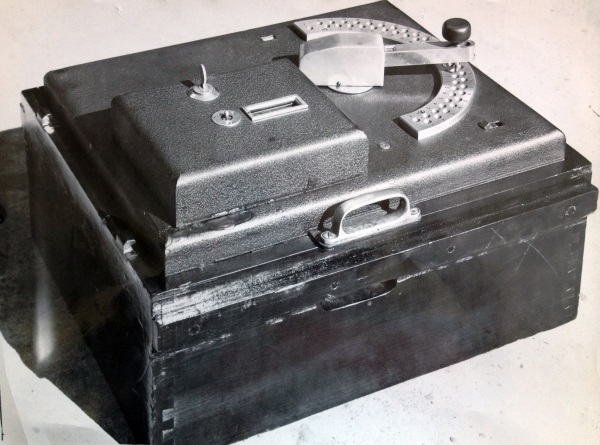

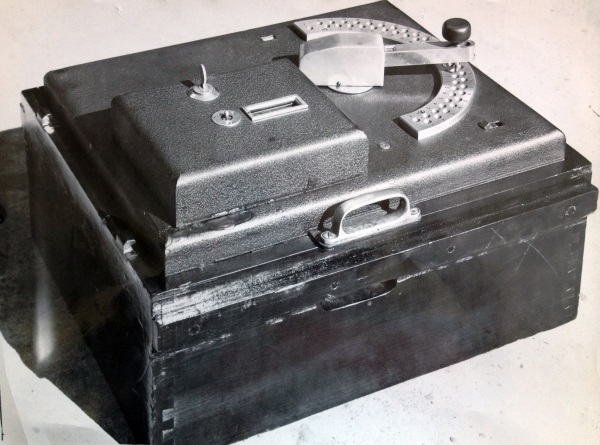

I have also included the image below to show what the top side of the J7 TIM looks like. The images above and below are not part of the Description of Electrical Circuit Diagrams document. These images show the business end of a totalisator system, where the totalisator tickets are sold. The largest Julius Totalisator I am aware of was installed in White City London commencing operation in 1933 which had 320 TIMs and the second largest was in Longchamps Paris commencing in 1928 with 273 terminals. The arm that sweeps across the arc, or Horse Halo, in the image above is connected to the runner selector handle seen on the top of the J7 on the right hand side in the image below.

The next paragraph in the continuation of the extract from the Description of Electrical Circuit Diagrams company document, which follows these notes, mentions the collecting brush which picks up the contacts on the Horse Selector Segments. The collecting brush can be seen in the image above about half way around the Horse Halo. The spindle the runner selection handle is anchored on in the image below, is at the centre of the runner selection semicircular plate with the runner locating holes in it and is the same spindle seen in the image above, which is a bottom view of the spindle. In the image above the end of the arm attached to this spindle has two metal strips attached, each extending to a position above their respective arc of contact pads. Each strip has a protruding electrical contact at its end, which makes contact with a selected contact pad on the associated arc of pads. These metal strips with the electrical contacts at their tips are the collecting brushes, one for each of the two arcs of contact pads. The outer arc of contact pads are for the Win Pool and the inner arc of contacts are for the Place Pool and these pads correspond with the locating holes in the runner selection semicircular plate on the top of the J7 shown in the image below. The Win or Place pool is selected by the knob on top of the runner selection arm in the image below, depending on whether the knob is pushed longitudinally along the arm to its outer or inner limit. Usually, there are as many studs in each arc as the maximum possible number of runners in a race plus one for printing test tickets.

The HANDLE LOCK SWITCH ON ISSUER, is the title of item 7 in the list of 14 items below, extracted from the company document titled Description of Electrical Circuit Diagrams. The HANDLE LOCK mechanism can be seen in the image below. It involves the knob on top of and at the right hand end of the runner selector arm, which when pressed pushes a pin into a locating hole to lock the handle on the selected runner and pool closing the HANDLE LOCK SWITCH, to stop the knob moving once a selection is made. This holds the brush on top of the contact in the horse halo shown in the image above and keeps the contacts in place for the duration of the transaction cycle at the end of which the HANDLE LOCK SWITCH is opened and the knob pops back out restoring the pool selection knob and runner selection arm movement. The knob on the top of the runner selection handle can be moved a short distance radially along the runner selection arm. In the outer position it selects the Win Pool and in the inner position it selects the Place Pool. The slot in which the knob moves radially along the arm can be seen in the image below to the right of the knob.

The ISSUER TRIP COIL AND TRIP SWITCH is the title of item 8 in the list of 14 items below, extracted from the company document. There is a switch near the right hand edge of the image above at about mid height level. At or just below mid height level, touching the right hand edge of the image above, is the corner of what looks like a square black Lego piece. Being black it contrasts with the bright coloured frame of the J7 to which it is attached. The demarcation line between the two can be seen descending to the left from the right hand edge of the image above, just below mid height level, black on top bright grey almost white below. Like a Lego piece, the black piece in the image above is probably an insulator as it holds electrical connections. Instead of the four raised cylindrical connector sections on top of a Lego piece, there are four screws in similar positions instead. The two pan heads of the right hand pair of screws can be seen flush with the surface of what I will call the square insulator instead of relating it to a Lego piece. These screws secure the square insulator to the frame. The threaded section of the two left hand screws can be seen rising above the square insulator and nuts can be seen on the threaded shaft section of the screws, which are in contact with the square insulator securing the screws to the insulator. Above the top of these two screws are the tips of two metal strips, which are not in contact with the screws below, extending from two separate anchor points at the left hand ends of the strips. These anchor points are on top of a similar looking square insulator, except that there are only two screws on the top surface, each passing through its own rectangular metal strip with a nut on each screw clamping the respective rectangular strips and their protruding metal strips underneath, to the square insulator. On top of each of these nuts on each screw are a pair of washers with another nut on top of each pair of washers clamping the washers together. A conductor is clamped between each of the pairs of washers. The outer insulation of these conductors can be seen on the left hand side of each of the pairs of nuts on each screw. This left hand upper square insulator is capable of being rotated clockwise, such that after rotating, the protruding metal strips make contact with their respective screw shafts beneath them and this action is the closing of a two pole single throw switch. I think this is the TRIP SWITCH mentioned in item 8 of the list. From another image I have not included, taken from a perspective top right hand corner of the image above looking back at the Trip Switch, the pivot for this rotation of the top contacts of the switch can be seen. Additionally in this other perspective, an activating rod for this rotation can be seen attached to a plate, which is attached to the side of the square insulator, on the opposite side to the side visible in the image above. Below the first described square insulator, which is at the right hand edge of the image above, is a coil behind the downward extension of the bottom left screw, which can be seen extending below this insulator. It is not possible to clearly see this coil at the resolution and size of the image above however it can just be made out by enlarging the above image. It is very clear in a high resolution version of this image. I think this coil is part of the solenoid mentioned in item 8, the plunger of which is probably attached to the activating rod just mentioned that controls the Trip Switch. Additionally in the image not included here showing the different perspective, a large coil can be seen, which is located off the right hand side of the image above close to the top of the image. A shadow can be seen on the side of the motor near the top right corner of the image above and this I think is cast by this large coil and I think this is the Trip Coil mentioned in item 8.

The ISSUER SWITCH ON ISSUER, is the title of item 9 in the list of 14 items below, extracted from the company document. There are two switches seen on the top of the J7 shown in the image below. I think the switch that cuts out the issuer as mentioned in item 9, is the switch at the bottom right hand corner of the J7 in the image below. There is however, a second switch on the J7 that can be seen on the raised section of the top of the machine, to the left of the ticket issue slot. The key seen behind this second switch is probably the key that locks the lid of the machine down so that removing the top cover of the machine can be restricted to technical staff only, which were called mechanics or engineers at the time of the Julius Totalisators or technicians or engineers in the electronic/computer era.

Following is the continuation of the transcription of Automatic Totalisators Limited Description of Electrical Circuit Diagrams:

Top view of a J7 TIM (Issuer)

The circuit through each Issuer is then as follows. From the collecting brush which picks up the contacts on the Horse Selector Segments through the Handle Lock Switch (closed only when the handle is locked down) through the Trip Coil, through the trip switch (normally closed when the Issuer is stationary), through the Issuer Switch (Tumbler Switch on Issuer Cover Plate) to the Win - Place Selector Switch.

From each Issuer two wires (one for Win and one for Place) are taken from the Contacts of the Win-Place Selector Switch to the Double Pole Issuer Common Switches on the bottom of the Distributor and Relay Switchboard and thence through the coils of the corresponding Relays to the Distributor Contacts. There are a pair of relays (one Win and one Place) for each Issuer and a pair of Distributors (one Win and one Place) for each Group of Issuers and each Distributor has 8 contacts corresponding to the 8 issuers in the group.

From the Common ring of each distributor, leads are taken to the corresponding escapement magnets on the two Grand Total Units.

The circuit through the Grand Total Units is as follows. Through Escapement magnet and corresponding escapement fuse, through contacts of Escapement Cutout Relay and through Betting Circuit Fuse and Switch.

From the Betting Circuit Switch of each Grand Total Fuse Board a lead is taken to the contacts of the Win and Place Contactors on the Main Switchboard and thence through those contacts to the + side of the Main Betting Circuit Switch and Fuse.

Webmaster's notes:

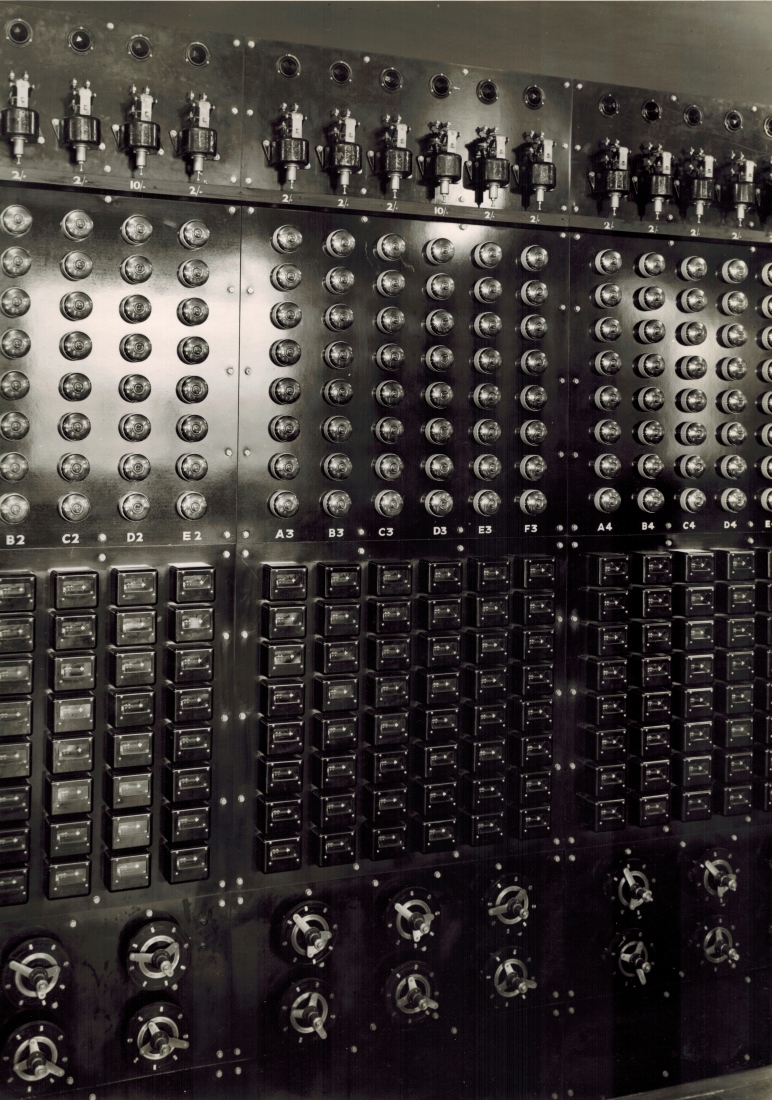

In the second paragraph below the image above, it mentions Issuer Common Switches on the bottom of the Distributor and Relay Switchboard. These Switches Distributors and Relays can be seen in the image below, although the White City Distributor and Relay Switchboard seen in that image, was laid out a little differently to the one being described in the old company document extract above. The Issuer Common Switches are not at the bottom of the distributor switchboard panels shown below, the distributors are at the bottom instead. The equipment shown in the image below is arranged into repeated columns and in that image only the centre column is completely in view. Across the top of the image below are a row of cut out relays or what today would be called circuit breakers and there are six of them in the central column. Below this in the central column, is a matrix of switches six across and eight down and these are the Issuer Common Switches.

The Grand Total Fuse Board, mentioned in the last paragraph before these notes, can be seen in the tall oblong rectangle, with an underlined label below it of the same name, next to the left hand side of the blueprint drawing below titled Julius Poole and Gibson blueprint. The third paragraph below the image above, relating to the Betting Circuit, mentions leads are taken to the corresponding escapement magnets on the two Grand Total Units. This connection marks the beginning of the path through the Grand Total Fuse Boards and the Grand Total Units, which can be traced through the drawing on the left hand side of the Julius Poole and Gibson blueprint below. I have chosen to trace the path relating to escapement number 7 in the Grand Total Unit, as it is easier to describe that path through the drawings. One of the leads mentioned which corresponds with escapement number 7, enters the Grand Total Fuse Board shown in the tall rectangle nearest the left hand edge of the Julius Poole and Gibson blueprint below, via a connector shown at the bottom of this rectangle with the underlined label text Escapement Terminals below it at the very bottom of the rectangle, which is hard to read without enlarging the image. The obvious part of this connector appears as two rows of ten small circles one on top of the other, across the bottom of the rectangle. These small circles represent electrical connections between the external wiring and the internal wiring of the Grand Total Fuse Board. The right hand small circle of ten in the top row, has the number 7 below it indicating it belongs to escapement number 7. The connection then travels right in the drawing and exits the Grand Total Fuse Board rectangle and then rises to a position higher than the top of the Grand Total Fuse Board rectangle where it turns right to enter the second rectangle in this drawing. This second rectangle is taller than the first, in this drawing on the left hand side of the Julius Poole and Gibson blueprint below and is labelled Grand Total Unit below the rectangle. From here the conductor continues right near the top of the Grand Total Unit rectangle to about half way across it and then descends a short distance to join the right hand coil of two, which constitute the number 7 escapement electromagnet, represented as two medium sized circles in the blueprint drawing below. The fourth paragraph below the image above starts with The circuit through the Grand Total Units is as follows. Through Escapement magnet and ... We have just arrived in this example at the Escapement magnet mentioned in the company document extract above. Following the circuit in the Blueprint Drawing below, the two coils are shown electrically connected together by a wire joining the bottom of the two circles representing the coils. It is through this wire that we manage to pass Through Escapement magnet as mentioned in the fourth paragraph below the image above. The circuit continues up out of the left hand coil and turns left immediately below the top of the Grand Total Unit rectangle, continuing left across the top and exiting the rectangle on the left hand side, then descending before turning left again to re-enter the Grand Total Fuse Board rectangle in the top right quadrant. Here it continues left a short distance and then descends to join the left hand side of a fuse labelled 7-£1, specifying this as the fuse for escapement 7, which registers £1 bets for every activation of the associated escapement wheel, which is advanced a tooth by the electromagnet the Betting Circuit has just been through, by activating its associated escapement mechanism. There is a label in the blueprint drawing below, above this fuse that reads: Escapement Fuses. We have now reached the point in the circuit description text in the fourth paragraph below the image above, that states ... and corresponding escapement fuse. The Betting Circuit continues through the fuse and then from the right hand end of the fuse downwards, passing through a small connection circle with another fuse, continuing downwards then turns left for a short distance and joins another small circle indicating a connection with a switch. Here the betting circuit does not descend further with the continuous line but travels from the small connection circle down the arm of the switch represented by a descending broken line leaning slightly left of vertical. We have just passed through the Escapement Cutout Relay mentioned in the fourth paragraph below the image above. In the blueprint drawing below this is labelled Alarm Relay, which is difficult to read. It is called the Alarm Relay as an Escapement Cutout raises an alarm. In other words, both names refer to the same relay. This broken line switch arm belonging to this relay now joins another connection circle in the blueprint drawing below, which is also the switch arm pivot point, where the Betting Circuit leaves the switch heading right a short distance then up before turning left a short distance, descends and turns left again to meet a connection with another arm of a similar switch. The circuit continues left past the connector, not entering this second switch, rises, turns left, rises again and turns left then rises again a final time and turns left joining the top of another fuse. This is the Betting Circuit Fuse mentioned near the end of the fourth paragraph beneath the image above. The Betting Circuit passes down through this fuse continues down then turns right and down again a short distance and joins another connection circle. This has a horizontal broken line joining another connection circle to the left of the first. This broken line represents the Betting Circuit Switch and has the label Betting Circuit Switch below it and is the end of the description in the fourth paragraph below the image above, which reads ... and through Betting Circuit Fuse and Switch. From the left hand end of the switch the betting circuit continues downwards joining another connection circle which is part of the original connector we started with. This connector was described at the beginning of this paragraph as the obvious part of this connector appears as two rows of ten small circles. There is another, not so obvious, row of four small circles above the two rows described. It is the third connection circle in this upper short row of the connector that the Betting Circuit exits the Grand Total Fuse Board on, which is identified in the Blueprint drawing below with the words Betting Circuit on top of the word Terminal and an arrow pointing down to the right from this word to the identified connector terminal in this connector. As stated in the last paragraph before these notes, from this connector contact, which is attached to the Betting Circuit Switch the betting circuit extends further through the following means: a lead is taken to the contacts of the Win and Place Contactors on the Main Switchboard.

Item 3 in the list below, is the BETTING CIRCUIT SWITCH ON HORSE UNIT FUSE BOARDS. The Horse Units are almost the same as the Grand Total Units, and the Betting Circuit Switch mentioned in my last paragraph above relating to the Grand Total Fuse Board is the same as the one in the Horse Unit Fuse Boards mentioned below. N.B. The name Horse Unit in these old documents is synonymous with the name Adding Unit.

Following is the continuation of the transcription of Automatic Totalisators Limited Description of Electrical Circuit Diagrams:

The function and operation of the various switches, relays etc. in the circuit are as follows.

- MAIN BETTING CIRCUIT SWITCH AND FUSES ON MAIN SWITCHBOARD.

This switch controls the whole of the betting circuits on both poles. This switch is closed at the beginning of the day and is kept closed during the whole of the day.

- STARTERS SWITCHES ON CONTROL ROOM SWITCHBOARD.

These switches control the negative supply to each horse unit and enable the Manager to cutout all units except those for the actual 'Starters' in the Race. This prevents tickets being sold on Scratched horses. These switches are operated by the Manager before each race.

- BETTING CIRCUIT SWITCH ON HORSE UNIT FUSE BOARDS.

This switch controls the negative supply to the corresponding horse unit and enables the Mechanic to cutout a Horse Unit if any trouble occurs and so prevent further betting on that Horse until the trouble has been fixed. These switches are left closed for the whole of the day.

- ESCAPEMENT CUTOUT RELAYS ON ADDING UNIT FUSE BOARDS.

These relays automatically trip and interrupt the Betting Circuit if the driving gear to the adding unit fails. The operation of these Relays is described elsewhere.

- ESCAPEMENT MAGNETS ON HORSE UNITS.

These magnets operate the adding escapements which record each bet on the appropriate horse and Grand Total Unit.

- HORSE SELECTOR SEGMENT ON ISSUER.

These selector segments operate with a moving contact arm which is controlled by the Selector Handle of the Issuer and so connect the Issuer to the Horse Unit corresponding to the Horse for which the Ticket is to be issued.

- HANDLE LOCK SWITCH ON ISSUER.

This switch is only closed when the Selector Handle has been pressed and locked into the hole on the Selector Plate corresponding to the Horse for which the ticket is to be issued. This switch remains closed and the handle is locked down until the cycle of the Issuer has been practically completed.

- ISSUER TRIP COIL AND TRIP SWITCH.

This Trip Coil is in series with the escapement magnets. When the Betting Circuit is completed the appropriate Horse and Grand Total Escapement Magnets and the Issuer Trip Coil are all energised at the one time. The Trip Coil operates a solenoid plunger which at the end of its stroke, opens the Issuer Trip Switch and so interrupts the Betting Circuit and at the same time the plunger releases a mechanical latch on the Issuer and closes the circuit for the magnetic clutch and the Issuer then prints and issues the ticket.

The trip coil plunger is arranged so that it is slower in operation than the escapement magnets so as to ensure that the trip switch is not opened before the escapement magnets have operated.

- ISSUER SWITCH ON ISSUER.

This is a tumbler switch on the Issuer Cover and enables the Seller to cutout the issuer when she leaves it unattended.

- WIN-PLACE SELECTOR SWITCH ON ISSUER.

This switch is operated by the Issuer Selector Handle and serves to connect the Issuer to either the Win or Place Adding units as required.

- ISSUER COMMON SWITCHES ON DISTRIBUTOR SWITCHBOARD.

There is one of these switches for each Issuer and they enable any issuer to be cut out from the Machine Room when it is not in use and so prevent the unauthorised use of the issuers.

- DISTRIBUTORS.

There are a pair of Distributors for each Group of Issuers, that is for each Escapement, one for Win and one for Place. Each distributor has 8 contact studs and a common contact ring and a contact arm is continually rotated thus connecting the ring to each stud in turn. The distributors are driven at a speed of about 90 revolutions per minute by means of a motor and suitable gearing.

The eight studs are connected to the 8 issuers in the group and the common ring is connected to the corresponding Grand Total Escapement, so that the distributor serves to connect the 8 issuers in the group to the one escapement magnet in turn, that is the circuit is only completed through one issuer at a time even if the whole 8 issuers have their handles depressed at the same instant. This enables one escapement to record the bets from 8 issuers.

When an issuer handle is depressed, the Betting Circuit is not completed until the Distributor Contact arm reaches the stud corresponding to that issuer. The Issuer Trip Coil plunger is arranged so that it will operate and so open the Betting Circuit again before the Distributor reaches the next Contact stud, thus enabling the escapement to make its return stroke and be ready to record the bet from the next issuer in the group if its handle has been depressed.

- RELAYS ON DISTRIBUTOR BOARD.

There are a pair of relays, one for Win and one for Place for each Issuer.

These relays serve to provide a definite time for the Issuer Trip Coil to function even if the Issuer Handle is depressed just as the Distributor Contact arm is leaving the Contact Stud corresponding to that Issuer.

The relay coil is connected in series with the Trip Coil and escapement magnets and so is energised when the Betting circuit is completed. The relay contacts are arranged so as to short circuit the distributor when the relay closes. Thus the Betting Circuit is maintained when the Distributor Contact arm leaves the contact stud and is only broken by the Issuer Trip Switch. The relay is very quick in operation and will close and so maintain the circuit if the Issuer Handle is depressed just as the Distributor Contact arm is leaving the contact stud.

- WIN AND PLACE CONTACTORS ON MAIN SWITCHBOARD.

These Contactors control the positive supply to the two Grand Total units and thus no betting can occur when they are open.

They are magnetically operated and only close when the Managers and Mechanics Control Switches are closed. They are also automatically opened by the operation of the Stewards switch. The circuit controlling these Contactors is described elsewhere.

Webmaster's notes:

In item 2 in the list above the Starters Switches, which control the negative supply to each horse unit are mentioned. These negative supply conductors are shown in the drawing at the top of this page. They are easy to locate as they are represented by the highest horizontal line spanning most of the width of the drawing running across the top of the top row of boxes. These conductors can be seen exiting the drawing represented by a vertical line, an extension of the horizontal line, passing down the left hand side of the top row box labelled No 12. This has two lines of text, rotated anticlockwise 90 degrees to orient them vertically, at the bottom of the vertical line that reads 24 Wires to Starters Switches on the left and on Control Room Switchboard to the right. The horizontal component of these lines can be seen passing through the Gear Box and Grand Total boxes, amongst the top row of boxes, without any connection. However, there are connections in each of the sample Horse Units labelled No 13, No 23 and No 24 to the left of the vertical component of the line representing these conductors and No 1, No 2 and No 12 to the right. As the highest Horse Unit number in the drawing at the top of this page is 24, amongst the six sample Horse Unit numbers shown for the Win Pool in the drawing, we can deduce that this is the highest Horse Unit number. Additionally, 24 was a common maximum field size for races, certainly in my time, although much higher field sizes were prevalent in the earlier Julius Totalisators. This maximum field size of 24 is consistent with the labelling for these conductors in the drawing above, the first line of text reading 24 Wires to Starters Switches, which is one for each of the Horse Units.

As item 2 in the list above refers to scratchings, which I will add includes runners in excess of the highest numbered horse in a race, it is clear that if a horse is a non runner, then there should be no sales on either the Win pool or the Place pool on these runners. This can be seen facilitated in the drawing at the top of this page. For every connection of these conductors from the Starters Switches, that connect to a terminal in each of the Win pool Horse Units, the connection is shown for each Win pool Horse Unit, extending further down the drawing to a similar connection in the counterpart Horse Unit belonging to the group of Place pool Horse Units. These Place pool Horse Units are represented by the boxes labelled No 1, No 2, No 12, No 13, No 23 and No 24 from right to left across the bottom of the drawing above. In other words for any of the 24 starters switches that are left open, the Win pool and Place pool corresponding adders for that runner will be disabled.

Item 4 in the list above is titled ESCAPEMENT CUTOUT RELAYS ON ADDING UNIT FUSE BOARDS. As these boards are almost identical to the Grand Total Fuse Board the Escapement Cutout Relay mentioned can be seen in the blueprint drawing below, only it is labelled Alarm Relay as described in the paragraph above the blueprint drawing below titled Julius Poole and Gibson blueprint.

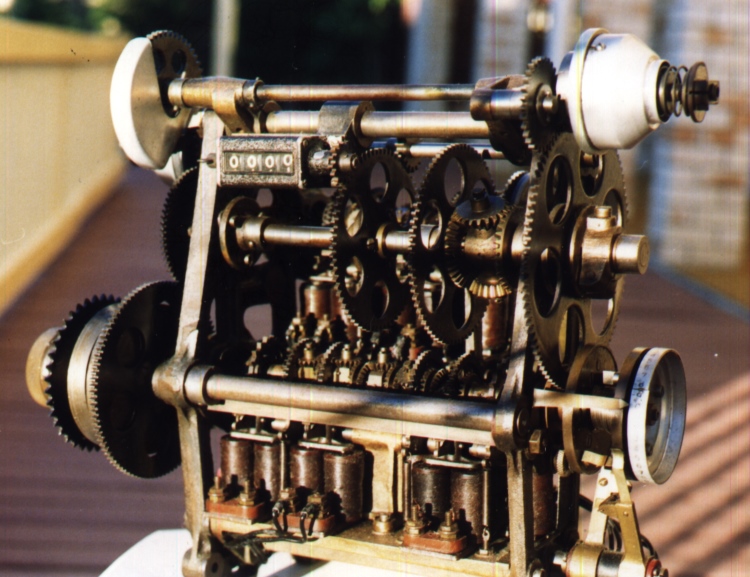

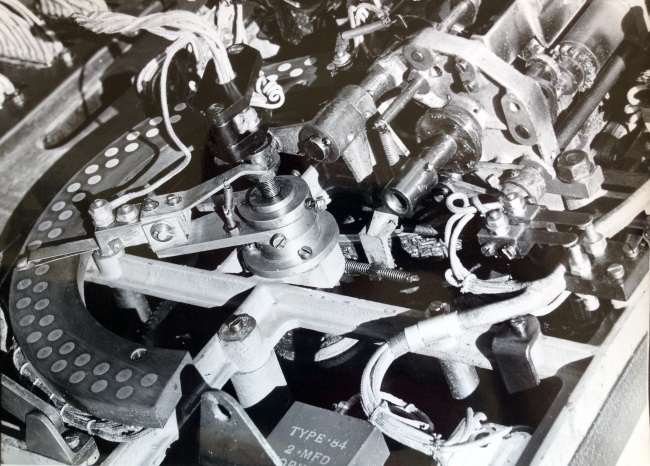

Item 5 in the list above is titled ESCAPEMENT MAGNETS ON HORSE UNITS. These Escapement Magnets mentioned, which are electromagnets, are part of what today is called a solenoid. the escapement trip mechanisms are activated by solenoids as a result of pulses from the TIMs sequenced by the Distributors. These Escapement Magnets/solenoids, are described in the third paragraph above the image below titled Julius Poole and Gibson blueprint.

Item 12 in the list above is titled DISTRIBUTORS. I have included the image below that shows these distributors:

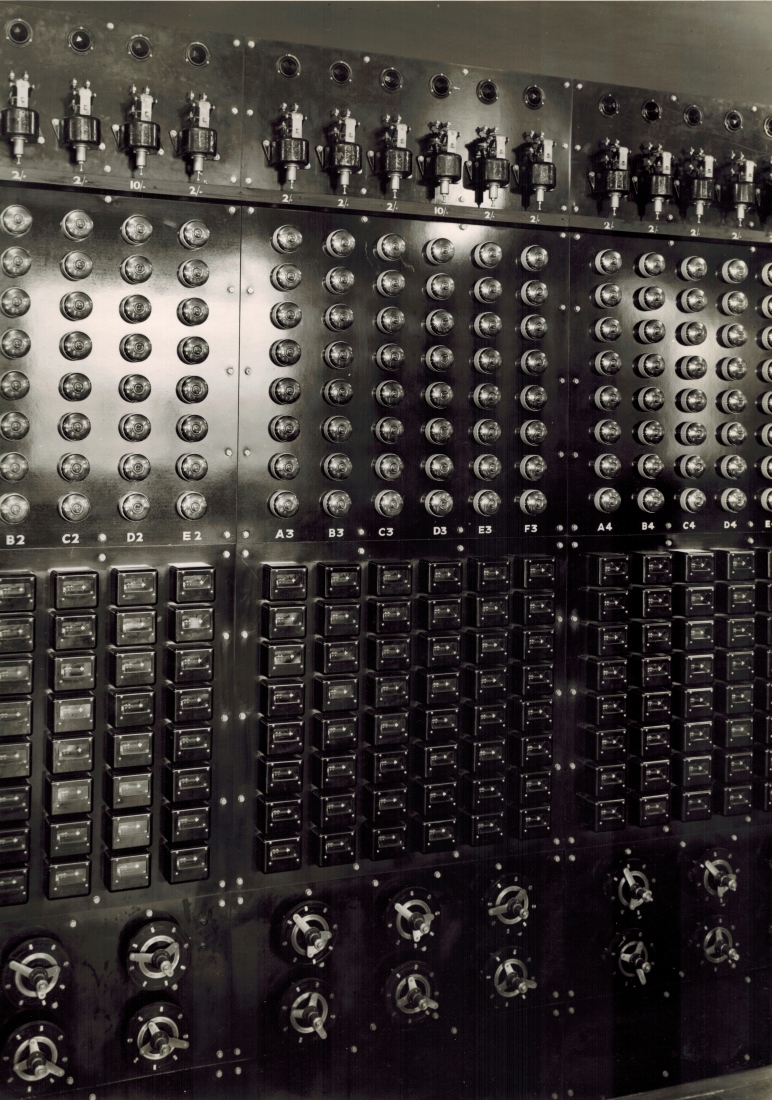

A small section of the Distributor and Relay Switchboard at White City London

In item 12 of the list above, the first sentence reads: There are a pair of Distributors for each Group of Issuers, that is for each Escapement, one for Win and one for Place. The image above only shows a small section of the Distributor and Relay Switchboard, so that the detail can be seen. To see the complete Switchboard, click on the image at the top of this page, scroll up to the heading in the Photo Gallery index starting with White City Stadium London 1933 - then scroll down and select the thumbnail with the associated text starting The main switch board.... Back to the image above, these Distributors are the circular devices at the bottom of that image, one row for the Win Pool and the other row for the Place Pool. Item 12 also states Each distributor has 8 contact studs and a common contact ring and a contact arm. The common contact ring is the continuous ring around the centre of the scanner and the 8 contact studs can be seen arranged in a circle around the continuous ring. The contact arm is a little different in the image above. In many installations, like the one being described, there is a single long contact arm spanning the diameter of the outer ring of the distributor, rotating about its centre. However in the image above there are three contact arms, pivoted at the central hub and radiating out separated from each other by 120 degrees. Two of the arms are shorter than the third and are in contact with the inner ring as the arm assembly rotates. These arms have surfaces that make electrical contact with the continuous ring. The third arm is longer and it makes electrical connections with the individual studs in the broken ring as this arm passes over them effectively connecting the continuous ring to the stud as the arm passes over them.

Item 13 in the list above is titled RELAYS ON DISTRIBUTOR BOARD. The first sentence reads: There are a pair of relays, one for Win and one for Place for each Issuer. The relays are seen in banks of equipment above each group of distributors. Looking at the centre bank of six distributors, three in the top row and three underneath, there is a matrix of six across by eight down relays, located directly above the six distributors. Each column of eight relays provides one relay per stud on the column associated distributor and the six columns of relays are one for each distributor in the group of six.

Item 14 in the list above is titled WIN AND PLACE CONTACTORS ON MAIN SWITCHBOARD. The wires from these contactors can be seen in the drawing at the top of this page. In the Grand Total box in the middle of the top row of boxes, attached to the third pad from the left in the top row of four pads in the connector shown at the bottom of this box, there is a conductor seen descending through the bottom of the box and crossing the horizontal bus of eight conductors and terminating in a + sign. Below this sign there is the vertically oriented text associated with this conductor, which reads To Win Contactor on Main on the left with Switchboard on the right. Similarly, in the Grand Total box near the middle of the bottom row of boxes, attached to the third pad from the right in the bottom row of pads, in the connector shown at the top of this box, there is a conductor seen rising through the top of the box and crossing the horizontal bus of eight conductors and terminating in a - sign. Above this sign there is the vertically oriented text associated with this conductor which reads To Place Contactor on on the left with Main Switchboard on the right. These are the two wires that implement the statement These Contactors control the positive supply to the two Grand Total units ... in item 14 in the list above. Another such connection to these contactors can be seen in the Gear Box box in the top row of boxes, attached to the third pad from the right in the bottom row of pads, in the connector shown in this box. There is a conductor seen descending through the bottom of the box and crossing the horizontal bus of eight conductors and terminating in a + sign. Below this sign there is the vertically oriented text associated with this conductor which reads To Win Contactor on the left with on Main Switchboard on the right. Similarly, in the Gear Box box in the bottom row of boxes, attached to the third pad from the left in the top row of pads of the connector shown at the top of this box, there is a conductor seen rising through the top of the box and crossing the horizontal bus of eight conductors and terminating in a + sign. Above this sign there is the vertically oriented text associated with this conductor which reads To Place Contactor on on the left with Main Switchboard on the right.

Following is the continuation of the transcription of Automatic Totalisators Limited Description of Electrical Circuit Diagrams:

To illustrate the operation of the Betting Circuit more clearly, assume that No. 22 Issuer is to Issue a 'Win' Ticket on No. 3 horse. The circuit will then be as follows-

- From - pole of Main Betting Circuit Switch on Main Switchboard to common side of Starter Switches on Control Room Switchboard.

- Though No. 3 'Starter' Switch (assuming that No. 3 Horse is a Starter and the switch has been closed) to the Betting Circuit Switch on No. 3 Win Horse Unit Fuse Board.

- Through Betting Circuit Switch, Betting Circuit Fuse, Escapement Cutout Relay Contacts, No. 2 Escapement Fuse to No. 2 Escapement.

- From No. 2 Escapement to No. 3 Contact on the Win Horse Selector Segment of No. 22 Issuer.

- From this contact through Horse Selector Brush (which will be on this Contact if Handle has been depressed in No. 3 Hole in the Selector Plate and with the Handle Knob in the outer or 'Win' position) through Handle lock Switch (which will close when Handle is depressed) through Trip Coil, Trip Switch, Issuer Switch, and through Win-Place Selector Switch to 'Win' Contact (Switch will be in Win Position if selector handle is in Win Position)

- From Win Contact on Issuer through Win Pole of No.22 Issuer Common Switch on Distributor Board through coil of No. 22 Win Relay, to No. 2 Stud of No. 2 Win Distributor.

- From Common ring of No. 2 Win Distributor to No. 2 Escapement on Win Grand Total Unit through No. 2 Escapement fuse, through Escapement Cutout Relay Contacts, Betting Circuit Fuse and Betting Circuit Switch.

- From Betting Circuit Switch on Win Grand Total Unit to Contacts of Win Contactor (which will be closed if Machine is open for betting) and thence to + side of Main Betting Circuit Switch.

When the Issuer Handle is depressed therefore, the circuit is complete except through the Distributor which completes the circuit as soon as it reaches No. 2 stud. No. 22 Win Relay will then instantly close and so maintain the circuit. The bet will be registered No. 2 Escapement of the Win Grand Total Unit and No. 3 Win horse Unit and the Issuer Trip Coil will function to start the Issuer and open the Betting circuit again.

So ends the Betting Circuit Drawing No. 3509 extract.

The Common ring, mentioned in item seven in the list of eight items above and prior, is also mentioned in the drawing at the top of this page. In that drawing, below the underlined title WIN MACHINE top centre, is a box labelled Grand Total. Eight wires can be seen descending from this box numbered 6 3 5 2 4 1 8 7. They are grouped together in a downward pointing bracket to the text 8 Wires to common on top of Rings of the 8 Win on top of Distributors above through 14 Ohm Re- above sistors, which put together reads 8 Wires to common Rings of the 8 Win Distributors through 14 Ohm Resistors. Below this in the blueprint drawing at the top of this page, is a similar box labelled Grand Total above the words PLACE MACHINE with Eight wires rising from this box numbered 7 8 1 4 2 5 3 6 which are grouped together with an upward pointing bracket to the text 8 Wires to common Rings of the 8 Place Distributors through 14 Ohm Resistors. These boxes labelled Grand Total in the image at the top of this page, represent the Grand Total Fuse Boards, shown in the blueprint drawing below titled Julius Poole and Gibson blueprint, for the Win and Place pools. There is a detailed drawing of a Grand Total Unit and a Grand Total Fuse Board, on the left hand side of the image below labelled Julius Poole and Gibson blueprint, which can perform the function of either the Win or the Place Grand Total Unit. The 8 wires from the common rings, are connected to the 8 pads in the connector above the label Escapement Terminals at the bottom of the box labelled Grand Total Fuse Board in the blueprint drawing below. The Grand Total Units with their associated Fuse Boards, like the one shown in the blueprint drawing image below are wired to the common ring of the distributors as the Grand Total Unit for a particular Pool must count all transactions for that pool, no matter which runner has been selected by the TIM, which is presently being scanned by the distributor arm passing over the stud the TIM is connected to. This is discussed further in the paragraph after the next. The Grand Total Unit in my time was called a Grand Total Adder.

As a reminder, the left hand side of the blueprint drawing below titled Julius Poole and Gibson blueprint, which is drawing number 3503, shows detail of the Grand Total Fuse Board and the Grand Total Unit. The right hand side of the blueprint drawing below shows the Gear Box Fuse Board and the Gear Box. The Gear Box Fuse Board for the Place pool is represented in the image at the top of this page as a box to the right of the bottom Grand Total box for the Place pool labelled Gear Box. Below this box in the image at the top of this page, is the text Gear Box Fuse Board Drg. No. 3504, just above the bottom edge of the image, which is shown in the bottom right hand quadrant of the image below titled Julius Poole and Gibson blueprint. I presume the right hand side of drawing 3503 below became drawing 3504, alternatively drawing 3504 may have been later included in drawing 3503. The Win pool Gear Box in the blueprint drawing at the top of this page is shown to the left of the top Grand Total box for the Win pool labelled Gear Box, in the top row of boxes, left of centre of the drawing. When I first read the names Grand Total Fuse Boards and Horse Unit Fuse Boards, it conjured up images of boards with the more common electronic glass tube fuses with metal caps. I have seen images of Julius Tote Mainframes relating to the vintage of the blueprint drawings presented in this page as well as the Automatic Totalisators Limited Description of Electrical Circuit Diagrams document and, although I could have guessed it, I was surprised to find that these were not the fuses implemented in these boards. Instead they look like the type using porcelain fuse wire holders that plug into the porcelain sockets mounted on the board which are common in 240V home Fuse Boxes. This can be seen in the image below and is not surprising as the Julius Tote is powered by 120V DC.

Image of part of the Harringay Julius Tote in Museum Storage