More after the Image...

Click on the image to go back to the photo gallery

If you arrived from navigating the website, use the navigation bar at the bottom of this page.

This is an Automatic Totalisators Limited Photograph

Copyright © 2014 Email - totehis@hotmail.com

This image shows the business end of a totalisator system. It is outside the windows where these machines were in operation that the punters queued up to lay their bets on the totalisator.

This is an image of a J8 TIM (Ticket Issuing Machine). This is a later model to the ones I am familiar with as it supports the Forecast pool as well as the Win and Place pools. The J8 is a significant machine as it probably had one of the longest lifespans of any of the TIMs manufactured by Automatic Totalisators. I remember them well as my PDP 11 tote systems with their J22 TIMs, replaced the Julius totes on the Brisbane tracks, which were predominantly using the J8 TIMs. Win-Place only versions of this machine were strewn all around the tracks that I worked on. In many locations around the tracks they remained, in no longer required locations, for at least a decade after their last operation, some lingered a lot longer.

More after the Image...

Click on the image to go back to the photo gallery

If you arrived from navigating the website, use the navigation bar at the bottom of this page.

This is an Automatic Totalisators Limited Photograph

Following is a comment made in 1999, from Joe Brandon, who worked for Autotote, which was Automatic Totalisators Limited's American subsidiary, in which he mentions the J8. I started with Autotote in 1974 at Dania Jai Alai. Ted Taylor (from London) was my boss. I cut my teeth on the J8. I'm now the manager at Atlantic City. Additionally Joe made the following observation in January 2015 relating to some tools, which he used to perform maintenance operations on the J8s: While looking at the J8 in the photo Gallery, it occurred to me I still have my latch up wrenches as well as my original ball peen hammer and punch (for replacing platen pins). The wrenches had to be thin to adjust under the halo. The Halo that Joe refers to is an arc of electrical contacts that sits under the graduated arc on top of the machine. The Horse Halo can be seen in the image below titled The bottom of a J7 TIM (Issuer) Showing the Horse Halo. It can also be seen in the circuit diagram in the first image below near the bottom to the right of centre where it is blatantly obvious and is labelled Horse Selector Quadrant.

Additionally, in 2015, Joe related how the J8 featured in his meeting Sue, his wife to be. He wrote The story is kind of legend here especially with old Autotote folks and I agree, it is the stuff of legends. Joe's anecdote:

One story I never told you and it has to do with the J8 and how I met my wife. We were installing Miami Jai Alai in 1974. At that time, we had designed what we called a black box which allowed us to interface the J8 in combination with the J11's to our PDP8 computer system and this was the first time we used the configuration. I rewired the plant with Don Raison's son Geoff. After setting up the line right outside the computer room, I was told opening night I would in fact be running the lines in what was called the TV room which was to the right and behind the court.

Now of course, you know what a J8 looks like and on our stands it sat about 3 1/2 feet high or so. When I walked into the room that night there was a young lady selling at the first machine. Let's say she was well endowed to say the least and those puppies were just resting happily and covering half of the top of the J8. Suffice to say I didn't wander far that night and Sue and I are now married, almost 40 years now. True story! If it wasn't for Autotote, I wouldn't have her, that's for sure.

Joe adds the following regarding his wife Sue, She is part of the history in more ways than one because she ended up being one of the greats, as to TIM technicians we had at the other company. Worked for them for over twenty years with me and actually worked her way up to running the Tote at Freehold when I took over the Atlantic City hub. She is actually in charge of our Maintenance Department here in Las Vegas now.

Joe also mentions a type of J8 that must have looked impressive. I'm trying to locate an old picture of me with a J8 back in "74". I hope I can find it because that particular machine was part of a shipment we received, I believe from South Africa at Ft. Pierce Jai Alai the year it opened. The really interesting part is the frames on those machines were brass instead of cast iron.

Joe also provides an interesting insight into dealing with problems on an electromechanical Julius Tote: One good memory of the electro mechanical system. At Ft. Pierce, the WPS, Quin and Exacta were belt driven with the brushes rotating on the commutator as the wagers came in. If the belt broke, especially at Jai Alai, you didn't stop to change the belt. You used your finger to rotate the brush until wagering stopped then you had about 20 minutes to change the belt. Note: WPS is Win Place and Show pools.

I mentioned Graeme Twycross' observation in the Melbourne Cup chapter of this website, about ATL's obtuse concept of portable, to Joe. Graeme stated that ATL would attach handles to anything regardless of weight, to classify it as portable. I also informed Joe that if I had to move a J22, during the period that I worked with them, mainly during the 1980s, I would get someone else to take the second handle. If I did move one on my own it was only a short distance. Joe replied with the following paragraphs:

Man, those J8s were heavy! 85lbs. if I remember right. But there was a heavier one than that. I believe we put the first computer system into Roosevelt Raceway ("59" I think?). It was DEC's first computer as used by us. Webmaster's Note: ("59" I think?) probably should be 1969 as the first DEC (Digital Equipment Corporation) based tote we developed was in 1968. After that meet, there was litigation of some sort (between DEC and ATL), of which I never knew the details per say. Anyway, I was sent to the Wilmington office in I believe "76" or so, give or take a year and while there, was assigned to help pull out of storage something called the J10. It was like a J8, frame wise, but bigger and had push buttons on the right and telephone relays mounted inside (I think I'm right on this. Memory gets fuzzy sometimes). They had just been released in conjunction with the litigation I mentioned above, I believe because it was proven they were definitely developed by Automatic Totalisators.

We actually converted them to be used on the PDP8 system with the same relays as we used in the J11. Anyway, those things were even heavier than a J8, if one can believe that! Somewhere around 97lbs. or so.

I was actually working in the shop when they pulled out the J10's. Heavy as hell as he stated. One funny thing occurred when one of the techs. I believe it was Sam Abelman opened the first one and a mouse jumped out. Scared the hell out of him. I remember they had a cage or box inside with old telephone relays like what we used in our old lampboxes. If memory serves, we replaced that with a relay rack something like the J11s. I believe these went to a track somewhere in the Caribbean Islands.

When I started in Feb of 74, Ted was the manager at Dania Jai Alai. He also managed Rocky Mountain Dog Track, Sodrac Park and Jefferson dog tracks. At the time Jean Melanson was the manager at Miami Jai Alai and Don Raison was the head of Field ops. We also had a French Canadian named Mel Parsons who ran tracks up in Northern Canada and Burl Knopp who managed the old Key West J8 installation. Ted was already an old timer when I came along.

Finally, a contemporary note from Joe relating what he is up to in 2015:

I'm still in the business. I left Autotote/Sci-Games ten years ago and I'm now running the tote for Las Vegas Dissemination. It's basically the same system I've been working on forever. The company started out as Autotote CBS and then went private. The owner is the son of the owner of a major casino here who actually at one time owned all the Coast properties. Even cooler, I was able to slip right in as we bought the license to 3 systems from Autotote so I'm really at home with it. We also have 4 programmers here who were with the other company to boot.

It is interesting to note that The Royal Turf Club of Thailand continued to use the electromechanical Julius J8s as the on-course ticket issuing machine up until October 1995, 3 decades after the advent of the electronic computer totes. Manufacturing of the J8 started in 1945 at ATL's Chalmers Street Factory and continued at the Meadowbank factory when it opened in 1947. This means the The Royal Turf Club of Thailand was still using this type of TIM half a century after they first went into production. They were a very good design!

I only worked on the electronic generations of totalisators so I have no experience with the electromechanical ones. Despite this, from my experience the J8 is probably the most iconic and famous of all the TIMs. I have had large numbers of tote operations staff work for me and met many others from different states. It is amazing how, when talking to sellers with long service, their face lights up, and they become animated, when recalling their early years working with the J8.

The TIM has an arc on the top, graduated with runner numbers. To select a runner number the handle is rotated to the desired runner number or combination for the Forecast pool and the knob on the handle is moved outwards to select the win pool or inwards to select the Place or Forecast pools. In this inward position another knob on the top of the machine to the left of the arc, labelled P and F selects the Place or Forecast pools. When the selection is complete the knob on the handle is pushed down initiating a transaction cycle and the handle is locked for the duration of the cycle. On completion of the transaction cycle the handle is unlocked so the next customer can be served. At the top right of the machine, there is an on off switch and to the left of that a handle release button. The handle release button is used if, due to some fault condition, the transaction cycle does not complete properly leaving the handle permanently locked. The Handle Release, Double Pole Switch is mentioned in the table below titled Sequence of Operations & Parts Fitted. Three sample tickets are visible on top of the machine, above the ticket chute from whence they were issued. All three tickets are Race 6 costing 5 Shillings with the left one being on the Win pool on runner 13, the middle on the Forecast pool on combination 3 and 4, and the right hand ticket the Place pool on runner 4. Down the bottom right corner of the machine are three ticket counters for Win, Forecast and Total.

Following are some observations regarding the J8 TIM from Chris Robertson, the most informed punter on the subject of totalisator systems I know. He refers to me not having seen a J8 in operation, despite my having worked on the system that replaced them:

You really missed something there! A house full of J8 machines flat out was something to behold - and to hear. The depressing and release of the issue button had a sound of its own (clackety-clack), and when a whole bank was in action there was plenty of sound. Swinging the machine's dial looked a lot more fun than pushing buttons on the J10.

An interesting place to watch the J8 in action was at Ireland's greyhound tracks. The machines were configured to sell win, place and forecast (exacta) at all windows. This could be done because, as in the U.K., Irish greyhound field sizes were limited to six runners. The first six positions on the dial's arc were occupied by the numbers 1 through 6, and the next fifteen by the various possible combinations, starting with 1-2, 1-3, 1-4, 1-5, 1-6, 2-3, 2-4 and so on. If the customer wanted a forecast with the higher number winning, the button was depressed in the 'place' mode. A boxed combination was sold as an 'each way' bet. I saw the J8 at Cork, Waterford and Dublin's Shelbourne Park; while earlier Julius machines were in action at Dublin's Harold's Cross (as at London's White City). This was way back in 1979.

My J8 Ticket Issuing Machine pamphlet gives the following information regarding pools.

POOLS

The different combinations of pools that can be operated from a J8 Ticket Issuing Machine are:--

This section contains extracts from a company document titled Automatic Totalisators Limited Description of Electrical Circuit Diagrams dated 15/5/1935. This document was kindly provided by emeritus Prof. Bob Doran who photographed the document when he was researching the Julius Totalisator, which was still present at Riccarton Racecourse in Christchurch New Zealand. Note that this old document calls the scanners distributors and the TIMs are called Issuers. The complete transcript of this document, from the images of it that Bob sent, can be read in another page in the Photo Gallery of this website. To read this, click on the image at the top of this page, scroll up in the Photo Gallery index to the heading Early Factory Images and then select the blue image thumbnail above with the first sentence of the associated text being This is a technical drawing showing Julius Tote interconnections. Additionally the drawings and lists presented below are extracted from a 55 page Automatic Totalisators Limited document detailing the assembly, wiring and test procedure for J8 Tims for Randall Park in Ohio, which mentions the year 1950. Essentially machines for America differed from those used in Australia in that they supported an additional pool called Show. Also as the Randall Park system installation was in 1950, by then the TIMs had a high or low value selectable on them.

Another significant difference between these J8s is in the runner selection. In the image at the top of this page, the runner selection arc that the runner selection handle sweeps around, is graduated up to runner 30 for the Win and Place Pools. Alternatively it can be used for the Forecast Pool with races having up to 6 runners. This was not the case with the TIMs for Randall Park where the arc was divided up into two halves. As can be seen from the Issuer Specifications presented below, the maximum number of starters supported is 12. This makes it possible to divide the runner selection arc in two. The top part of the arc is used as normal for selecting runners 1 to 12 for the Win and Place pools. This frees up the lower part of the arc for selecting runners 1 to 12 for the additional Show Pool. The Show Pool runners can be seen in the lower half of the arc in the drawing below labelled J8 OPER NO. 34 Randall Park. The word SHOW appears above this group of runners with an arrow pointing down towards the runners. Also the words WIN PLACE are above the word SHOW with an arrow pointing up towards the Win/Place runner selections up to 12.

Following is a collection of extracts of things Neville Mitchell, a long serving ATL Manager and Engineer said about the J8 and Randall Park, extracted from the Memories of the factory continued chapter of this website:

The wonderful J8 machine. I have no idea of how many they manufactured, but it was certainly in the tens of thousands. In late 1945, the company started in earnest to design totalizator equipment for post war use and, at this time, the J8 ticket issuing machine was born. The first batch of J8 Win, Place ticket issuing machines was installed on Randwick Race Course in 1948. The delivery of these ticket issuing machines to Randwick released a quantity of the existing J6 ticket issuing machines for despatch, along with some 2-shaft adding units, to the United States for use at Randall Park Racetrack. This was a stop gap move and in 1950 the company installed new equipment on this racetrack. That same year an associate company, Automatic Totalisators (U.S.A.) Ltd. was formed to purchase equipment from the parent company and lease it to racetrack operations in the U.S.A. This Company became a subsidiary and by 1967 the company had 23 operations in the United States and Canada. Up until October 1995, The Royal Turf Club of Thailand continued to use J8s as the on-course ticket issuing machine.

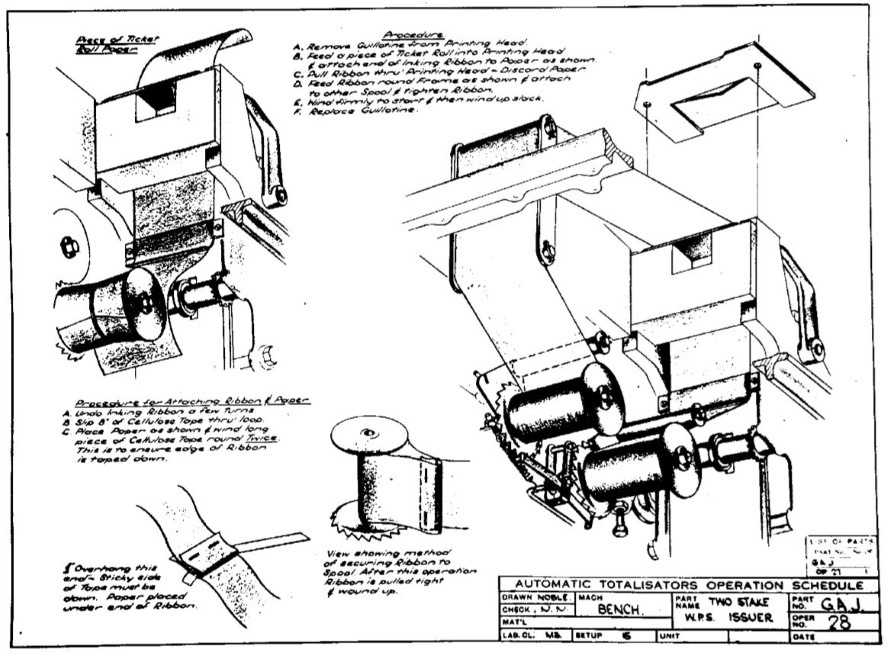

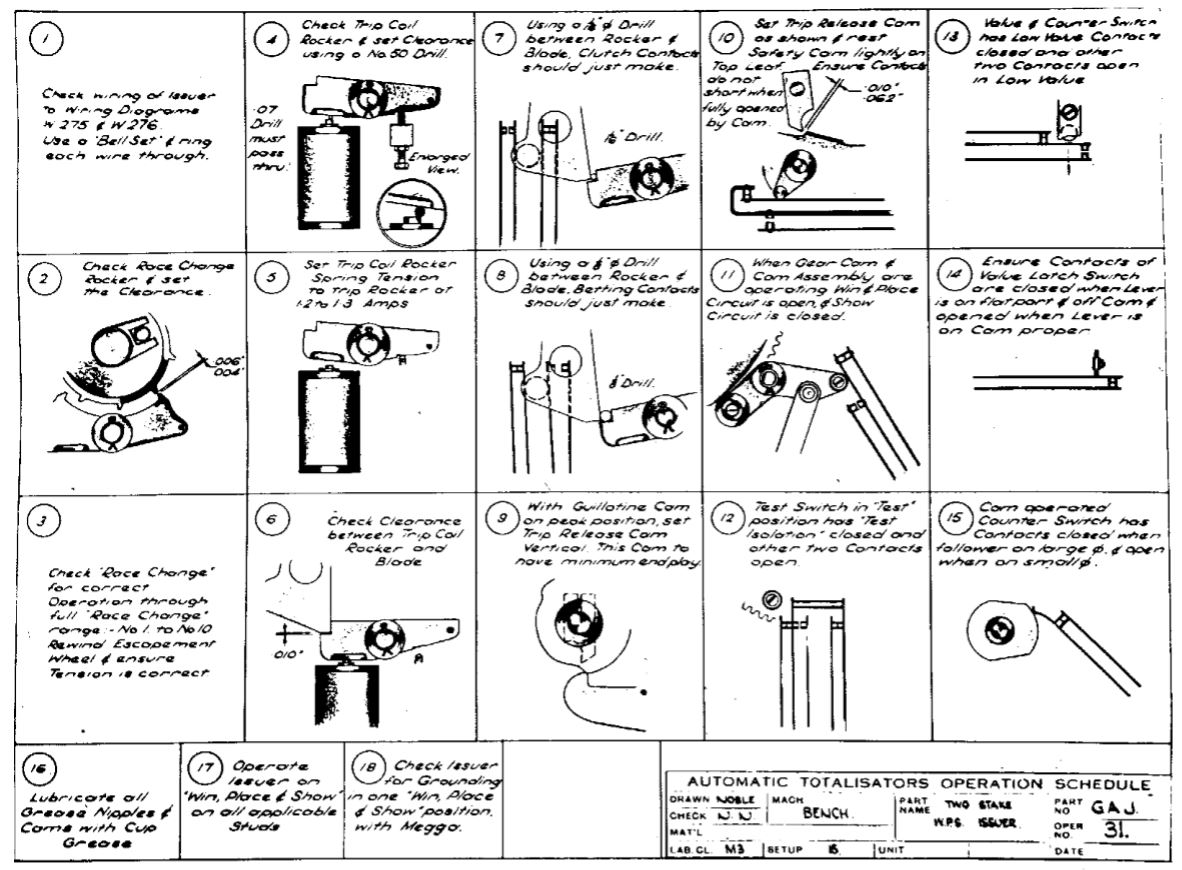

The drawing shown in the image below titled J8 OPER NO. 7 Randall Park has 7 inside a rectangle in the bottom right corner of the drawing titled OPER NO which is embedded in the name I have attributed to this image and all other similar images. It also has G.A.J. on the PART NO. line. G.A.J are George Alfred Julius' initials. Additionally in this identification rectangle titled AUTOMATIC TOTALISATORS OPERATION SCHEDULE at the bottom right hand side of the drawing, the draughtsman's name Noble can be seen to the right of the word DRAWN. This is Norm Noble, a long serving Automatic Totalisators employee. I remember him very well. He was a very charismatic character and although it was not his responsibility to do so I could always rely on him as a last resort to go to work in Sydney on weekends, public holidays, or otherwise out of hours to send me anything I needed in Brisbane. There is a photo of the ATL drawing office in the "Memories of the Factory" chapter that pre-dates my time which has Norm Noble in it, unfortunately he is facing away from the camera. You may have noticed, however Norm has also checked his own drawing as in the CHECK box below the DRAWN box, are the initials N.N. which belong to Norm Noble!

As these drawings relate to the Randall Park J8 TIMs, I have included the following extract from Rod Richards recollections of working at the Meadowbank Factory. Rod worked for Automatic Totalisators Limited as an apprentice and later an engineer in the late 1940s and early 1950s. Following is the extract:

On my first day at ATL I was introduced to man in charge of the Adders, Fred James an old Tote man whose first words were 'Rod, I do not care how long it takes, but it must be done right' I still remember those words as I still tend not to take short cuts. Although 'take your time' was not quite right as Totes was at the time super busy with a number of jobs in the pipe line and overtime being worked. I recall that towards the end of the year 1949, the Randall Park job in the USA was top priority as it had to be completed before a certain date to meet the racing carnival or severe penalties would apply, I think we even worked Boxing Day and air freight was involved.

The tables and all the drawings below come from a fifty five page Automatic Totalisators Limited document with the following information on the first page.

DATE : 12.9.50.

Note the archaic spelling of issuing above. Additionally, I find it interesting that Automatic Totalisators Limited issued documents to particular staff members. In the above case S. Huss from the Assembly Section. These were usually well presented booklets having a substantial cover, with the employee's name on it. I had an old company manual in one of my desk drawers at work in my office in the Old Main Tote House at Eagle Farm Racecourse for many years, which contained the tote maintenance area, the computer room and offices. The manual provided technical details related to a piece of equipment belonging to the Julius Tote era and was of no further value. The manual related to a product called Visitel, which was an electromechanical device that transferred writing on a transmitter unit which was printed on a receiver unit, both units being connected by electric cables. I kept the manual as I was impressed by the workmanship involved in producing it and that it demonstrated the principle of issuing manuals to specific employees, which I have never seen anywhere else. This manual was dedicated to Frank Ryan, who was the predecessor of the last Chief Engineer of the Brisbane Julius Totes, who I knew well, Charles Barton.

Finally, I find it quite amazing how so much was hand drawn prior to the advent of the CAD/CAM systems and finally the Personal Computer that put an end to the busy Drawing Offices producing all these drawings. I remember the impressive drawing offices at AWA (Amalgamated Wireless Australasia) where I worked in the North Ryde Factory and ATL (Automatic Totalisators Limited) in the Meadowbank Factory where I later worked. Neville Mitchell wrote the following which is set in the 1960s, in his memories of the Meadowbank Factory, which are contained in two chapters of this website: They put it together and they made the first basic computer tote system where they could go around to the people like the Hong Kong Jockey Club and say we are looking at computerised multi pool type systems and at that stage I was elevated to Drawing Office Manager. I was controlling 27 draughtsmen and trying to update the systems that were there so that we could cover larger projects.

On the second page of the General Assembly document, there is a drawing of the final product with the following specifications in the bottom right corner:

Issuer Specifications

Randall Park Installation

J8. Issuer

Two Stake $5 & $2

Three Pool Win. Place Show

Number of Starters-12

30 Horse Quadrant

Maximum No. of Races-10

Variable Code Wheels

Fixed Date

Wiring Diagram W275 & W276

Two Total "Electric" Veeders

Ribbon Colour - Blue

Test Coil Resistance - 58 Ohms

Trip Coil Setting - 1.2 Amp

Condenser 2N.20P.

Horse No. Type Leoo

This document has many pictures drawn of the J8 TIM in progressive stages of assembly starting with just the baseplate with four legs attached to it, to make access to the baseplate easy, raising it off the bench. This baseplate sitting on its legs, with a considerable level of assembly already performed can be seen in the drawing below titled J8 OPER NO. 7 Randall Park.

| 1 Type Wheel Peg & Frame | 23 Other Side of Issuer Wiring Former |

| 2 Type Wheel & Win, Place, Show Arm Assembly | 24 Selector Quadrant & Wiring |

| 3 Locking Rod Assembly & Ribbon Bracket | 25 Win, Place, Show Arm, Anchor & Spring. Show Switch Bumper Assembly. Pool Selection & Bracket. |

| 4 Intermediate Gear Bracket & Gear | 26 Condenser & Clips |

| 5 Handle Assembly. Handle Stop & Brush Holder | 27 Motor & Brushes, Chain & Split Link. |

| 6 Taper Pinning Operation | 28 Ribbon Feeding Operation |

| 7 Platen Assembly | 29 Issuer Box & Hinge &Wiring Clips |

| 8 Win Place, Switch Assembly & Slide Rod | 30 Plastic Issuer Handle , Pin & Circlip |

| 9 Paper Feeding Assembly | 31 Electrical Setting Details |

| 10 Trip Coil Assembly | 32 First Test |

| 11 Ribbon Rewind | 33 Taper Pinning Operation |

| 12 Quadrant Supports, Issuer lifting Handle & Posts & Cover posts | 33A Ticket Issuer Chute |

| 13 Handle Release, Double Pole Switch & posts, Test Switch, Handle Release Lever & Spring | 34 Covers & Horse Number Segments. |

| 14 Test Coils, Wiring Brackets & Cover Catches | 35 Final Test |

| 15 Latch switch & Show switch | 36 Spray Finish issuer Box. |

| 16 Cam operated Counter switch | 37 Attach Nameplate |

| 17 Guillotine Lever, Anchor & Spring Printing Lever, Anchor & Spring | 38 Clean & Inspect Box |

| 18 Value Slide Lever & Spring | |

| 19 Rotary Switch, Retaining Posts & Value Leaf Switch Assembly | |

| 20 Value Release & Spring | |

| 21 Veeder Assembly | |

| 22 Issuer Wiring Former & Brushes |

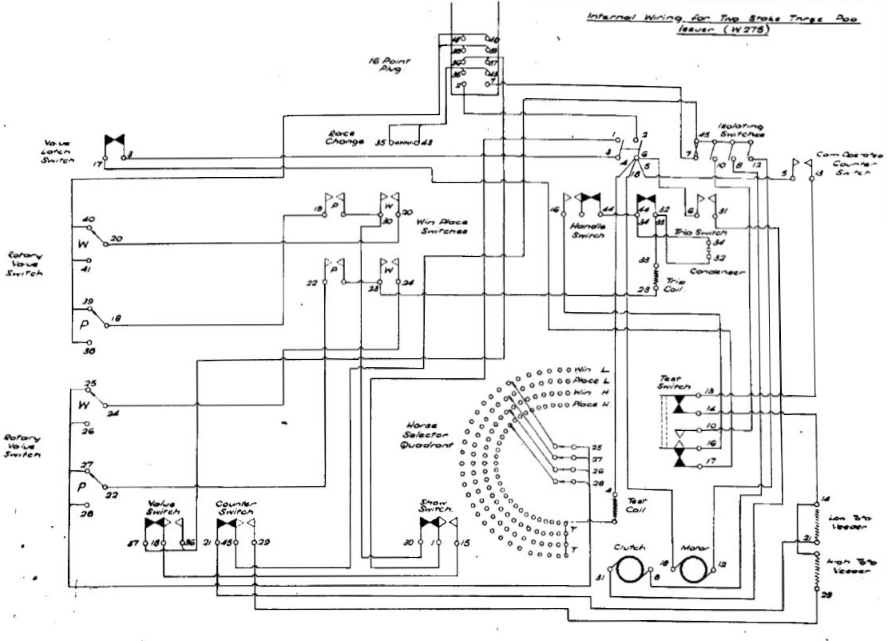

The image below has a title in the top right hand corner that reads: Internal Wiring for Two Stake Three Pool Issuer (W275). Actually, the title in the drawing has no L on the end of the word Pool, however I have corrected that in the title I have presented because I am sure it is not a Three Poo Issuer! Please excuse the jocularity, sometimes needed to lighten up the laborious task of wading through circuit diagrams and descriptions! This issuer is a Two Stake issuer as it has a value switch that can select one of two values for the transaction. The Rotary Value Switch can be seen in two parts on the left hand side of the drawing below. Up against the left hand edge of the drawing below there are two instances of the label consisting of the words Rotary on top of Value on top of Switch. The top instance of Rotary Value Switch is on the left hand side of the two arms of the switch, the top one labelled W for the Win Pool and the bottom one labelled P for the Place Pool. This part of the switch selects the appropriate connection pins in the 16 Point Plug shown top centre of the drawing below. The bottom instance of Rotary Value Switch is on the left hand side of another two arms of the switch, again the top arm for the Win Pool and the bottom for the Place Pool. This lower part of the switch selects the appropriate pair of contact arms in the semicircular device near the bottom, to the right of centre of the image below labelled Horse Selector Quadrant.

The circuit diagram shown in the image below has little circles I call pads, drawn in the conductor lines to represent joins. These pads all have numbers associated with them. These numbers relate to the wire numbers titled Wire No. in the table below titled General Assembly of Randall Park issuer Wiring Information.

As mentioned, the Randall Park J8s accommodated the Show Pool. This is selected by an additional switch added to the J8. It can be seen in the Circuit Diagram above with the label Show Switch, which can be found to the left of the Horse Halo below the text Horse Selector Quadrant, which is synonymous with Horse Halo. The J8 at the top of this page, as previously mentioned supported an additional pool as well, to the normal Win and Place, only instead for the Show Pool it is the Forecast Pool. The switch seen in the top left quadrant of the J8 in the image at the top of this page, that is marked P at the top end of its travel and F at the bottom end of its travel, changes a Place Pool bet to a Forecast bet, if the switch is in the lower position. The Show Pool switch shown in the Circuit Diagram above, will have been implemented by the same switch as the one just described in the image at the top of the page, except that instead of F for Forecast it will have been marked S for Show.

Below and to the left of the 16 Point Plug in the Circuit Diagram above, is a coil winding with the label to the left of it reading Race on top of the word Change. The number on the left side of the coil reads 35 and on the right 43. This is the Race Change Coil. This coil activates the escapement rocker for the Race Change escapement wheel which rotates the Race Number Stamp to the next race to be run when required, so that the J8 prints the correct race number on the tickets. This Race Change escapement wheel can be seen in the image below titled J8 OPER NO. 7 Randall Park on the left hand side of the assembly labelled SAJ203. The Race Change escapement wheel and rocker is visible in the image near the bottom of this page titled J8 OPER NO. 31 Randall Park in box number 2, which shows the clearance required for the rocker. This sketch in box 2 does not show it, however the Race Change Coils of which there are two with a single winding are installed directly below the rocker in the sketch as the magnetic field the Race Change Coils generate operates the rocker. Following is an extract from a talk Neville Mitchell gave about the Julius Totes, which is presented in the The Premier Tote Operation 1930 + Neville's talk chapter of this website and the barrels he mentions which had 8 or 10 positions, have the race number stamps on them:

The other coil you will notice in the J8 is the race change. This is the same sort of set-up and it had a barrel, most of the barrels had 8 or 10 positions. It was a die cast aluminium barrel which had the numbers 1 to 8 or 1 to 10 on it and there was another barrel associated with that called the code barrel. These codes were kept secret and they were only issued out a few minutes before the first race at any race track and the code barrel was lined up in a special way. The mechanic in charge of the tote house would be given a box with all of the code barrels and race barrels in it. He would then open an envelope when he got to the tote house and it would tell him the code of the day so he knew which code on the barrel to start with. He inserted that and then wound the clockwork mechanism of the race change back to race one. At the end of race one, the race engineer, the person in charge, or the totalisator manager for the day, would call up a race change and a push-button was operated in the main control room, which caused all of the ticket machines to rotate to race two and consequently show not only the race number but the new code word.I think it was Ron Findlay, who was a technician with Automatic Totalisator Limited, who told me that when the current race number was incremented on the RDC (Race Day Control) console all the TIMs received the signal to rotate the race number barrel inside their printers and if you were in a tote house which had a significant number of machines in it, then it was quite impressive to hear them all clank in unison.

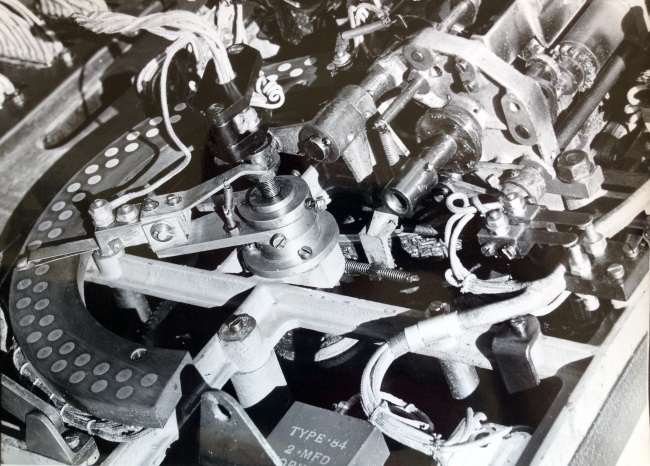

Below and to the right of the 16 Point Plug in the Circuit Diagram above, there is a group of three switches labelled Isolating Switches. To the left of these four switches is a fuse with the number 45 on top and the number 7 below. This fuse along with the three switches are located on a board of their own, which is connected to the bottom right hand side of the case on the inside. When the top of the J8 is lifted by the hand-grip at the back, it hinges open on the hinge seen running across the width of the front of the J8 at mid height level. This hinge can be seen in the image at the top of this page. This is the maintenance position of the machine exposing all the component parts and the switch and fuse board mentioned inside the case is easily accessible. The two right hand switches on this board control the power to the clutch and motor seen as two large circles in the bottom right quadrant of the Circuit Diagram above. The motor can be seen as the largest cylindrical object in the image below titled J8 OPER NO. 27 Randall Park . In the J8 in my collection this motor was manufactured by a sizeable Australian company called Airzone founded in 1926. The drive shaft out of the motor on the right hand side connects to the cylindrical magnetic clutch.

In the bottom right corner of the J8 TIM shown at the top of this page three counters can be seen marked WIN and FORECAST side by side, with another marked TOTAL underneath. These counters allowed the operator's takings to be balanced. These counters in the Randall Park J8s were electromechanical counters manufactured by Veeder Root. Veeder Root mechanical counters were also used in the Adders and the Australian J8 I have in my collection also has the mechanical counters. In the bottom right hand corner of the Circuit Diagram above, two windings can be seen, one on top of the other. These are the Veeder Root counter windings. Like the J8 TIM shown at the top of this page these counters total the number of sales on the American version of the J8, however instead of dividing the sales into Win/Place and Forecast pools like the Australian J8 shown at the top of this page, it divides them into high value and low value. The top of both windings, via pad 14, comes from the switch above and to the left of the counter windings with the word Test on top of the word Switch seen on top of the switch. This switch disconnects the counters from the Cam Operated Counter Switch when the Test Switch is activated, as test tickets are not part of the sales. The Cam Operated Counter Switch can be seen in the Circuit Diagram above near the top right hand corner with connecting pads labelled 5 and 13. The words constituting Cam Operated Counter Switch are very difficult to read even in the original document. They look to me like Cam Operated on top of the much clearer two words Counter on top of Switch. A few words are rather bizarre in the Circuit Diagram above, for instance in the word Operated, the "p" has no bottom half the "r" and "t" have no down stroke and the "d" has no upper half. Despite this I feel confident I have interpreted it correctly.

After having indicated my confidence in getting the name Cam Operated Counter Switch right, I have found absolute confirmation that my interpretation is correct. The Cam Operated Counter Switch appears in the list above titled General Assembly of Randall Park issuer in item 16. Additionally the Cam Operated Counter Switch assembly can be seen in a picture drawn inside a circle titled Cam Operated on top of Counter Switch in the image below, titled J8 OPER NO. 22A Randall Park. The bottom ends of each Veeder Root winding at pads 21 and 29, have conductors attached to them both seen descending down to the bottom of the drawing and then travelling left both jumping up a step before travelling further left and finally rising vertically to join the two end pads of three belonging to the switch with a label on top consisting of the word Counter on top of the word Switch. I have called the little circular connection points on these old drawings pads, as this is what they were called on PCBs (Printed Circuit Boards) although the early Julius Totes pre-dated PCBs. This Counter Switch, switches the power supply which arrives at the circuit above via Pin 7 bottom right of the 16 Point Plug seen near the middle of the top of the drawing. From there a conductor is shown travelling right and then down to the bottom end of a fuse between the pads labelled 7 below and 45 above. From the upper pad 45 a conductor can be seen travelling up then left then down and left again and then through two more down and left steps finally connecting to the switch arm of the Counter Switch. Hence this Counter Switch selects either the upper or lower counter to receive power, which is the means of directing the high value transactions to the high value counter and the low value transactions to the low value counter. The labels to the right of the two Veeder Root windings again are hard to read and look like the word Low followed by something indeterminable, on top of Veeder for the upper winding and Highfollowed by something, on top of Veeder for the lower one. Both labels are located close to the right hand edge of the drawing near the bottom of the page. As previously mentioned, the bottom ends of each of the Veeder Root windings are at pads 21 and 29, which are connected to the left and right pads of the Counter Switch. We can now use the table below titled General Assembly of Randall Park issuer Wiring Information to look up what the names of the Veeder Root windings are. For pad 21 the table records the start as the Low Total Veeder and the end as the Low Counter Switch and for pad 29 the start is the High Total Veeder and the end is the High Counter Switch. We now know the names of the two Veeder Root windings in the Circuit Diagram above, which are shown in the diagram with the Low Total Veeder above the High Total Veeder.

Note that the Veeder Assembly is mentioned in the table above titled Sequence of Operations & Parts Fitted in item 21. The Veeders are also mentioned in the table below titled General Assembly of Randall Park issuer Wiring Information in items 14 21 and 29 as well as item T in the First Test listed below.

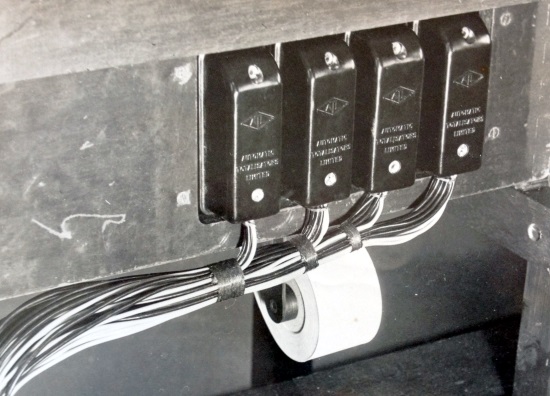

The image below shows the 16 Point Plug shown top centre in the Circuit Diagram above. The ATL diamond logo can be seen on each of these connectors in the image below, as well as the words Automatic on top of Totalisators on top of Limited below the diamond, on each of the connectors. Normally the plugs of this type of connector were connected to the TIMs and the Adders, and the cables emanating from the black plugs seen in the image below probably come from a TIM, as the J8 in my collection has four of these plugs mounted on the back of the case, which is out of view of the image at the top of this page, on the side facing the top left corner of the image. The sockets that the black plugs are plugged into in the image below, which look like they are permanently attached to a wooden cable tray, will have had cables connected to them inside the cable tray, which amongst other connections ran inside the cable tray to the Horse Units/Adders in the Machine Room with the scanners in the machine room providing the activation pulse for transaction cycles. Transaction cycles are performed by mechanical parts that interact with what is called the Betting Circuit. The part of the Betting Circuit that pertains to the TIMs, is described in the company document extracts below. It is interesting to note that the Circuit Diagram above only shows one of these 16 Point Plugs. The other three carry the connections from the contacts in the arcs of the Horse Halo in the Circuit Diagram above to the machine room. A discrepancy exists between my J8 and the Circuit Diagram above in that my J8 does not support two values and supports a maximum field size of 24, which means its Horse Halo has 48 contacts, 24 for the Win Pool and another 24 for the Place and 48 connections can be carried in three 16 pin plugs. This means the image of the plugs below was taken of a system that supported the type of J8 that I have in my collection. The roll of ticket paper seen sitting on a paper dispenser in the image below, confirms that the nearest TIM is not far away, probably on top of the bench vertically above. Below the ticket roll seems to be the floor level, the level at which the operator's feet will rest. Actually, I bet the odd operators foot has rested in the angled wooden support for the cable tray, seen at the right hand lower edge of the image above! The slot below the displayed tickets shown in the image at the top of this page, is where the tickets are ejected which are printed on and cut from the ticket paper like that shown on the roll in the image below.

Some Plastic Moulded ATL connectors

In the extract below titled BETTING CIRCUIT./ Drawing No. 3509., the first paragraph relates to the circuit through each horse unit. The Horse Unit in this old document is what is referred to in the rest of this website as one of the many Shaft Adders in a Julius Tote installation. These are an integral part of the mainframe. The escapements mentioned refer to the escapement shafts containing escapement mechanisms and escapement wheels that record transactions from the TIMs which are summed by epicyclic gears on the adding shafts on the adders. From a simplistic functional perspective, as opposed to implementation, I see the TIMs as the start of the BETTING CIRCUIT, as nothing happens on a Julius Tote except for the rumbling of the mainframe drive motors and scanner drive motors in the machine room, until someone buys a ticket, which is issued from the TIM. In this view, the end of the BETTING CIRCUIT is the Adders where the transaction is recorded and the bit in between is the Scanners/Distributors and associated equipment, which constitutes the front end system that interfaces the TIMs to the Adders.

Following are extracts, pertinent to the TIMs from the Automatic Totalisators Limited Description of Electrical Circuit Diagrams document.

The circuit through each horse unit is then as follows -. Through the Betting Circuit Switch and Fuse and through the normally closed contacts of the Escapement Cutout Relays (the operation and purpose of these relays is described elsewhere) to the common side of the escapement fuses, there being one fuse for each escapement and thence to the escapements.

From the escapements the circuit now proceeds to the corresponding contacts on the Horse Selector Segments of the corresponding issuers, that is the wire from No. 1 escapement on No. 1 Win Horse Unit is looped into the No. 1 Contact on the Win Horse Selector Segments of all issuers in No. 1 Group and so on.

Webmaster's notes

The image below is not part of the Description of Electrical Circuit Diagrams document.In the paragraph above, the Horse Selector Segments are mentioned. Although the following image shows the bottom of a J7 rather than a J8, they look similar. The arc seen with contact studs on it in the image below is the Horse Selector Segments or Horse Halo as it was later called and was used to select the runner number required for the transaction. The arm that sweeps across the arc, or Horse Halo, in the image below is connected to the runner selector handle seen on the top of the J8 in the image at the top of this page.The bottom of a J7 TIM (Issuer) Showing the Horse Halo

The collecting brush which picks up the contacts on the Horse Selector Segments is mentioned in the first paragraph of the continued document extract below and the collecting brush can be seen in the image above about half way around the horse halo. Here the extension of the runner selection handle, seen anchored in the centre of an imaginary circle created by extending the runner selection arc in the image at the top of this page is two metal strips in the image above each extending to a position above their respective arc of contacts, with a contact at the ends of each of the strips, which are the collecting brushes one for each of the two arcs of contacts. The outer arc of contacts are for the Win Pool and the inner arc of contacts are for the Place Pool. Usually, there are as many studs in each arc as the maximum number of runners in a race plus one for printing test tickets.

These collecting brushes are clearer in the image below as the Horse Halo has not yet been installed. They are described in the paragraph below the image below. There are four collecting brushes in that image as it relates to the American Randall Park J8s which supported two selectable values requiring an extra pair of Horse Halo studded arcs and corresponding brushes/contacts.

The circuit through each Issuer, in the first paragraph following these notes, extracted from the Automatic Totalisators Limited Description of Electrical Circuit Diagrams document, can be seen in the image labelled J8 Circuit Diagram Randall Park, above. When trying to match the technical descriptions in the Description of Electrical Circuit Diagrams document which was written in 1935 for a system in New Zealand, to the Circuit Diagram above, which shows the American J8 diagram of 1950, we have to consider that the fifteen years between them and the fact they are systems with differing requirements, make differences between the documents inevitable. In fact, as Neville Mitchell related, the J8 TIM only came into being in late 1945, so the TIM in use at Riccarton New Zealand being described in the 1935 company document will obviously be a prior model to the J8 TIM. A major difference between the two is that the American J8s supported a selectable value, a feature the New Zealand system TIMs and the J8 I have in my collection and any other Julius Tote TIM I have seen, did not have. As a consequence of differences, the sequence of the components in the description in the extract below does not line up with the Circuit Diagram above however the items in the list do match the items shown in the betting circuit in the Circuit Diagram above, all be it in a different sequence, so I have followed the sequence in the Circuit Diagram for the sake of my explanation. To begin tracing the Betting Circuit through the J8 in the Circuit Diagram above lets begin with the Collecting Brush where the description below begins. The Collecting Brush mentioned below is one of four seen in Diagram above at the tips of the arms radiating from the centre of the semicircle called the Horse Halo or Quadrant. At the centre of these radiating arms, the four conductors connect with four wires numbered 25 27 26 and 28. As mentioned, the description below relates to a system that does not have a selectable value on the J8, so it is describing a system that only has two of these contact arcs and only requires two wires to service the arcs. To emulate the system that is being described, let us just consider wires 25 and 27. These two wires in the drawing travel vertically downwards, represented by a single line that then turns left towards the left hand edge of the drawing then rises and connects with one of the two Rotary Value Switches. As we are only dealing with one pair of conductors coming from the Selection Brushes, these value switches do not exist in the J8 being described and we can accommodate that in this description by imagining that conductor 24 is directly connected to conductor 24 bypassing the switch and similarly conductor 27 is directly connected to conductor 22 again bypassing the switch. wires 27 and 22 now head right then rise to join the Win - Place Selector Switch mentioned in the description. One of these switches marked P on the left and W on the right will depend on which pool W for Win and P for Place by the runner selection handle knob. The Betting Circuit continues on wire 23 connected to the two inner contacts of the switches in the drawing that are shown joined together, heading right crossing several vertical wires finally turning upward to immediately join the Tip Coil mentioned in the description. After passing through the Trip Coil it rises again with wire 33 to join one of the Normally Closed (NC) contacts of the Trip Switch mentioned in the Electrical Circuit Diagrams description below. From there the Betting Circuit passes through the (NC) contacts of the Trip Switch and travels a short distance left with wire 44 to join the Handle Switch, which is called the Handle Lock Switch in the Electrical Circuit Diagrams description below. When the second contact of the Handle Lock Switch closes as well a connection with wire 16 on the left is made, as is the case during a transaction cycle and the Betting Circuit continues down, turns right and descends again to the bottom top contact of the (NC) pair of contacts at the bottom of the Test Switch. Finally, the Betting Circuit then passes through these test switch contacts and joins wire 17 which rises again in the Circuit Diagram above, turns left, crosses a couple of vertical conductors and then rises again past the Handle Switch on the right. It then turns left rises a small step and turns left again joining the left hand contact of a (NC) pair of contacts in the Value Latch Switch. Again, as the J8 being described in the Description of Electrical Circuit Diagrams document does not have the selectable value feature this switch does not exist in the J8 being described in the Electrical Circuit Diagrams document extract below so let us assume that wire 17 is connected to wire 3 which is seen heading right to join the bottom left contact of four in the Issuer Switch/Tumbler Switch mentioned in the Electrical Circuit Diagrams document extract below.

Having mentioned the Handle Lock Switch in the last paragraph, I will mention that this switch is arranged differently to all the others. The other switches that have three arms to them in the J8 Circuit Diagram Randall Park above, all have wires attached to all three arms, whilst the Handle Lock Switch shows no wire connected to its centre arm. All switches with three arms show the (NC) contacts of the switch, not only by showing these contacts in contact with each other, whilst the other pair of contacts are not drawn in contact with each other, but additionally by emphasising the contacts that are touching each other by being represented as filled in black triangles and the ones not touching each other being represented by outline triangles only identifying the Normally Open (NO) contacts. With all the other three arm switches in the Circuit Diagram above, when the switch is activated, the (NO) contacts close and the (NC) contacts open. This is not the case with the Handle Switch. This is the only three arm switch in this drawing that can have both sets of contacts closed at the same time, so when it is active wire 44 on the right is connected to wire 16 on the left through both pairs of closed contacts. This now gives us a switch, which can be closed by one pair of contacts by one source, and opened through the second pair of contacts from a separate source. The Handle Lock Switch can be seen in item number 10 in the image below titled J8 OPER NO. 31 Randall Park. Item 10 relates to two adjustments, the Trip Release Cam and the Safety Cam which relates to the lower sketch. The switch in this lower sketch is the Handle Lock Switch, and the centre arm of this switch is rigid as indicated by the thicker line in the sketch and the other two arms are flexible and are pushed to break contact in the case of the upper contacts and pushed to make contact in the case of the lower contacts. Herein is yet another oddity of this switch in that the end of the centre arm is bent upwards then backwards, making it possible to break the contacts by applying force towards the centre contact rather than making contact as is the case with the lower arm of the switch. A potential problem with this arrangement is that if the upper arm is pushed far enough, it will make contact with the lower arm and the switch will be erroneously closed again. This is the reason for the test in the second part of item 10 which reads: Rest Safety Cam lightly on Top Leaf. Ensure Contacts do not short when fully opened by Cam. Do not short, means that the top arm should not contact the middle arm otherwise a short circuit will be caused across them which is the same as the switch being closed rather than open. The (NC) contacts, which are the upper ones in Item 10 of the Handle Lock Switch are opened by what is referred to as the Safety Cam on the Printer Drive Shaft, which when at rest leaves these contacts closed. This Safety Cam rotates clockwise in the direction of the arrowhead arc in the sketch and when it has rotated approximately 280 degrees it will open the contacts, with the Cam's projection on the right hand side of the fulcrum rather than the left and they remain open for most of the remainder of the Cam's 360 degree cycle with the contacts closing again shortly before the Cam comes to rest. I presume this Cam is called the Safety Cam as opening the Handle Lock Switch is a last ditch effort to break the Transaction Circuit if the normal method fails as this would have the potential to disrupt this TIM's Scanner and consequently all the other TIMs in the same group. The (NO) contacts of the Handle Lock Switch are closed by the knob on top of the runner selection arm. When this knob is pushed down and latched in place, indicating a sale and initiating a transaction cycle when the J8 is scanned, the (NO) contacts of the Handle Lock Switch are closed as well.

The circuit through each Issuer is then as follows. From the collecting brush which picks up the contacts on the Horse Selector Segments through the Handle Lock Switch (closed only when the handle is locked down) through the Trip Coil, through the trip switch (normally closed when the Issuer is stationary), through the Issuer Switch (Tumbler Switch on Issuer Cover Plate) to the Win - Place Selector Switch.

From each Issuer two wires (one for Win and one for Place) are taken from the Contacts of the Win-Place Selector Switch to the Double Pole Issuer Common Switches on the bottom of the Distributor and Relay Switchboard and thence through the coils of the corresponding Relays to the Distributor Contacts. There are a pair of relays (one Win and one Place) for each Issuer and a pair of Distributors (one Win and one Place) for each Group of Issuers and each Distributor has 8 contacts corresponding to the 8 issuers in the group.

Webmaster's note: The following title is a list item extracted from the BETTING CIRCUIT./ Drawing No. 3509 section of the Description of Electrical Circuit Diagrams document.

RELAYS ON DISTRIBUTOR BOARD.

There are a pair of relays, one for Win and one for Place for each Issuer.

These relays serve to provide a definite time for the Issuer Trip Coil to function even if the Issuer Handle is depressed just as the Distributor Contact arm is leaving the Contact Stud corresponding to that Issuer.

The relay coil is connected in series with the Trip Coil and escapement magnets and so is energised when the Betting circuit is completed. The relay contacts are arranged so as to short circuit the distributor when the relay closes. Thus the Betting Circuit is maintained when the Distributor Contact arm leaves the contact stud and is only broken by the Issuer Trip Switch. The relay is very quick in operation and will close and so maintain the circuit if the Issuer Handle is depressed just as the Distributor Contact arm is leaving the contact stud.

As the distributors are an essential part of the Betting Circuit I have included another extract from the company document mentioned that gives an example of the path of the betting circuit which obviously includes the path through the distributors.

To illustrate the operation of the Betting Circuit more clearly, assume that No. 22 Issuer is to Issue a 'Win' Ticket on No. 3 horse. The circuit will then be as follows-

When the Issuer Handle is depressed therefore, the circuit is complete except through the Distributor which completes the circuit as soon as it reaches No. 2 stud. No. 22 Win Relay will then instantly close and so maintain the circuit. The bet will be registered No. 2 Escapement of the Win Grand Total Unit and No. 3 Win horse Unit and the Issuer Trip Coil will function to start the Issuer and open the Betting circuit again.

Here we take a break from the BETTING CIRCUIT./ Drawing No. 3509. extracts

In the image above, at the tip of the runner selection arm referred to above, the Win/Place selection switch activating arm can be seen protruding above the runner selection arm. The circular knob on top of the end of the runner selection arm, as seen in the image at the top of this page, can travel a short distance radially along the runner selection arm. This movement moves the switch arm shown in the image above. At the left hand end of its travel seen above, or outer position, it selects the Win Pool and at the right hand end of its as seen above, or its inner position it selects the Place Pool. The switches that implement this function can be seen in the circuit diagram above titled J8 Circuit Diagram Randall Park as a group of four switches arranged in the shape of a square slightly above and to the left of the centre of the diagram. The box is arranged as two rows of two switches each. The switches have letter between the contacts the top pair being P and W which is repeated for the second row. To the right of this group of switches is the label consisting of the words Win Place above Switches.

In the circuit descriptions above the image above, under the heading RELAYS ON DISTRIBUTOR BOARD extracted from the Description of Electrical Circuit Diagrams document, the Trip Switch and the Trip Coil are repeatedly mentioned. These can be seen in the drawing below inside two circles in the bottom half, Trip Coil Assembly on the left and Trip Coils on the right. The Trip Switch can be seen in the centre of the Trip Coil Assembly below with the springy metal strips containing the switch contacts at their tips, pointing downwards. The mechanism behind these metal strips pushes on the nearest of the metal strips in the switch which acts to close the contacts of the switch. The Trip Coil Assembly can also be seen in the drawing below titled J8 OPER NO. 27 Randall Park. It is located at the left rear of the partially assembled TIM, sitting higher than any other assembly in its vicinity. The Trip Switch breaks the Transaction Circuit at the end of a transaction cycle and starts the print cycle in the J8 to produce a corresponding ticket for the customer. In the J8 in my collection, once the trip coil has activated the solenoid to rotate the associated rocker arm, this action opens the normally closed contacts of the Trip Switch, which are for the Betting Circuit and closes the normally open contacts, which are for the magnetic clutch, activating the clutch which starts the printer drive shaft rotating powered by the motor through the clutch. A spring loaded locking lever which looks like it is called a Blade, latches the Trip Switch in this state, by engaging the rocker arm which keeps it in this position until the print cycle is complete. This activation of the Trip Switch marks the end of the transaction cycle and the beginning of the print cycle. After the best part of a revolution of the printer drive shaft, a cam on the drive shaft comes in contact with a flange on the Blade located at the opposite end of its fulcrum to where it is in contact with the Trip Switch rocker arm. The force applied by the cam rotates the Blade around its fulcrum, against the pressure of its spring holding it in place engaged with the notch in the rocker arm, rotating it away from the Trip Coil Rocker allowing the rocker arm spring to return the rocker arm to its rest position. This deactivation of the Trip Switch disengages the clutch, stopping rotation of the printer drive shaft and restores the betting circuit through the J8 ready for the next transaction when it is scanned again. By the time the Trip Switch is reset by the cam on the printer drive shaft, a similar cam on the same shaft oriented about 135 degrees in front of the first cam in the direction of rotation, has already released the Handle Lock mechanism. The Trip Coil, its Rocker and the Blade can be seen in box 6 of the image below near the bottom of this page titled J8 OPER NO. 31 Randall Park. The Rocker has a hole in its right hand end. This is for the spring that holds the rocker arm in its rest position whilst the Trip Coil is not creating a magnetic field. A small part of the Blade seen top left in box 6 is seen engaged with a notch in the rocker arm. The part of the Blade in view is just the tip of a much larger lever. The rocker arm is just short of 6.5 cm long and the Blade is 10 cm long.

The following table exists in the Randall Park document, however it has no title so I have made the following title up. It clarifies the numbers in this document like the ones seen identifying wires in the image below that have small circles around them and lines pointing to the particular wire in question. For instance, in the previous paragraph, I wrote The Trip Switch can be seen in the centre of the Trip Coil Assembly below. It is intuitive to think the Trip Switch is in the Trip Coil Assembly, however the table below provides proof positive. There is a line pointing to this switch inside the Trip Coil Assembly circle emanating from a position near the bottom left corner of the drawing where there are two small circles containing the numbers 34 and 44. Looking at the wiring table below these two numbers are both identified as the Trip Switch confirming the Trip Switch is part of the Trip Coil Assembly. Furthermore, the table below also informs us that the wire numbered 34 that is connected to the Trip Switch connects the Trip Switch which is in the Start column to the Condenser, which appears in the End column. Nowadays, Condensers are called a Capacitors. Similarly looking up the wire numbered 44 in the table below we find this connection goes from the Trip Switch shown in the Start column to the Handle Switch, which appears in the End column. These connections from the Trip Switch to the Condenser and the Handle Switch can be seen in the Circuit Diagram above labelled J8 Circuit Diagram Randall Park.

The wire numbers 34 and 44 already mentioned in the table below and the Trip Coil Assembly drawing shown bottom left of the drawing below titled J8 OPER NO. 22A Randall Park also apply in the circuit diagram mentioned above. This is because all three of these sources come from the Randall Park documentation. For the sake of this explanation, to pick an easily identifiable location on the circuit to start with, I will begin from another point that will lead us back to the Trip Switch, Handle Switch and the Condenser. We can see from the table below that wire number 31 goes from the Trip Switch to the Clutch. The Clutch is easily identifiable in the Circuit Diagram above titled J8 Circuit Diagram Randall Park. Near the bottom of this Circuit Diagram, there are two large circles drawn side by side, the left hand circle is the clutch. The wire number 31 mentioned is connected to the left side of the Clutch. It descends, travels right and rises vertically, then turning right again for a short distance then returning upwards past the mid height level of the drawing, finally turning left and connecting with pad on the right hand contact of a switch. The pair of contacts in this switch are shown in their open position as seen in the hollow triangles at the top of the switch arms. To the left of this is another switch with its contacts shown closed identified by the filled in black triangles at the top of the switch arms. This is the Trip Switch we are interested in. The left hand arm of this closed switch has two numbers on the right hand side of its connection pad which are 34 and 44, the numbers we were aiming to identify. We previously determined that conductor 34 connects the trip switch to the Condenser. We can now see this in the circuit diagram. Wire number 34 travels down from its connection pad in the left hand arm of the closed contacts of the Trip Switch and then turns right a short distance before descending slightly to join a pad also numbered 34 at the top of the Condenser the destination we were chasing. This condenser bears the conventional capacitor symbol which is two parallel lines that represent the electrodes, at right angles to the leads, although in this drawing the electrodes are shorter to what I am accustomed to. The Capacitor in the Circuit Diagram has the word Condenser underneath it. This wire number 34 in the J8 Circuit Diagram Randall Park drawing above, diagrammatically shows the connection shown in tabular form in the table below titled General Assembly of Randall Park issuer Wiring Information. It is now a simple matter to identify the wire number 44. Returning to the left hand arm of the closed contacts of the Trip Switch in the Circuit Diagram above, from the pad in the left hand arm with 44 to the right and above, this conductor travels left from the pad, which we previously followed the downward path. It travels left a short distance crossing two other vertical conductors and then joining a pad also numbered 44, which is in the right hand arm of another switch. This switch has the name Handle Switch below it.

| Wire No. | Start | End | Wire No. | Start | End |

|---|---|---|---|---|---|

| 1 | Tumbler Switch | Show Switch | 24 | Win Place Switch | Win Value Switch(Betting) |

| 2 | Tumbler Switch | 16 Point Plug | 25 | Low Win Value Switch | Low Win Brush Ring |

| 3 | Tumbler Switch | Value Latch Switch | 26 | High Win Value Switch | High Win Brush Ring |

| 4 | Tumbler Switch | Test Coil | 27 | Low Place Value Switch | Low Place Brush Ring |

| 5 | Tumbler Switch | Cam Op. Counter Switch | 28 | High Place Value Switch | High Place Brush Ring |

| 6 | Tumbler Switch | Trip Switch | 29 | High Total Veeder | High Counter Switch |

| 7 | Isolation Fuse | 16 Point Plug | 30 | Show Switch | Win Place Switch |

| 8 | Isolation Switch | Clutch | 31 | Trip Switch | Clutch |

| 10 | Test Switch | Isolation Switch | 32 | Trip Switch | Condenser |

| 12 | Motor | Isolation Switch | 33 | Trip Switch | Trip Coil |

| 13 | Test Switch | Cam Op. Counter Switch | 34 | Trip Switch | Condenser |

| 14 | Test Switch | Veeders (Common) | 35 | Race Change | 16 Point Plug |

| 15 | Show Value Switch | Show Switch | 36 | Show Value Switch | 16 Point Plug |

| 16 | Test Switch | Handle Switch | 37 | Show Value Switch | 16 Point Plug |

| 17 | Test Switch | Value Latch Switch | 38 | High Place Value Switch | 16 Point Plug |

| 18 | Tumbler Switch | Motor | 39 | Low Place Value Switch | 16 Point Plug |

| 19 | Win Place Switch | Place Value Switch | 40 | Low Win Value Switch | 16 Point Plug |

| 20 | Win Place Switch | Win Value Switch | 41 | High Win Value Switch | 16 Point Plug |

| 21 | Low Total Veeder | Low Counter Switch | 43 | Race Change | 16 Point Plug |

| 22 | Win Place Switch | Place Value Switch(Betting) | 44 | Trip Switch | Handle Switch |

| 23 | Win Place Switch | Trip Coil | 45 | Cam Op. Counter Switch | Isolation Fuse |

The numbers in the Wiring Information table above have far greater significance than ordering the items in the list. They all correspond to the numbers on the pads in the circuit diagram above titled J8 Circuit Diagram Randall Park. When I found this table, I thought I could find out where the middle contact of the Handle Switch shown in the circuit diagram above, is connected to as there is no connection shown in the diagram as previously mentioned. Unfortunately, the table agrees with the diagram, showing the left arm of the Handle Switch connected to the Test Switch and the right arm connected to the Trip Switch only, leaving the connection of the middle contact of the switch a mystery. This does gel with the circuit diagram as the diagram shows no number next to the pad of the centre arm of the Handle Switch implying there is no entry for it in the list above.

In the circle in the top left quadrant of the image below the Cam Operated Counter Switch can be seen. Above and to the right of the large circle is a small circle with the number 5 in it pointing to the switch. This is a good example of how a Cam Operated Switch works. At the tips of the contact arms of the switch there is a cam wheel to the left of top dead centre of the circle. The tip of the bottom arm of the switch rides on the perimeter of the circular part of the cam, which pushes it towards the other arm closing the contacts on each arm near the tips. The cam turns as a result of a machine cycle being triggered by a sale and when the flat part reaches the switch, it will temporarily open, as the arms of the switch are springy and the contacts will open when the arms straighten without the force applied by the high part of the cam. This can be seen in the drawing at the bottom of this page titled J8 OPER NO. 31 Randall Park in box number 15. The text in this box reads: Cam operated Counter Switch has Contacts closed when follower on large 0. & open when on small 0. The terminology Large zero and Small zero are interesting. I think it relates to the symbol inside the circle at the centre of the cam. It seems to consist of two concentric circles, the outer is the Large 0 and the inner the Small 0. The Large 0 has a pair of parallel lines inside it which form chord lines to the large circle. The two areas between the chords and their respective arcs of the circle are filled in black. This seems to indicate that when the follower is on the Large 0 or outer circle the contacts on the switch are closed, however in the chord line sections, translated to the cam as being the flat sections where the follower drops towards the Little 0 the contacts open. In conclusion, the switch is being operated by the rotation of a shaft, which in this case is part of the operating cycle of the TIM, so that the switch activates for each transaction on the TIM and that is counted on either the High Total Veeder or the Low Total Veeder. One of the Veeders will be selected, as determined by the value set by the Value Switch.

In the table above, the Cam Operated Counter Switch is mentioned three times. Firstly, for Wire Number 5 the table records the start as the Tumbler Switch and the end as the Cam Operated Counter Switch. As we know the location of the Cam Operated Counter Switch this easily identifies the Tumbler Switch. In the circuit diagram above titled J8 Circuit Diagram Randall Park the Cam Operated Counter Switch is the closest switch to the right hand edge of the image about a quarter of the way down the image from the top. The pad on the left hand arm of this switch is the one labelled 5 which matches the entry in the list above. From there in the circuit diagram, the wire travels left crossing four vertical wires before rising at 45 degrees to join a pad with 5 connections. This pad with 5 connections is the bottom right pad of four belonging to the Tumbler Switch. I thought this was the Tumbler Switch, however this entry in the Wiring Information table confirms this as this switch is not labelled in the Circuit Diagram. Secondly, wire No. 13 in the Wiring Information table above records the Start as the Test Switch and the end as the Cam Operated Counter Switch. This can be seen in the Circuit Diagram from the right hand arm of the Cam Operated Counter Switch descending to the bottom half of the circuit where it turns left to connect with the top contact of the Test Switch. Finally, Wire No. 45 in the Wiring Information table above records the Start as the Cam Operated Counter Switch and the end as the Isolation Fuse. This is rather curious as the previous two entries for the Cam Operated Counter Switch have already been accounted for in the Circuit Diagram above and there are no more connections shown to this switch in it. So looking for Wire No. 45 in the Circuit Diagram, it can be found at the top of the Isolation Fuse mentioned. To locate this fuse, look at the bottom right contact of the 16 Point Plug at the top centre of the Circuit Diagram. Follow this wire right where it then descends and turns right once more for a short distance, where it joins the bottom of the fuse at pad 7. From the upper pad of the fuse, pad 45 a conductor can be seen travelling up then left then down and left again and then through two more down and left steps finally connecting to the centre switch arm of the Counter Switch. This raises the question, does the Counter Switch have anything to do with the Cam Operated Counter Switch? If yes then the relationship is not clear as they both have different names and they look like two separate switches in the Circuit Diagram. If no then the Wiring Information table seems to be wrong regarding Wire No. 45. Or perhaps I am missing something?

In the circle in the top right quadrant of the image below the Win Place Switch can be seen. This shows another method of activating these switches, to the the Cam Operated Counter Switch described in the previous paragraph. Four switch arms can be seen protruding below the body of the switch, in the centre of the Win Place Switch drawing. On the near side of these arms, a triangular plate can be seen pivoted at the apex of the triangle, around which the plate rotates, as a result of changing between Win and Place Pools by using the runner selection arm knob. When the triangle pivot is in its anticlockwise position a pin extending from the bottom right hand end of the triangle, that is located between the two inner pairs of switch arms, pushes the right hand inner switch arm against the right hand outer switch arm causing an electrical connection between the contacts on the right hand pair of switch arms. Conversely when the triangle pivot is in its clockwise position it pushes the left hand inner switch arm against the left hand outer switch arm causing a connection between this left hand pair of switch arms. Another switch system like the one visible exists behind the visible set in the image below. The tips of the left two switch arms of the inner set can be seen peering below the mid section of the hypotenuse of the triangular plate. The pin in the triangular plate activates both the front and rear set of switch arms. This effectively makes a group of four switches which can be seen in the circuit diagram above titled J8 Circuit Diagram Randall Park. Extending the left side of the 16 Point Plug downwards you come across a name, Win Place on top of Switches. To the left of this name is a group of four switches which are the switches seen in the Win Place Switch drawing below. The two left switches have a P between their contacts and the two right switches have a W between them that stand for Win and Place leading to their name Win Place Switch. As all four switch segments have a single activator they have a singular name.

As previously mentioned, changing between Win and Place Pools is achieved by using the knob on top of the runner selection arm. The way this is implemented, I find is a very interesting aspect of these old systems. I always presumed, when looking at the runner selection arm in these old TIMs, that the knob movement radially along the arm, operated a switch in the arm located underneath the knob and that the operation of the switch was carried by electrical wires out of the arm into the rest of the circuitry. On seeing the size of the Win Place Switch in the drawing below, I realised I was wrong. Obviously the mini and micro switches we are accustomed to today, were not available at the time these machines were manufactured, neither was circuitry requiring lesser currents. The movement of the knob on top of the arm is carried out of the arm assembly by a mechanical cable like the old clutch and brake cables on motorcycles, before they became hydraulic, and the brake cables that are still used on bicycles. These have an inner mechanical cable that moves in and out of an outer tube like housing. Unlike these clutch and brake cables however, where a lever pulls the inner cable out and a spring at the other end pulls the cable back once the lever is released or the pressure is reduced, the knob arrangement on the TIM has a sufficiently rigid inner cable that it can be both pulled and pushed by the knob movement. The knob can be seen in the image at the top of this page near the left hand end of the runner selection arm. With this knob pushed to its extremity towards the tip of the arm, the Win Pool is selected and with it moved to its opposite extremity, towards the pivot point, the Place Pool is selected.

This knob is attached to the mechanical cable mentioned, that runs horizontally along the inside of the arm to the pivot point of the arm and then runs down the centre of the spindle on which the arm rotates, eventually exiting the centre of the spindle inside the J8 case, below the baseplate seen in the drawing above titled J8 OPER NO. 7 Randall Park. In the bottom right quadrant of the baseplate shown in that drawing, three cut-outs can be seen, one wide one, parallel to and close to the bottom edge of the baseplate, with another two above it looking somewhat square like. Looking through the left of the two square like cut-outs, the bottom of the runner selection arm spindle can be seen. It is through the bottom of this spindle that the Win Place selection cable extends. The Win Place Switch, shown below in the top right quadrant, will be mounted underneath the baseplate shown in the J8 OPER NO. 7 Randall Park drawing, near this cable protruding from the bottom of the runner selection handle spindle. As the Win Place Switch is screwed onto the Frame in Operation 8, it is not yet installed in the J8 OPER NO. 7 Randall Park drawing above. Consequently, as the Win Place selection cable has not yet been connected to the Win Place Switch it can still be seen in the OPER NO. 7 drawing above. Again, looking through the left of the two square like cut-outs in the base just mentioned, and looking vertically below the bottom tip of the spindle, you can see a small section of the tip of this Win Place selection cable, protruding downwards into the cut-out below, which is on the left hand side of the wide cut-out parallel to and close to the bottom edge of the baseplate, mentioned before. In the Win Place Switch drawing below, a horizontal lever can be seen attached to the triangular plate, both of which pivot on the same spindle. This lever extends left and disappears off the left hand side of the drawing. At the far left hand end of this lever, the inner cable attached to the runner selection arm knob is clamped. When the Win Pool is selected with the knob, this lever rotates the triangular plate clockwise closing the two Win Pool contact pairs on the left and when the knob is placed in the Place Pool position it rotates the triangular plate anticlockwise closing the two Place Pool contact pairs on the right. Having mentioned that the cable attached to the runner selection arm knob is clamped at the far left hand end of the lever that operates the Win Place Switch, this lever seen disappearing off the left hand side of the drawing top right in the image below, can also be seen top left in the drawing labelled Cam Operated Counter Switch, which fortunately shows the other end of the lever, although it is from the rear side of it which does not really matter, showing the connection between the lever and the Win Place selection cable. It is fortunate that the Cam Operated Counter Switch is located near to the Win Place Switch activation arm. So, on the right hand side of the top left drawing in the image below, a large nut can be seen. This is the securing nut of the runner selection arm pivot and the cable extending from the centre of the pivot, is the Win Place selection cable. A short distance above the nut a clamp can be seen on the cable and this clamp is attached to the tip of the Win Place Switch activation lever, which joins the end of the lever disappearing off the left hand side of the drawing shown top right in the image below.